Mentor ll User Guide 13

Issue Number: 12 www.controltechniques.com

6 Electrical Installation

6.1 Installation Criteria

6.1.1 Safety

The voltages present in the supply cables, the output

cables and terminals, the control power supply wiring

and in certain internal parts of the Drive are capable of

causingsevereelectricshockandmaybelethal.

Electric Shock Risk!

Whenever the Drive has been connected to the main

AC supply system it must be DISCONNECTED and

ISOLATED before any work is done that requires the

removal of a cover. A period of 2 minutes MUST elapse

after isolation to allow the internal capacitors to

discharge fully. Until the discharge period has passed,

dangerous voltages may be present within the module.

Persons supervising and performing electrical

installation or maintenance must be suitably-qualified

and competent in these duties, and should be given the

opportunity to study, and to discuss if necessary, this

Users Guide before work is started.

Ingress Protection

The Drive enclosure conforms to international

enclosure specification IP00 and is suitable for

mounting in NEMA-rated enclosures. It is necessary to

consider the location of and access to the Drive unit

itself in the light of local safety regulations applicable

to the type of installation.

6.1.2 Hazardous areas

The application of variable speed Drives of all types

may invalidate the hazardous area certification

(Apparatus Group and/or Temperature Class) of Ex-

protected (externally-protected) motors. Approval and

certification should be obtained for the complete

installation of motor and Drive. (Refer also to section

5.2.1 Location on page 8)

6.1.3 Earthing (Grounding)

Safety

Drives with isolated heat sinks require that the heat

sink is earthed (grounded) for safety. (Refer also to

section 5.2 Mounting on page 8)

It is recommended that any metal components which

could accidentally become live are solidly earthed

(grounded).

Earth (ground) impedance must conform to the

requirements of local industrial safety regulations and

should be inspected and tested at appropriate and

regular intervals.

6.1.4 Control System Earthing (Grounding)

External AC control circuits, for example, contactors, should be supplied

(from any two phases of the supply) through an isolating transformer

equipped with an earthing (grounding) shield (screen) between the

primary and secondary as shown in Figure 6-2 and Figure 6-3. The

controlwiringshouldbeconnectedtothesameearthing(grounding)

point if possible, or arrangements made to ensure that the earth

(ground) loop impedance complies with an authorized code of practice.

6.1.5 Location

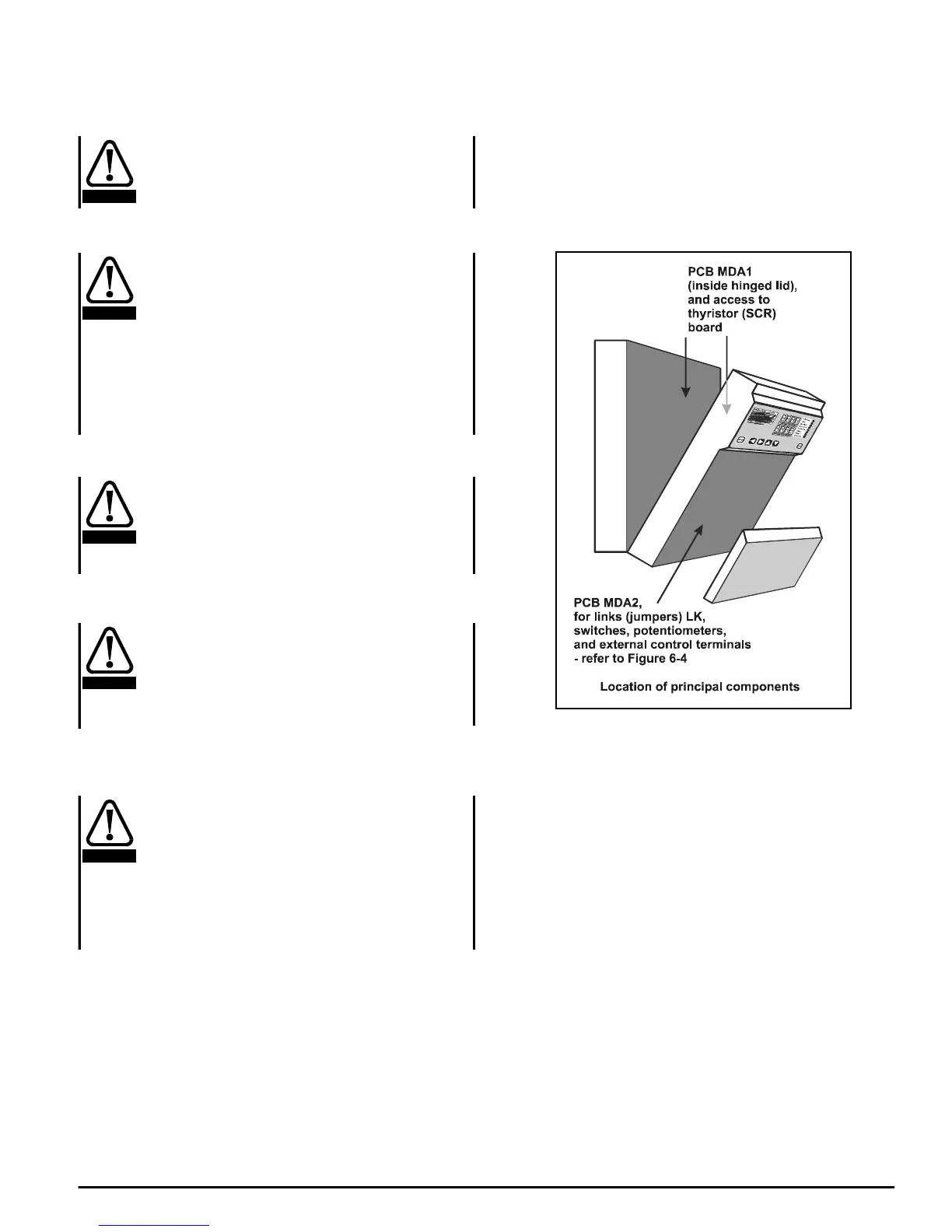

The location of principal components is shown in Figure 6-1.

Figure 6-1

WARNING

WARNING

CAUTION

WARNING

WARNING

Loading...

Loading...