TRANSMISSION

KUKJE MACHINERY CO., LTD.

97

4. CHECKING, DISASSEMBLING AND SERVICING

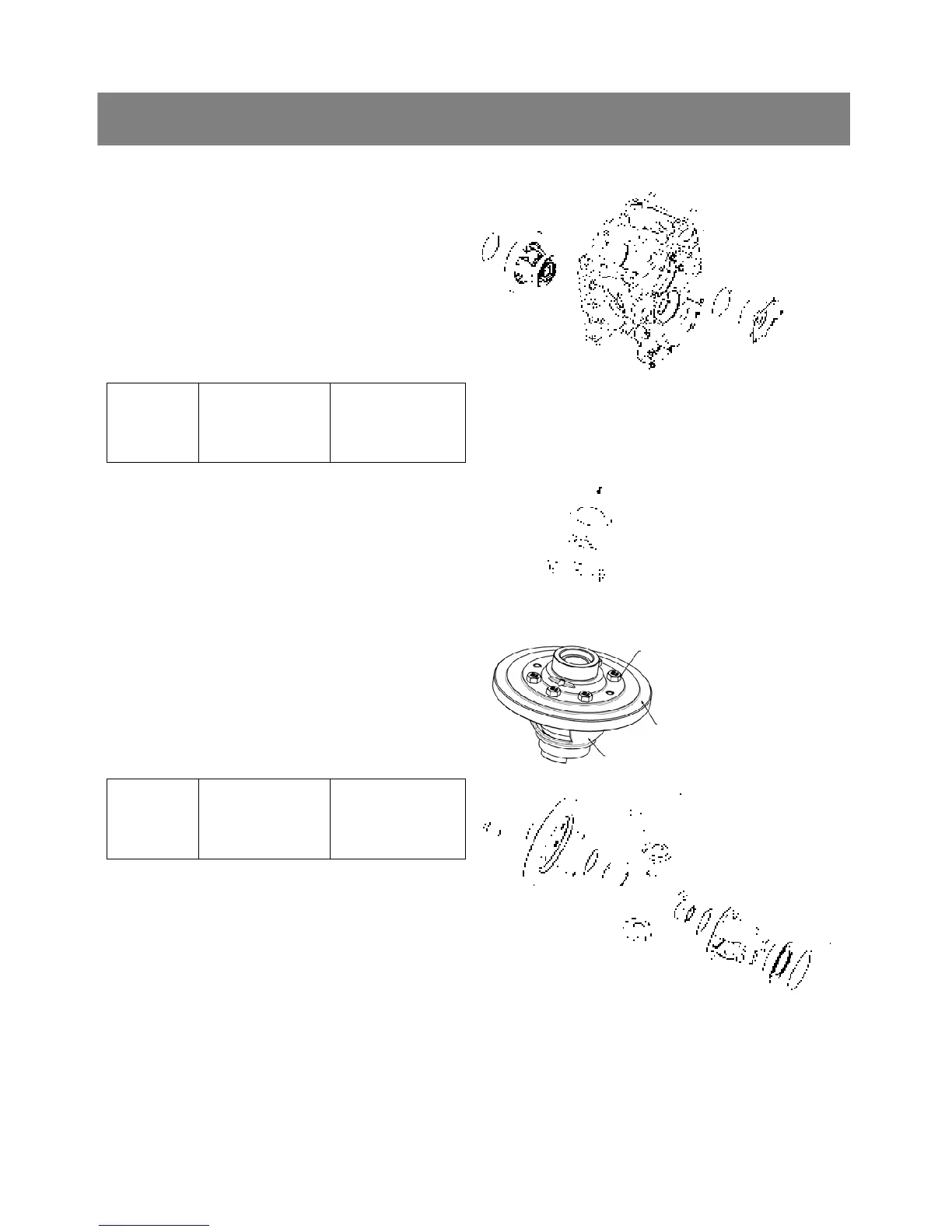

*. PART NAME

1) Bearing holder 2) Adjusting shim

3) Differential gear assembly

< Differential gear assembly >

1. Remove the bearing holder mounting screws and

remove the bearing holder(1).

2. Take out the differential gear assembly(3).

▷ Reassembling

9 Install the differential gear assembly, noting the

number of shims(2) in the differential case left

side and bearing holder side.

Tightening

torque

Differential gears

bearing holder

mounting screw

23.5 to 27.5 Nm

2.4 to 2.8 kgfm

17.4 to 27.3 ft-lbs

< Bearing >

1. Remove the right and left bearings from in the

differential case.

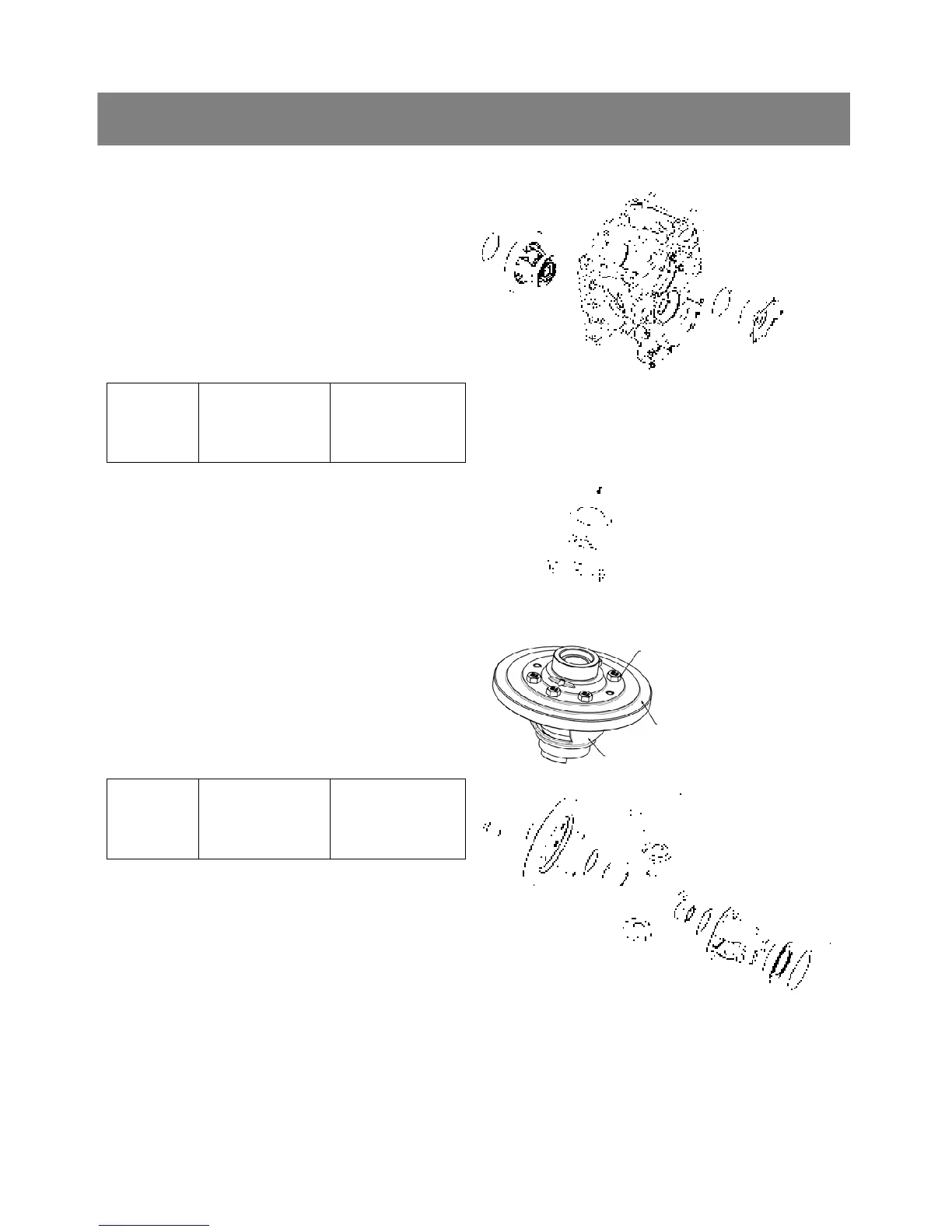

< Spiral bevel gear >

1. Remove the spiral bevel gear UBS screws(1).

2. Remove the spiral bevel gear(2) from differential

case(3).

▷ Reassembling

9 Apply liquid lock to the spiral bevel gear UBS

screws.

Tightening

torque

Spiral bevel gear

UBS screw

29.4 to 34.3 Nm

3.0 to 3.5 kgfm

21.7 to 25.3 ft-lbs

< Differential side gear and differential pinion >

1. Put parting marks on the differential

pinion(1) and the differential side gear(2).

2. Tap out the dowel pin(3).

3. Remove the differential pinion shaft.

4. Remove the differential pinion(4), differential

side gear(2) and shim(5).

▷ Reassembling

9 Install the differential pinion and differential side

gear, aligning the parting marks.

*. PART NAME

1) Spiral bevel

gear UBS screw

2) Spiral bevel gear

3) Differential case

*. PART NAME

1) Differential pinion 2) Differential side gear

3) Dowel pin 4) Differential pinion

5) Shim

(2)

(3)

(2)

(1)

(1)

(2)

(3)

Loading...

Loading...