Chapter Four

4 - 4

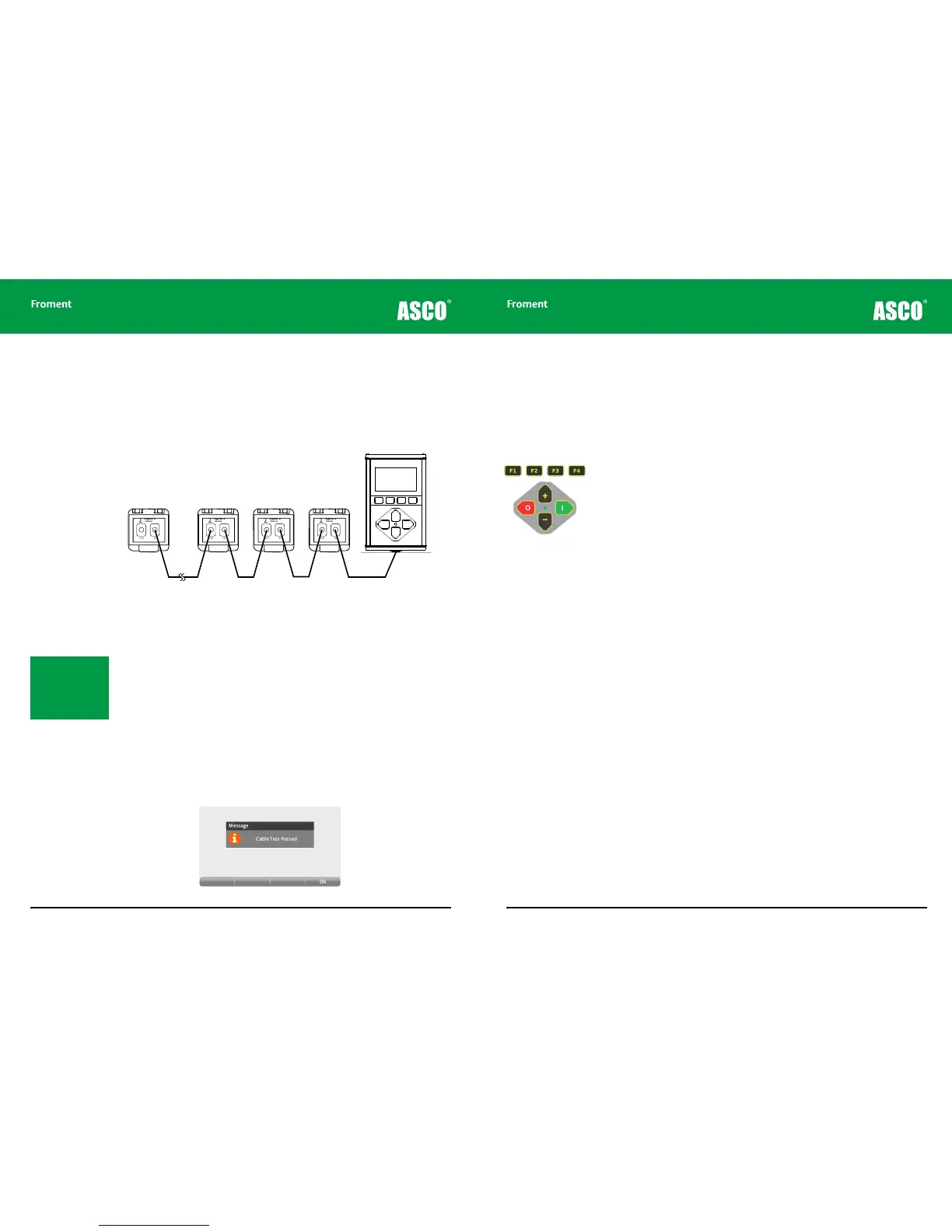

Connecting the Hand-held to the Load Bank

The Hand-held connects directly to the load bank’s Sigma control “in” socket using a

Sigma control cable which can be up to a kilometre in length.

The Hand-held can connect to and control up to 14 load banks at the same time. The load

bank units are interconnected using a daisy chain arrangement as shown in Figure 4-2.

Figure 4-2 The Hand-held Sigma control cable connecting multiple units in a daisy

chain arrangement

Setting the load bank number

Each load bank connected must have a unique number in the range from 1 to 14. The default

number for a particular load bank is assigned during manufacture or on commissioning. If

there is a number selector switch on the load bank this can be used to change the number

to any value from 1 to 11. Setting the selector switch to 0 selects the default number as

stored in the load bank.

Sigma control cable testing

With the addition of a small, mains powered adaptor, the Hand-held can be used as a

Sigma control cable test unit. This provides a fast method of identifying control cable

faults. Contact Froment’s Sales department for more details on this.

OUT IN

Sigma 2

Control

∑

OUT IN

Sigma 2

Control

∑

OUT IN

Sigma 2

Control

∑

OUT IN

Sigma 2

Control

∑

Load Bank

n

Load Bank

3

Load Bank

2

Load Bank

1

Note: Voltage and fre-

quency instrumentation

displayed on the Hand-

held display is taken

from the load bank with

the lowest number.

© NJ Froment & Co. Ltd. This document may not be copied

or disclosed in whole or part without prior writte n authority.

4 - 5

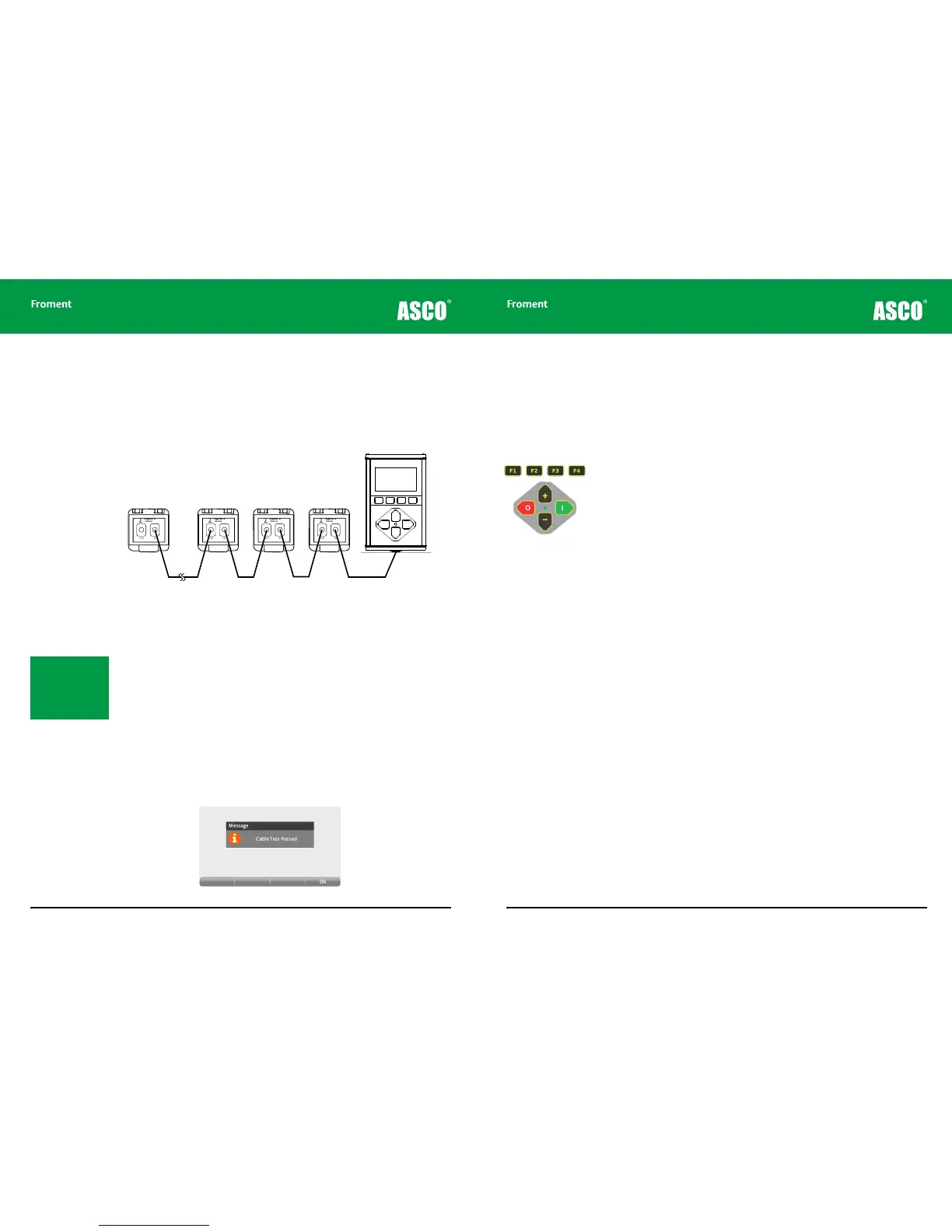

The Hand-held Keypad

The keypad contains eight membrane switches and a single LED indicator. The switches

provide four function keys (marked F1 to F4) arranged below the screen and a quadrant of

four control keys arranged around the LED.

The function keys

The operation of the function keys is context dependant. A menu bar, containing labels

for each of the keys, appears at the bottom of the screen. The labels for each function key

change to indicate the function (PAGE, EDIT, etc.) in the particular context.

The quadrant keys

The four quadrant keys are used to make adjustments, to apply or reject a load, or to start

an automatic test sequence if one is configured.

The + and – keys are used to increase or decrease values that are highlighted or displayed

on screen.

Pressing I applies load if in Manual Test mode, or starts an automatic test if in Automatic

Test Mode.

If a load is already applied pressing I forces the Hand-held to carry out a load correction

(that is to say that it will adjust the number of load elements applied to correct for changes

in voltage or temperature, etc.).

Pressing O at any time will reject the load or abort any automatic load test that is running.

If the load is set to ramp down on reject (indicated by fast blinking of the green LED)

pressing O a second time will drop the remaining load immediately.

The LED status lamp

The LED indicator provides feedback of the current load status:

Continuously On. Load applied (manual mode) or test sequence paused (automatic mode)

Half Second Blink. Automatic test running

Rapid blinking. Ramping down on reject

Chapter Four

Loading...

Loading...