Chapter 3 – Installation & Wiring

3-8

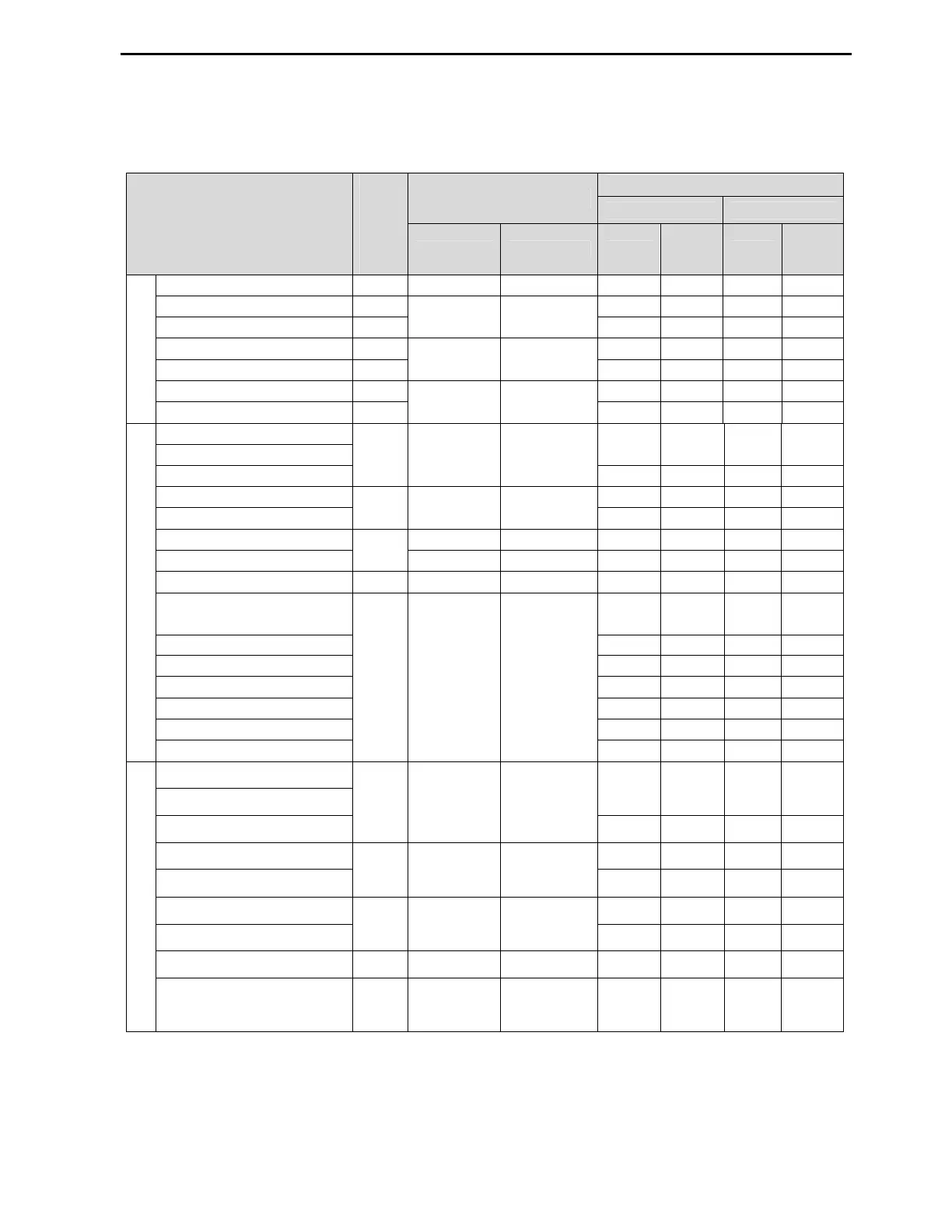

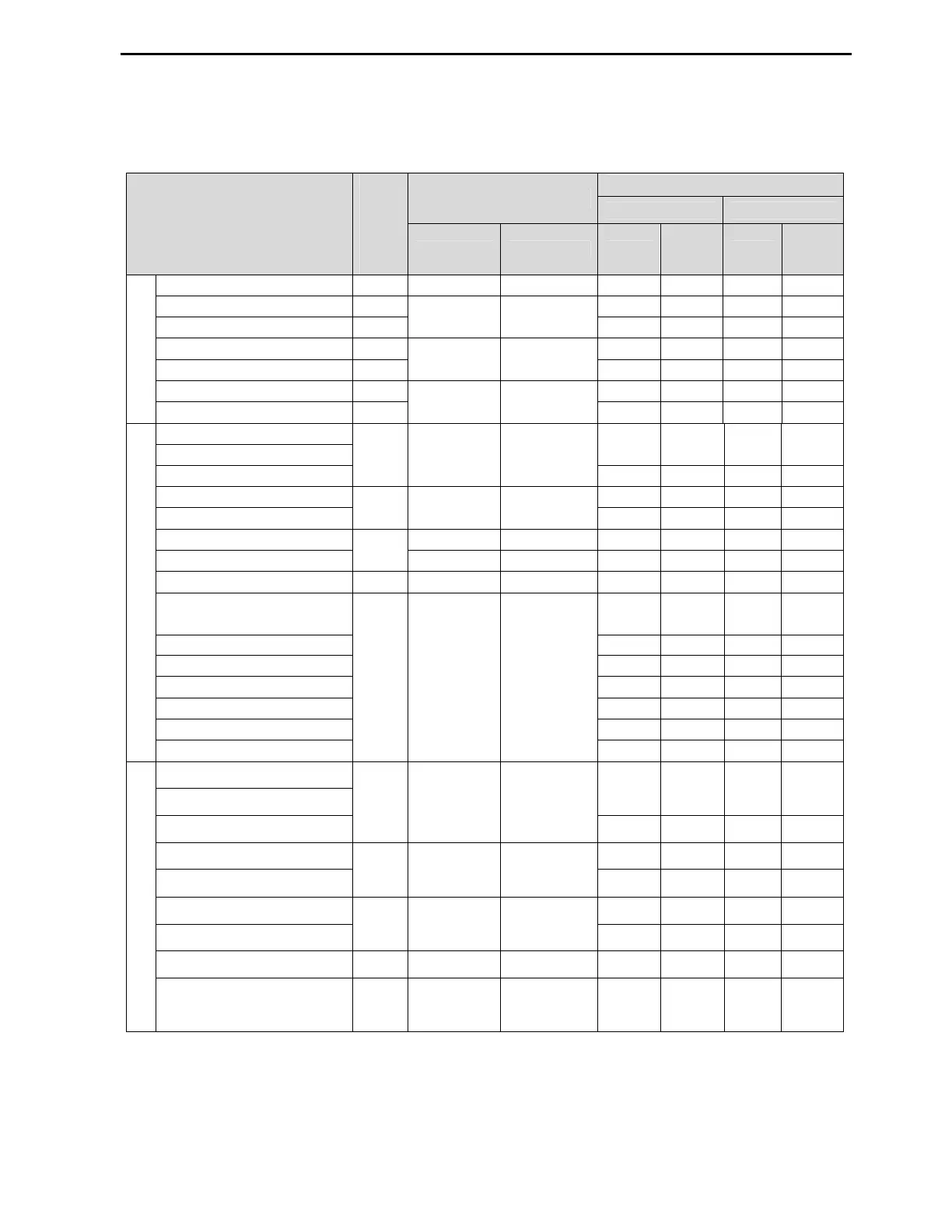

3.2.7 Wire sizes and terminal lugs

Refer to below table for recommended wires sizes, terminal lugs, and screws for VFD power and motor

wiring.

VFD capacity

HP (kW)

Screw

Size Metric

Screw Torque

Wire size

R(L1), S(L2), T(L3)

U, V, W

kgf · cm lb · in mm

2

or

kcmil

mm

2

or

kcmil

230VAC

7.5HP (5.5kW)

M4 7.1 ~ 12.2 6.2~10.6 5.5 10 5.5 10

(7.5kW)

M5

24.5 ~ 31.8 21.2~27.6

8 8 8 8

(11kW)

M5

14

6

14

6

20HP (15kW)

M6

30.6 ~ 38.2 26.6~33.2

22 4 22 4

25HP (18.5kW)

M6 38 2

38 2

(22kW)

M8

61.2 ~ 91.8 53.1~79.7

38 2 38 2

40HP (30kW)

M8 60 1/0 60 1/0

460VAC

(5.5kW)

M4 7.1 ~ 12.2 6.2~10.6

3.5 12 3.5 12

10HP (7.5kW)

15HP (11 kW)

5.5 10

5.5 10

(15kW)

M6 30.6~38.2 26.6~33.2

8 8 8 8

25HP (18.5kW)

14 6 14 6

(22~30kW)

M8

61.2~91.8 53.1~79.7 22 4 22 4

(37~55kW)

67.3~87.5 58.4~75.9 38 2 38 2

100~125HP (75~90kW)

M10 89.7~122.0 77.9~105.9 60 1/0 60 1/0

150~200HP

(110~132kW)

M12

182.4~

215.0

158.3~

186.6

100 4/0 100 4/0

(160kW)

150 300 150 300

(220kW)

200 400 200 400

400HP (280kW)

250 500 250 500

(315kW)

325 700 325 700

600HP (375kW)

2x200 2x400 2x200 2x400

(450kW)

2x250 2x500 2x250 2x500

600VAC

7.5HP (5.5kW)

M4 7.1 ~ 12.2 6.2~10.6

3.5 12 3.5 12

10HP (7.5kW)

15HP (11kW)

5.5 10 5.5 10

20HP (15kW)

M6 30.6~38.2 26.6~33.2

8 8 8 8

25HP (18.5kW)

14 6 14 6

30~40HP (22~30kW)

M8 61.2~91.8 53.1~79.7

22 4 22 4

50~75HP (37~55kW)

38 2 38 2

100~125HP (75~90kW)

M10 89.7~122 77.9~105.9 60 1/0 60 1/0

150~200HP

(110~132kW)

M12 182.4~215 158.3~186.6

100 4/0 100 4/0

Notes: Apply the rated torque to terminal screws providing proper wire connection and protecting the thread from

damage. Loose screws can cause VFD malfunction or damage. Use copper wires with 600V, 75°C ratings. For

10~15HP (7.5~11kW) 230V type VFDs the power and motor terminals are only for use with insulated ring type

connectors.

Loading...

Loading...