Activation M0212

By-pass function M0941

Default value: Function not active

Setting values:

Function not active

Bypass function deactivated.

Function active

Bypass function activated.

8.11.2. By-pass application: configure

The actuators for the two MOVs (valves) have to be configured according to their

application (main or by-pass valve).

Customer settings M0041

By-pass function M0942

By-pass application M0943

Default value: Main valve

Setting values:

Main valve

Actuator for main valve.

By-pass valve

Actuator for by-pass valve.

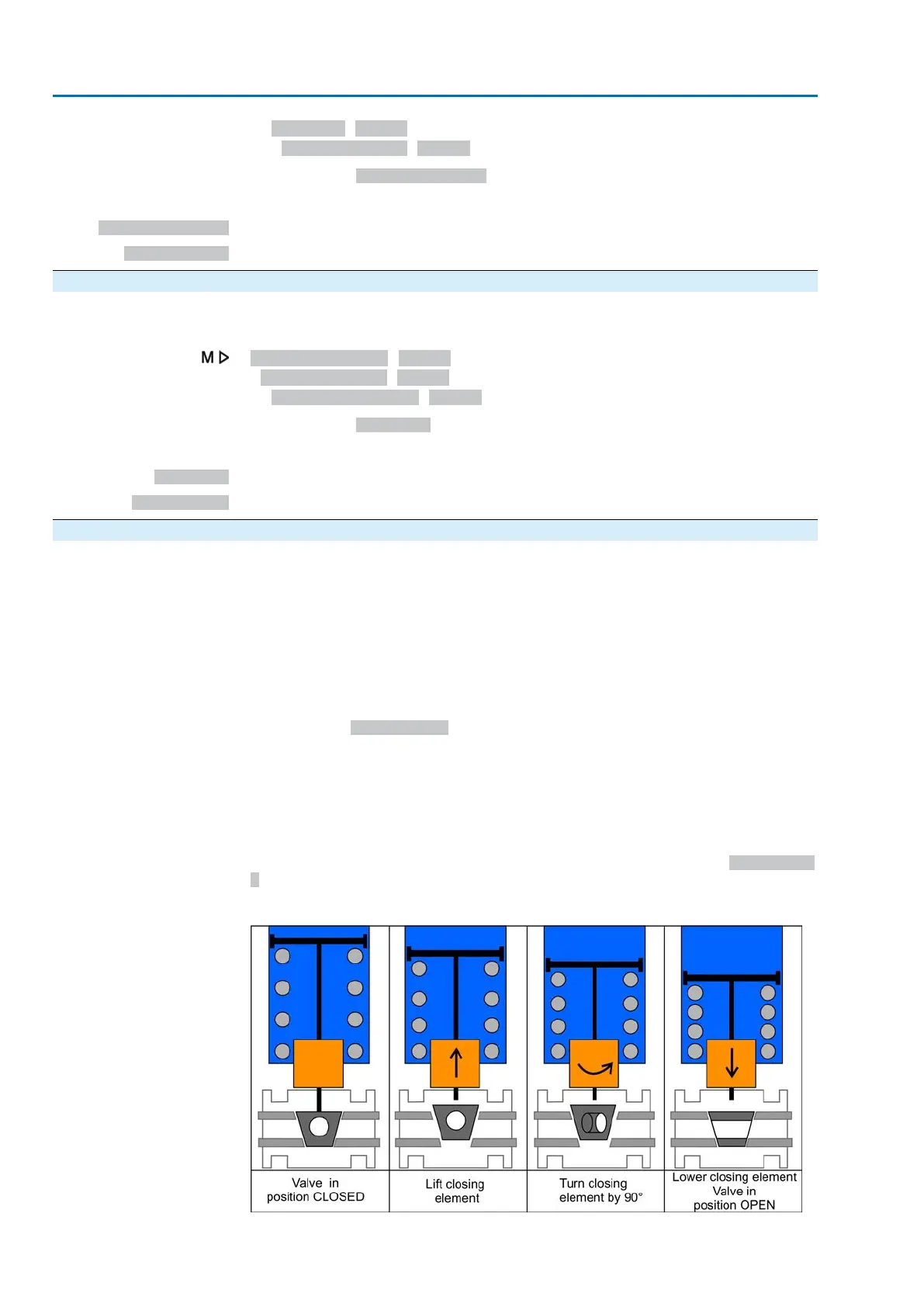

8.12. Lift Plug Valve (LPV)

Application

A "Lift Plug Valve" is a special valve whose closing element must first be lifted out

of its seat or locking position before being rotated for opening or closing the valve.

Valve locking and/or pressure relief prior to rotation of the closing element can thus

be implemented. Once the end position has been reached, the closing element has

to be lowered again. Such valves are particularly suited in case of significant pressure

differences (pressure relief) and safety-related systems (locking).

Requirements

●

Two actuator controls and actuators are required, one of them is considered

as master actuator (MA), the other one as slave actuator (SA).

●

The actuator controls of the master actuator require an additional <Parallel in-

terface > I/O Interface 2.

Function

Due to the special design of the LPV valves, they can only be operated in

OPEN-CLOSE duty (no modulating duty). For this type of duty, two actuators are

required which are operated as a master-slave-system with main actuator (rotary

movement) and slave actuator (stroke movement). However, only one actuator or

actuator controls are "visible" at the DCS, i.e. the slave actuator is completely

controlled and monitored by the master actuator. Communication between master

and slave actuator is performed via the additional <Parallel interface> I/O Interface

2.

Figure 43: Schematic representation of the function of a Lift Plug Valve

68

Actuator controls

Application functions AC 01.2/ACExC 01.2 Profinet

Loading...

Loading...