45 MT55 Operation & Maintenance Manual

ATTACHMENTS (CONT’D)

Installing And Removing The Attachment (Common Industry Interface) (Cont’d)

Installing (Cont’d)

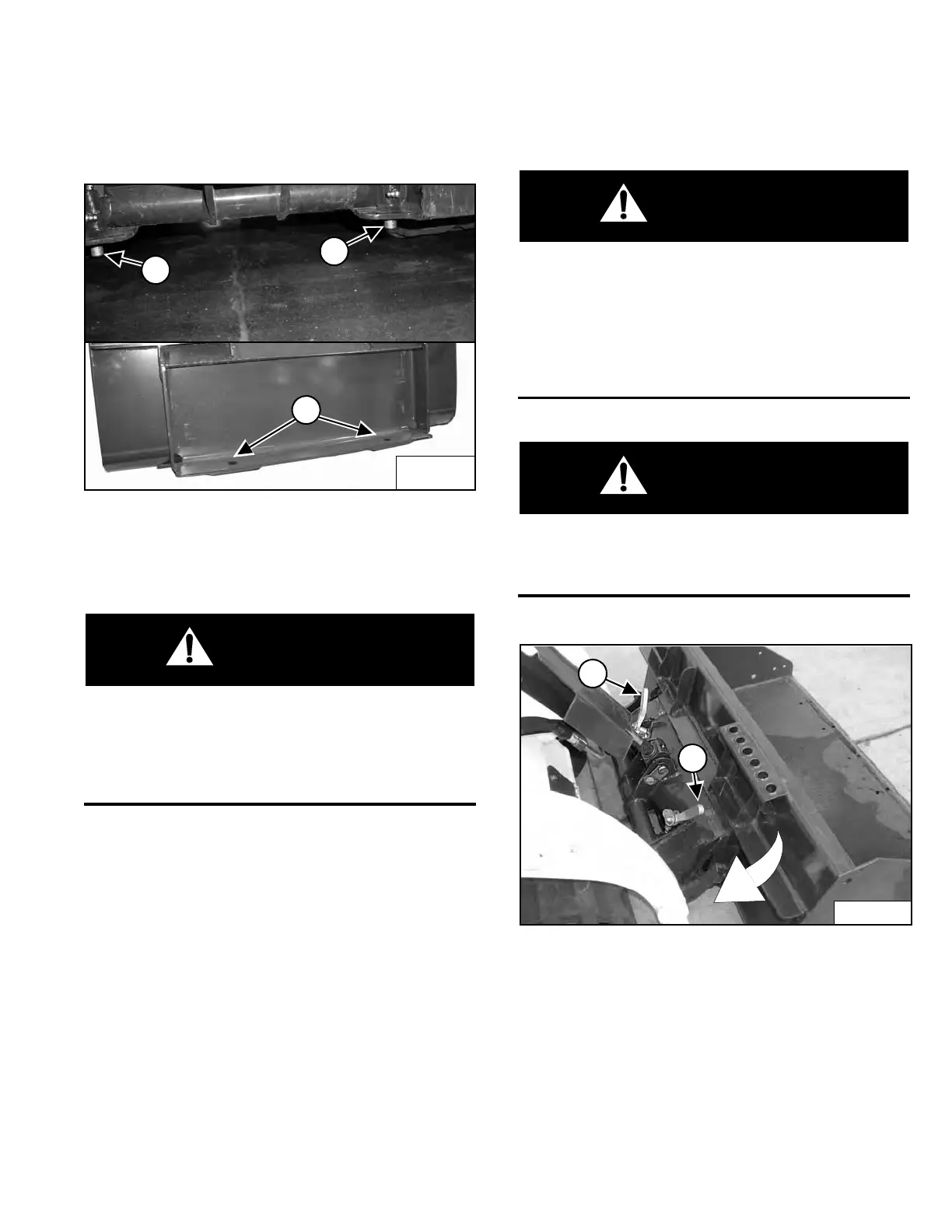

Figure 48

The pins (Item 1) must extend through the holes in the

mounting frame of the bucket (or other attachment) (Item

2) [Figure 48], securely fastening the attachment to the

interface.

The Common Industry Interface locking pins must

extend through the holes in attachment frame.

Levers must be fully down and locked. Failure to

secure the locking pins can allow attachment to

come off and cause serious injury or death.

W-2996-1015

Removing

Lower the lift arms, put the attachment flat on the ground

and lower or close the hydraulic equipment.

Stop the engine and engage the parking brake.

If the attachment is hydraulically controlled (combination

bucket, tiller, etc.) stop the engine and relieve hydraulic

pressure at the quick couplers. (See Relieve Hydraulic

Pressure (Mini Track Loader And Attachment) on Page

31.) Disconnect auxiliary hydraulic hoses.

Before you leave the operator’s position at the rear of

the loader:

• Lower lift arms and put attachment flat on

ground.

• Disengage auxiliary hydraulic system.

• Engage parking brake.

• Stop engine. Remove key.

W-2416-1015

Locking pin levers have spring tension. Hold lever

tightly and release slowly. Failure to obey warning

can cause injury.

W-2997-1015

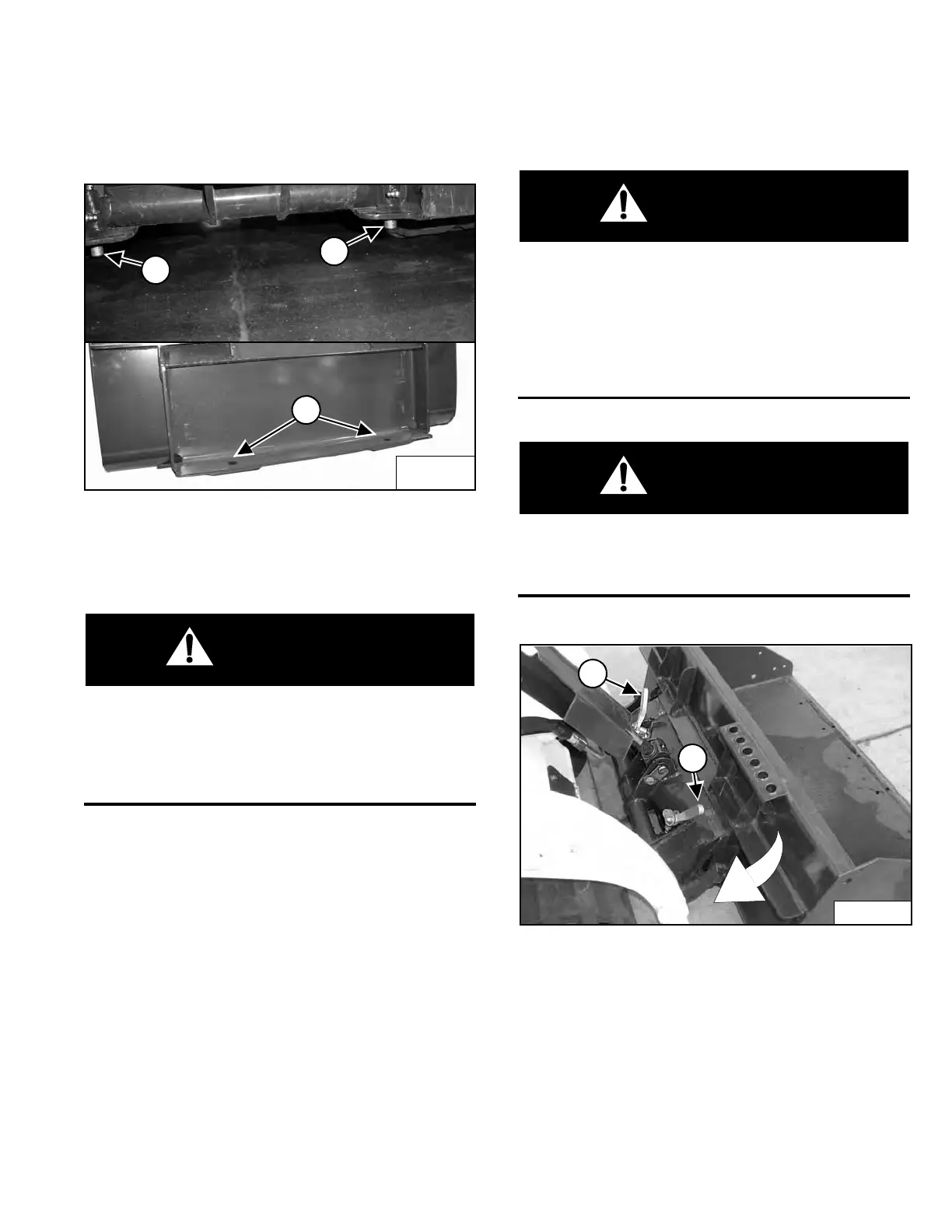

Figure 49

Pull the CII locking pin levers (Item 1) [Figure 49] all the

way up.

Perform the PRE-STARTING PROCEDURE. (See PRE-

STARTING PROCEDURE on Page 37.) Start the engine.

Release the parking brake.

Be sure the lift arms are all the way down. Tilt the Bob-

Tach forward. Move backward, away from the bucket or

attachment.

Dealer Copy -- Not for Resale

Loading...

Loading...