TRANSMISSION

KUKJE MACHINERY CO., LTD.

102

5. CHECKING, DISASSEMBLING AND SERVICING

< Clearance between differential pinion shaft and

differential pinion >

1. Measure the differential pinion shaft O.D. with an

outside micrometer.

2. Measure the differential pinion I.D. with an inside

micrometer, and calculate the clearance.

3. If the clearance exceeds the allowable limit,

replace faulty parts.

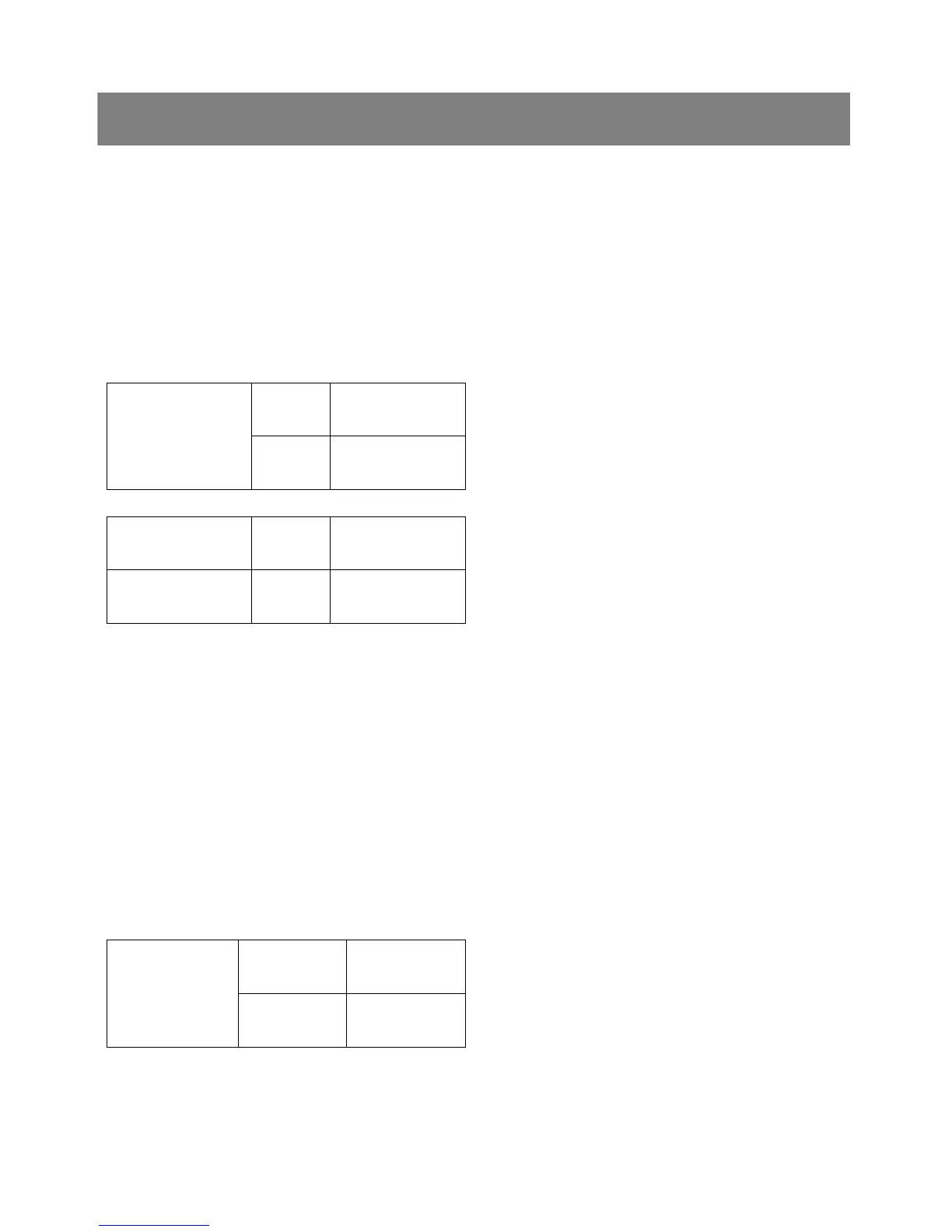

Factory

spec.

0.016 to 0.045 mm

0.0006 to 0.0018 in.

Clearance between

differential pinion shaft

and differential pinion

Allowable

limit

0.30 mm

0.0118 in.

Differential pinion I.D.

Factory

spec.

16.000 to 16.018 mm

0.6299 to 0.6306 in.

Differential pinion

shaft O.D.

Allowable

limit

15.973 to 15.984 mm

0.6289 to 0.6293 in.

< Backlash between differential pinion and

differential side gear >

1. Secure the differential case with a vise.

2. Set the dial indicator(lever type) with its finger in

the tooth of the differential side gear.

3. Press differential pinion and side gear against

the differential case.

4. Hold the differential pinion and move the

differential side gear to measure the backlash.

5. If the backlash exceeds the allowable limit, adjust

with differential side gear shims.

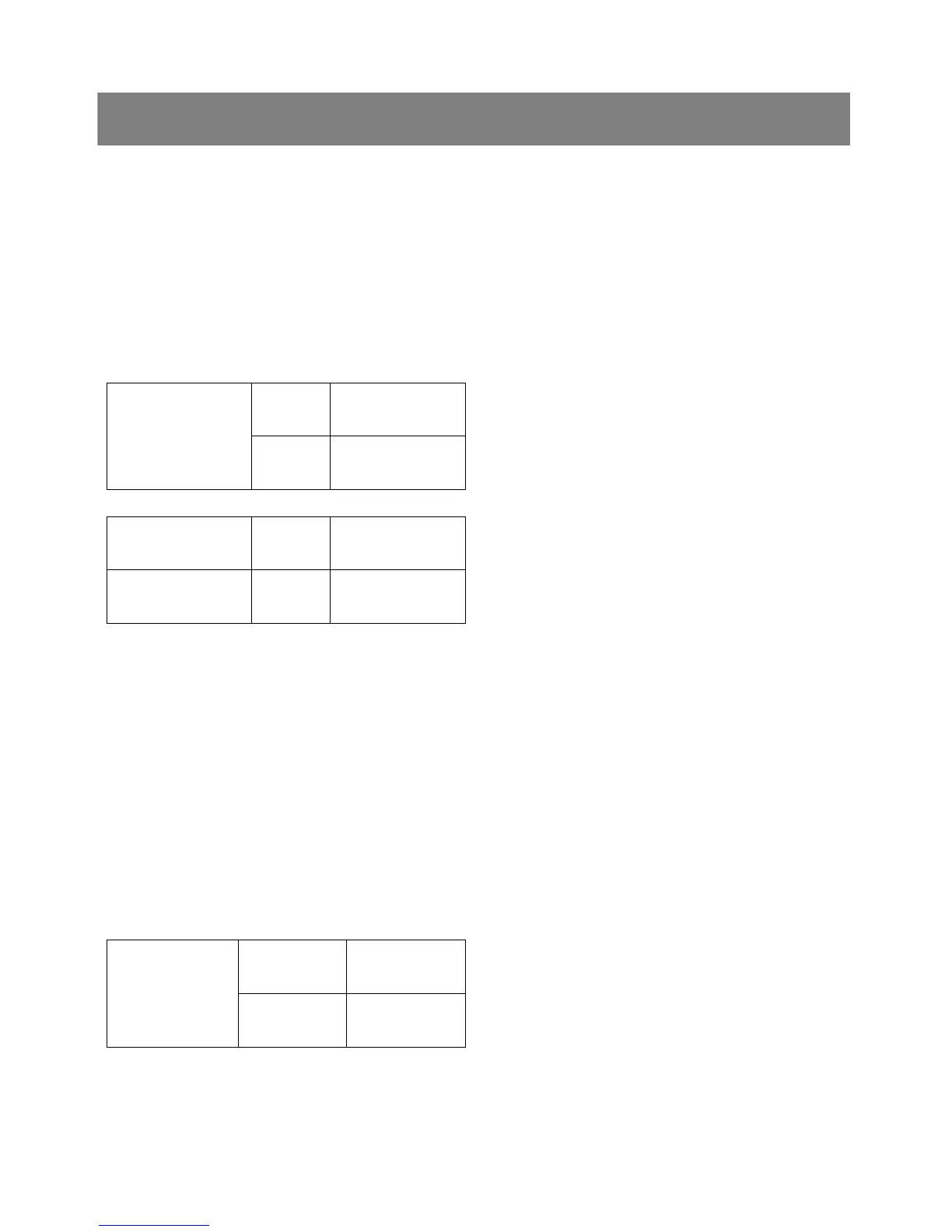

Factory spec.

0.1 to 0.3 mm

0.004 to 0.012 in.

Backlash between

differential pinion

and differential

side gear

Allowable limit

0.4 mm

0.016 in.

#. Thickness of shims : 0.8mm(0.0315 in.),

1.0mm(0.0394 in.), 1.2mm(0.0472 in.)

Loading...

Loading...