CTR9 Car-O-Liner Group AB

49023, EN - rev. 4, 2020-01 103

7.2 Maintenance

The amount of use and the working environment should be taken into con-

sideration when planning the frequency of maintenance for the welder.

Careful use and preventive maintenance will help you to ensure trouble-free

operation.

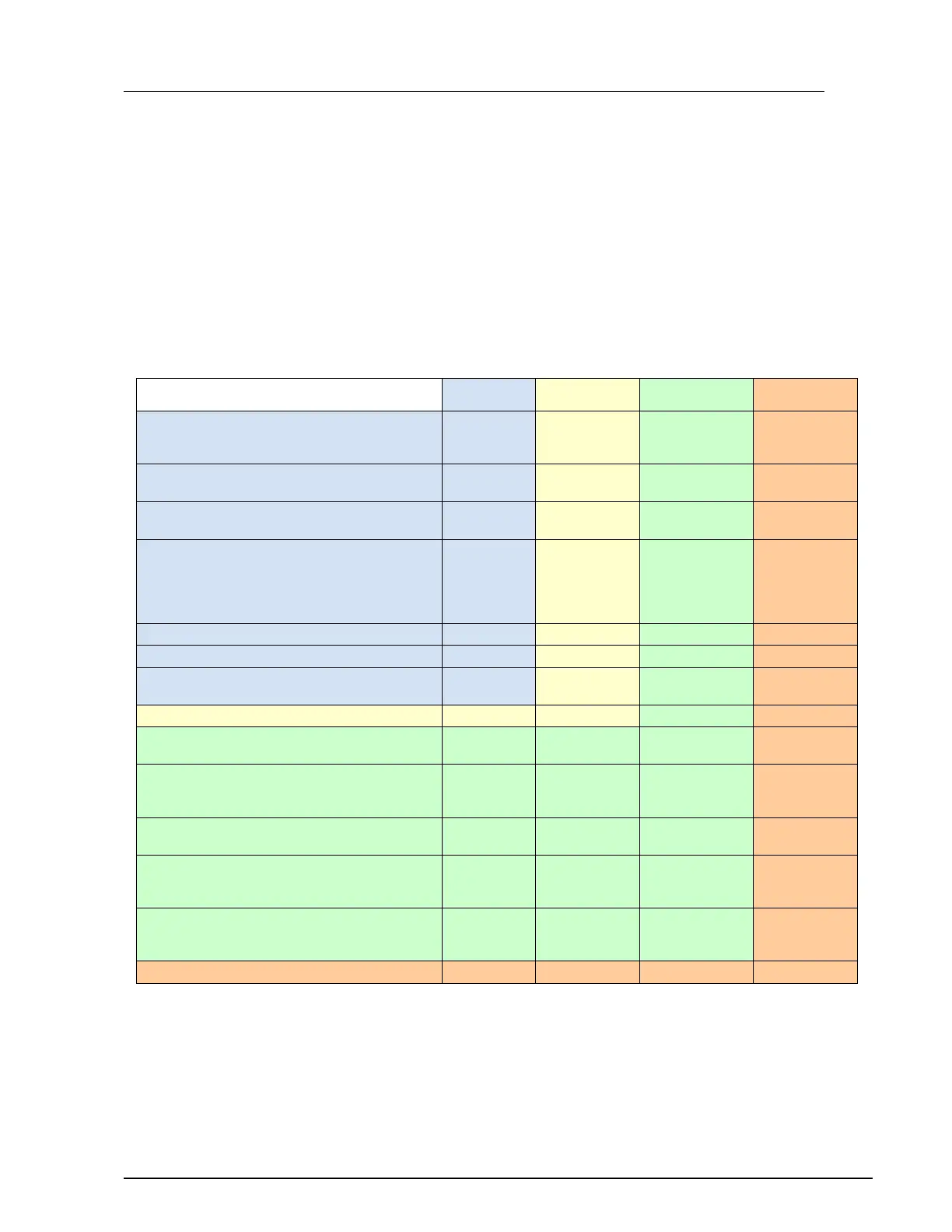

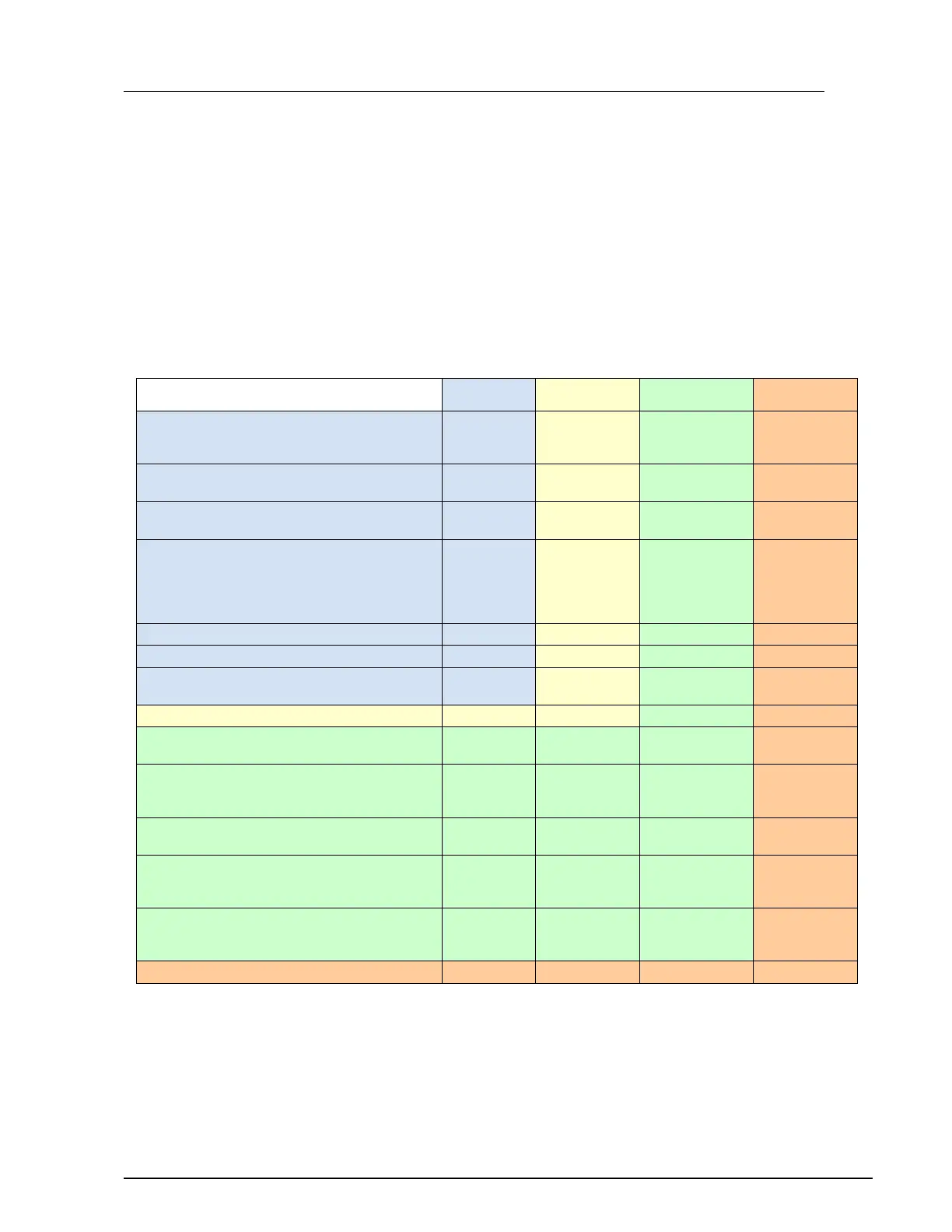

Follow the Inspection plan below for correct inspection

intervals and service actions:

Daily

inspection

Weekly

inspection

Monthly

inspection

Annual

inspection

Check condition of C-tong, air connections and air

hoses to prevent overheating and malfunction due

to poor cooling

Check condition of welding cables.

Do not use faulty cables

Check that mains connection cables are safe and in

compliance with local regulations

Check that all welding caps are in good

condition.

Cleaning with Scotch-Brite Hand Pads.

Use a tip dresser to maintain the proper shape.

Change caps if necessary

Check coolant level

Check support arm cord

Check function of support arm spring

and locking mechanism

Clean air filters, see figure 7.1 on the following page

Change coolant and high-tech anti freeze,

see 3.7 Filling of cooling liquid

Check possible oxidation since it may cause contact

resistance in the welding circuit. Remove oxidation

swith fine sandpaper if necessary

Check cooling tubes. Each cap holder electrode has

a specific coolin tube that goes in it

Clean the spot welder and remove dirt and metal

particles that might be attracted by the machine´s

magnetic field

Check all screws on electrode yokes, electrode

holders, plates, rigid and flexible junctions.

Tighten if necessary

Completely drain off and replace coolant

Loading...

Loading...