1 Operational Manual

lock board for centering. Then, have the mold against board, and press for

clamping on Menu (52) “clamping original return KK LL “, don‘t loose the button in the

clamping internal until the pressure disappeared, then take off the mold-ring.

2.11.2.3 Manual Mold-opening Method:

In Menu (09), press for mold opening on Menu (52) “ mold-closing original return

KK LL “, don‘t loose the button in the mold –opening internal until the tasks is finished.

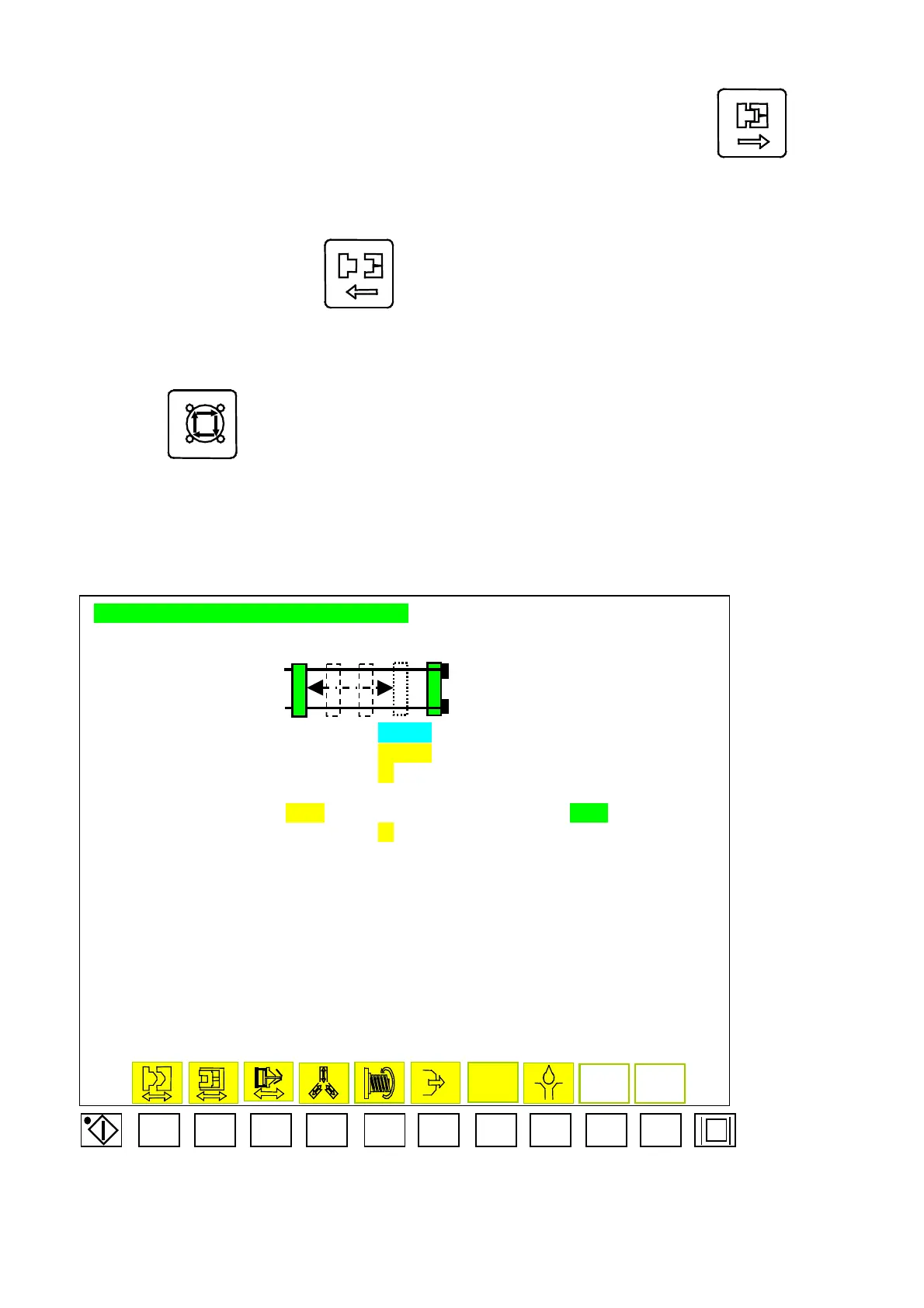

2.11.2.4 Automatic Mold thickness Adjustment

In Menu (09), mold is hung on the mechanism to adjust the counter position and press for

clamping on Menu (52)“ clamping origin return KK CC”. Don‘t loose the button in

the clamping interval until the pressure disappeared, then off the mold-ring.

2.11.3 Second Mold Thickness and Clamping Force Setup

MOLD THICKNESS ADJUSTMENT SETTING

AAAAAAAAAAAAAAAA

BBBBBBBB CCCCCCCC

EXIST MOLD HEIGHT :

PPPP.Pmm

INPUT MOLD THICKNESS : DDDD.Dmm

AUTO. MOLD THICKNESS ADJUSTMENT :

L

CLAMPING FORCE SETTING

EEEEE TONS LOW-PR. CLAMPING POS. AT KKKKKp

AUTO. CLAMPING FORCE SETTING :

M

Menu 09

F1 F2 F3 F4 F5 F6 F7 F8 F9 F10

04/08/13

54

Loading...

Loading...