Car-O-Liner Group AB CTR9

88 49023, EN - rev. 4, 2020-01

6.10.5 Single spot welding

The maximum electrode-side sheet thickness is 1.5 mm; the thickness of the

sheet on the opposite side should however be higher. Prior to welding, en-

sure that the sheets are perfectly clean and close lying.

For optimum results, use a single spot electrode in good condition (with

rounded tip) and with a maximum electrode tip diameter of between 3.5 and

4.5 mm; you can also use a suitable electrode cap.

Always attach the work piece clamp to the lower sheet or, if the weld zone

cannot be accessed from the rear, press the work piece clamp against the rear

plate by using the copper lug that was delivered together with the other

equipment. Already welded spots produce a parallel resistance, and thus an

energy loss. To reduce this loss to the greatest possible extent, the following

spots must be welded in direction to the ground clamp.

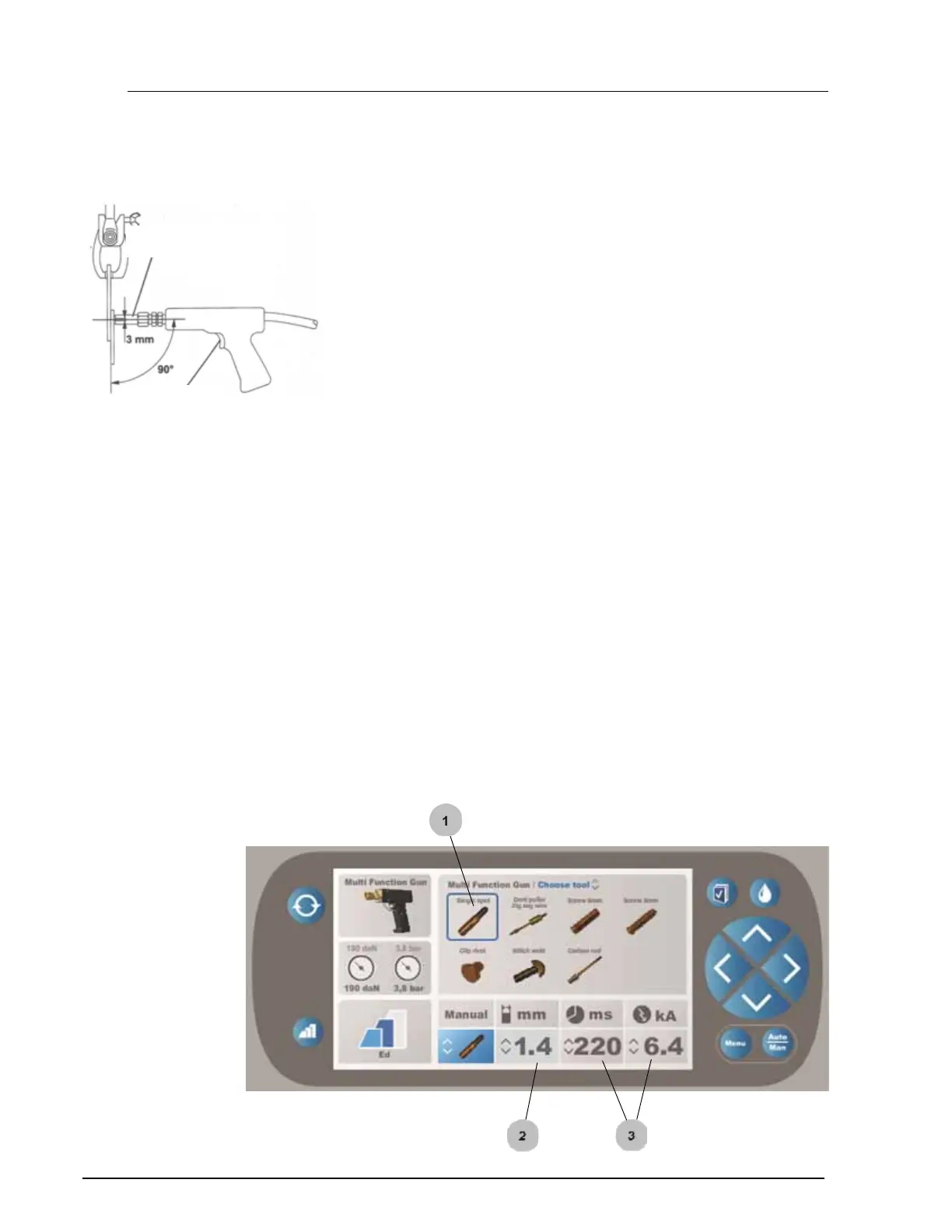

Place the gun with the single spot electrode at right angle onto the sheets to

be welded, press strongly (approx. 80 kg) against the sheets and activate the

trigger. (See figure above).

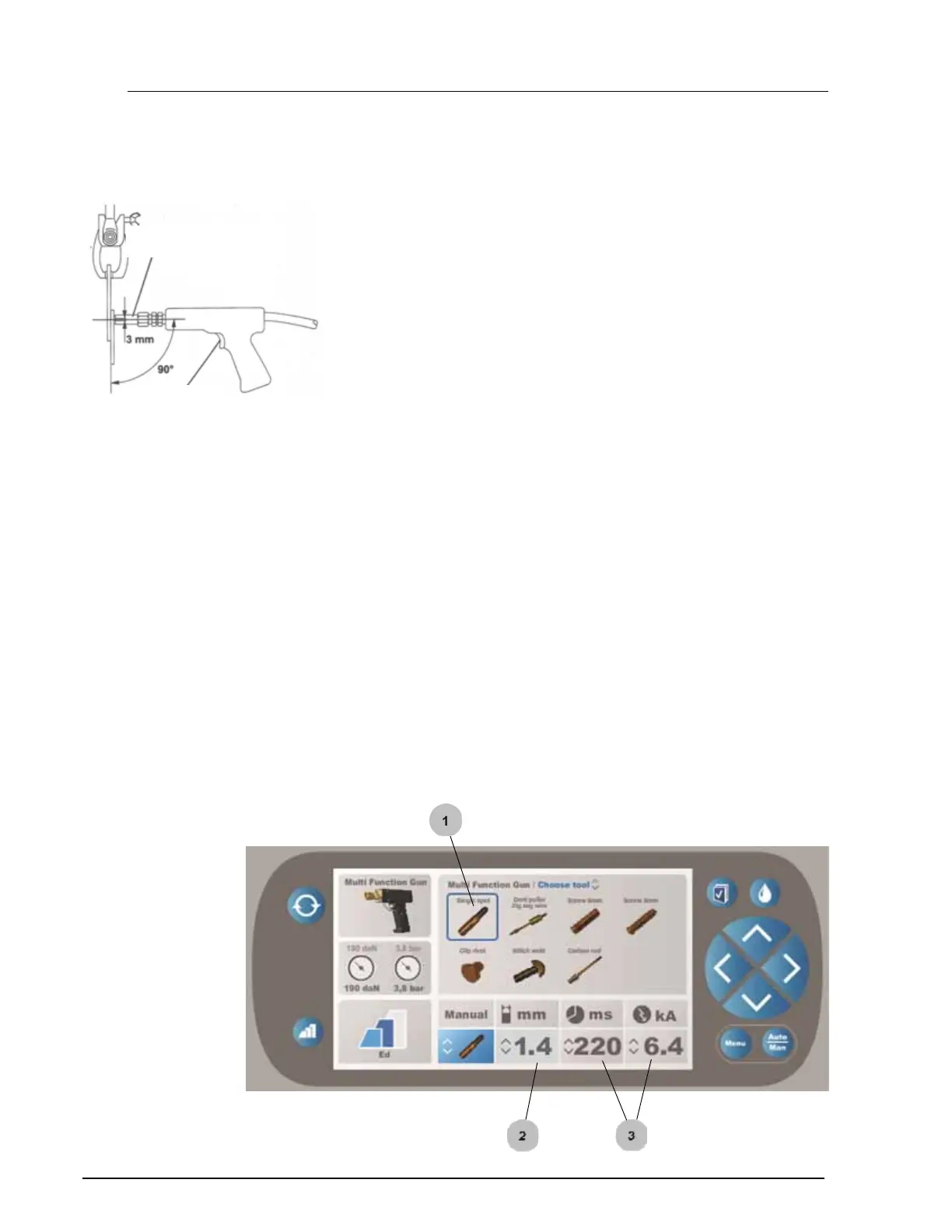

Reference and welding values are automatically set by the chosen material

thickness.

1. Select "Single spot" tool by pressing the "up/down" button.

2. Set the total sheet material thickness. Welding time and current will

be automatically set ("right/left" button)

3. Manual setting of welding time and current ("up/down" button).

Single spot electrode

Trigger

Loading...

Loading...