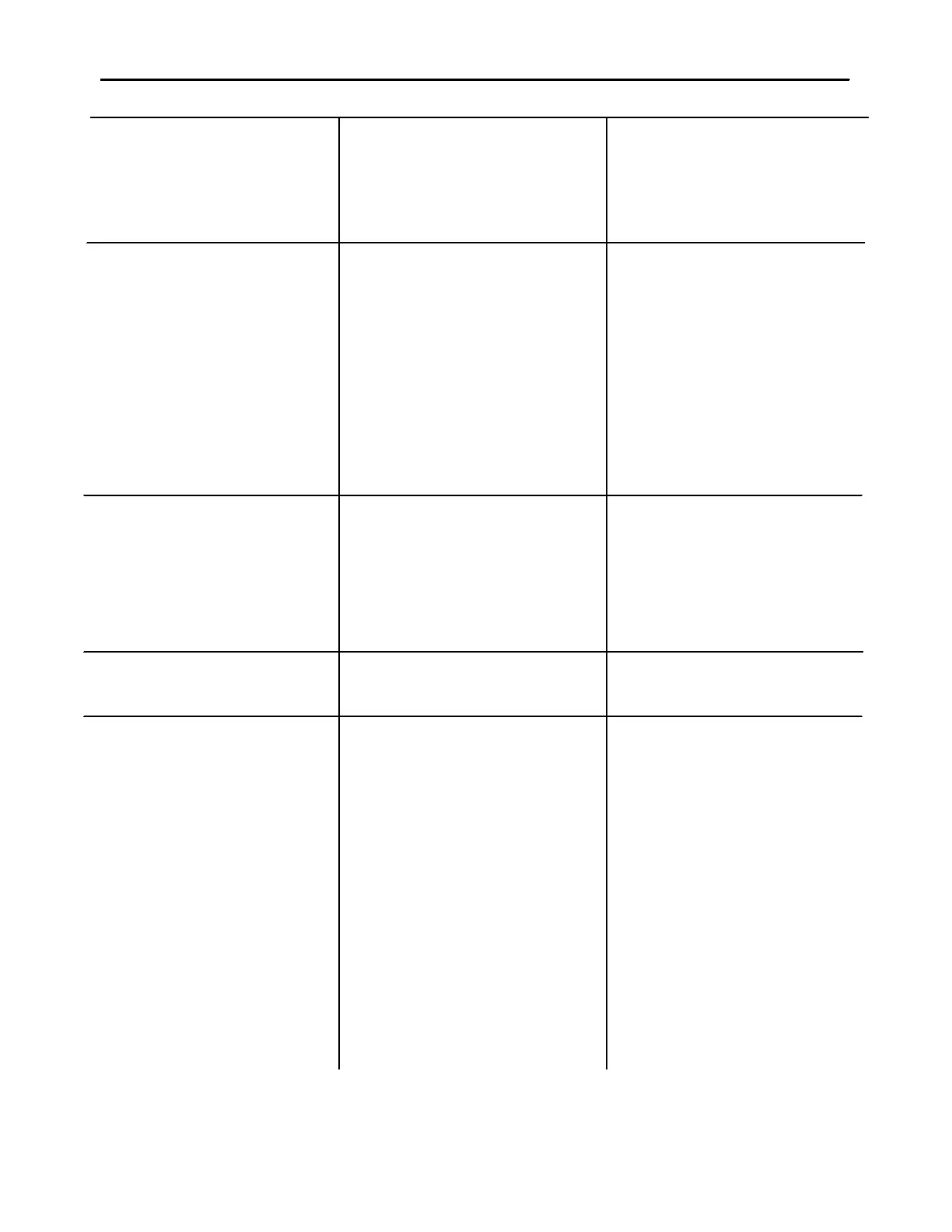

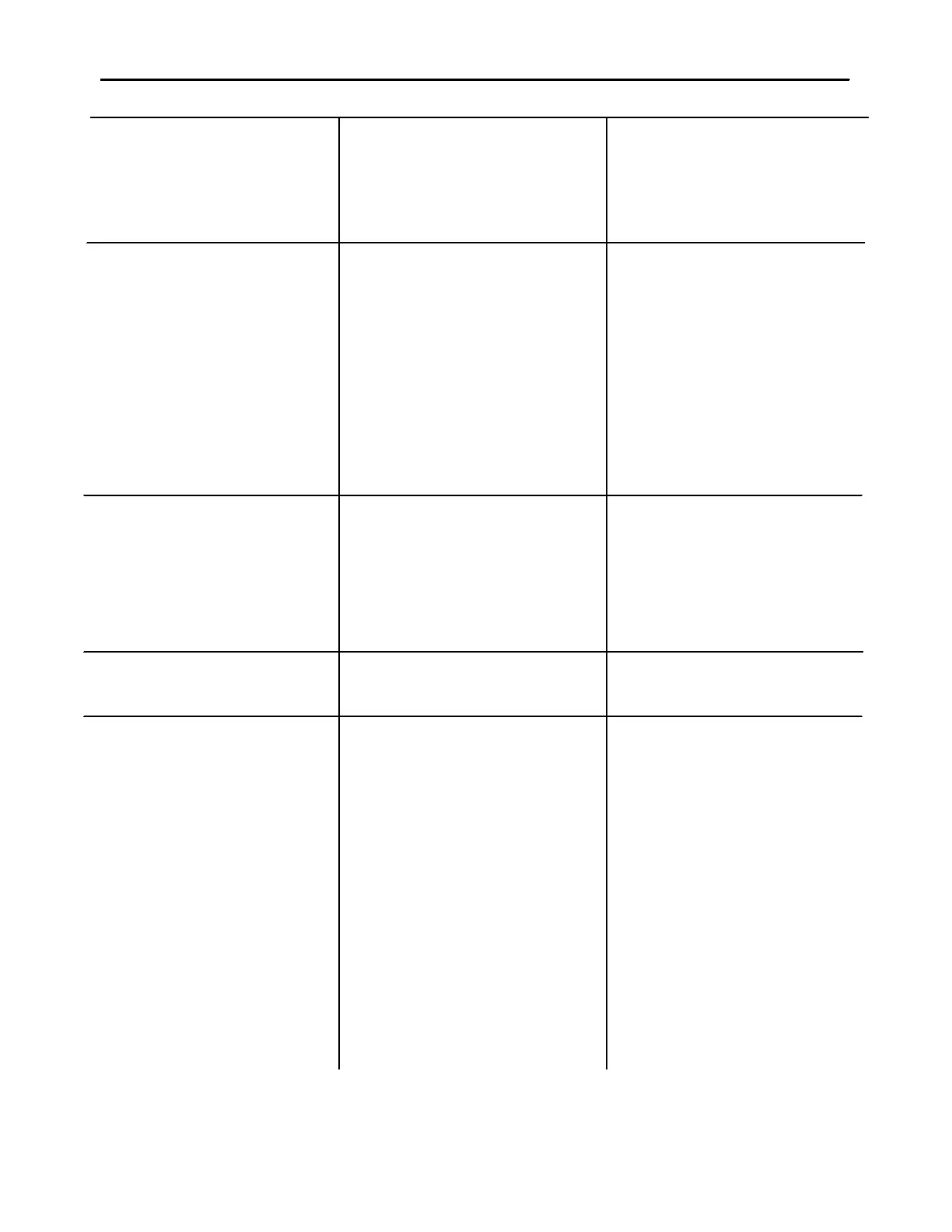

SECTION 00 -- GENERAL INFORMATION -- CHAPTER 4

00-2

PROBLEM POSSIBLE CAUSE CORRECTION

Vibration.

Cutter bar not floating.

Machine breaking back too

easily.

Difficulty in obtaining correct

angle on cutter bar.

Uneven stubble/streaking.

PTO shaft or U-joint damage.

Material buildup in cutter bar drums.

Cutter bar components damaged or

missing.

Main frame setting incorrect.

Cutter bar pivot points binding.

Flotation system not engaged.

Flotation spring adjustment.

High stubble kit installed.

Insufficient tension on breakaway

spring.

Ground speed too fast for crop

conditions.

Insufficient cutter bar flotation.

Lack of adjustment on top link.

Too much tilt on cutter bar.

Low PTO speed.

Excessive forward speed.

Knives dull or broken.

Knives stuck under disc.

Knives installed on wrong discs.

Drive belt loose.

Inspect and repair PTO shaft.

Remove top cover and clean out

drums.

Inspect and repair components.

Adjust check chains to carry main

frame 18″ (450 mm) from ground and

parallel.

Clean and lubricate pivot points.

Install jack pin into flotation spring

upper rod.

Adjust flotation spring tension.

Readjust check chains to carry main

frame 20″ (508 mm) from ground and

parallel.

Tighten breakaway spring until nut

bottoms out.

Reduce ground speed.

Check and adjust flotation

system.

Reposition top link to rear hole in

main frame.

Reduce tilt.

Run PTO at 540 RPM. (Do not over-

speed)

Reduce forward speed.

Install new knives.

Straighten or replace knives.

Install knives on correct discs.

Tighten drive belt spring to

correct length.

Loading...

Loading...