CB (E7) 06/2018 Page 138/174

Recommended precautions: To protect the eyes use sealed protective goggles.

CAUTION

Eye contact.

Eye damage due to chemical burns.

∅ Do NOT empty into drains.

Wear protective goggles.

Following frequent use of the disinfectant spray and prior to hot-air sterilization, remove any

agent remainder by using the neutral cleaning agent and then a moistened towel to avoid

formation of permanent residues.

After using the disinfectant spray, allow the chamber to dry thoroughly, and aerate it

sufficiently.

21.3 Hot-air sterilization at 180 °C / 356 °F

The very first sterilization after operation may cause an odor. This is not a quality defect. We

recommend ventilating well the room during sterilization.

21.3.1 Overview

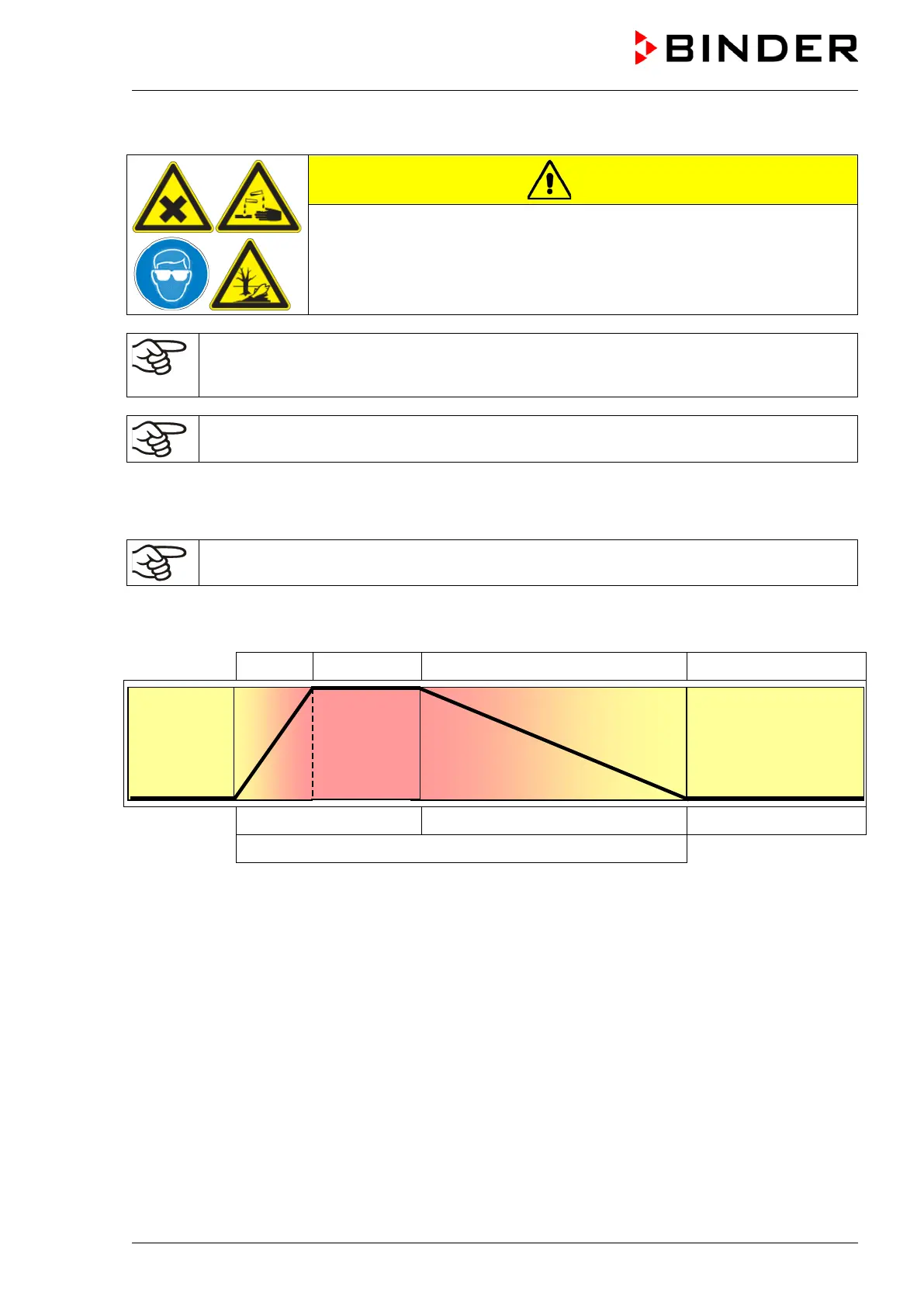

Holding Cooling down Equilibrating

4 hours 6 hours

unlimited

Sterilization cycle of 10 hours

Figure 29: Setpoint profile during the sterilization cycle

The chamber can perform an automatically controlled hot-air sterilization cycle. This procedure will take

approx. 10 hours and consists of the following steps:

• Heating up phase: The chamber heats up the inner chamber as fast as possible to the sterilization

setpoint temperature

• Holding phase: Constant sterilization setpoint temperature

The sterilization setpoint temperature is pre-set in factory to 187.5 °C / 369.5 °F. The duration of the

heating up and holding phase is in total 4 hours. This ensures that 180 °C / 356 °F is maintained on all

internal surfaces for at least 30 minutes

• Cooling down phase: Programmed duration of 6 hours until 37 °C / 98.6°F is reached

• Then follows an equilibration phase: After the 10-hour sterilization cycle the controller changes to

fixed value operation mode and equilibrates to the set-point which has been entered there (e.g., 37 °C

/ 98.6 °F).

Loading...

Loading...