Mentor ll User Guide 3

Issue Number: 12 www.controltechniques.com

3Introduction

Mentor II is the latest family of advanced, fully microprocessor-controlled

DC variable speed industrial Drives. The range of output current is from

25A to 1850A. All sizes share control, monitoring, protection and serial

communications features.

All units are available alternatively in either single-ended or four-

quadrant configuration. Single-ended Drives provide forward run

operation only. Four-quadrant Drives are fully-reversible. Both types

offer comprehensive control of motor speed and/or torque, the four-

quadrant Drives providing full control in both directions of rotation.

Operating parameters are selected and changed either at the keypad or

through the serial communications link (interface). Access for writing or

changing parameter values can be protected by the three-level security

code system.

3.1 DC motor control

The functions of a DC motor which must be controllable for practical use

are the speed, the torque delivered, and the direction of rotation. Speed

is proportional to armature back-emf and inversely proportional to field

flux. Torque is proportional to armature current and field flux. Direction of

rotation is simply a matter of the relative polarities of the armature and

field voltages. It follows that it is necessary to control:

1. The armature voltage; back-emf is a component of armature voltage.

Thus, assuming the field to be constant, control of armature voltage

provides complete control of speed up to the point where the voltage

reaches the maximum value for which the armature is designed.

Armaturecurrentisalsoafunctionofarmaturevoltage,sothat

within the speed range up to maximum voltage, torque is controlled

by voltage also. Provided that the field is fully-excited, the availability

of maximum torque is normally maintained from zero speed up to

armature voltage maximum (base speed).

2. The field voltage; this determines the field current and, in

consequence, field flux. If field voltage can be varied independently

of the armature voltage, speed can be increased at full power (full

armature voltage) beyond the point where the applied armature

voltage and current are at maximum. Since torque is directly

proportional to field flux, maximum torque is reduced if speed is

increased by weakening the field.

Basically, therefore, a variable speed DC Drive is a means of controlling

the voltage applied to the armature of the motor, and thus the current

delivered to the motor. The Drive may be equipped with means for

control of the field if speeds higher than base speed are required.

Separatecontrolofthefieldwithintheoperatingrangeuptobasespeed

can be exploited also, to obtain extended control of speed and torque for

more-complex motor applications. If a suitable feedback is available,

position control becomes possible.

3.2 Principles of the variable speed drive

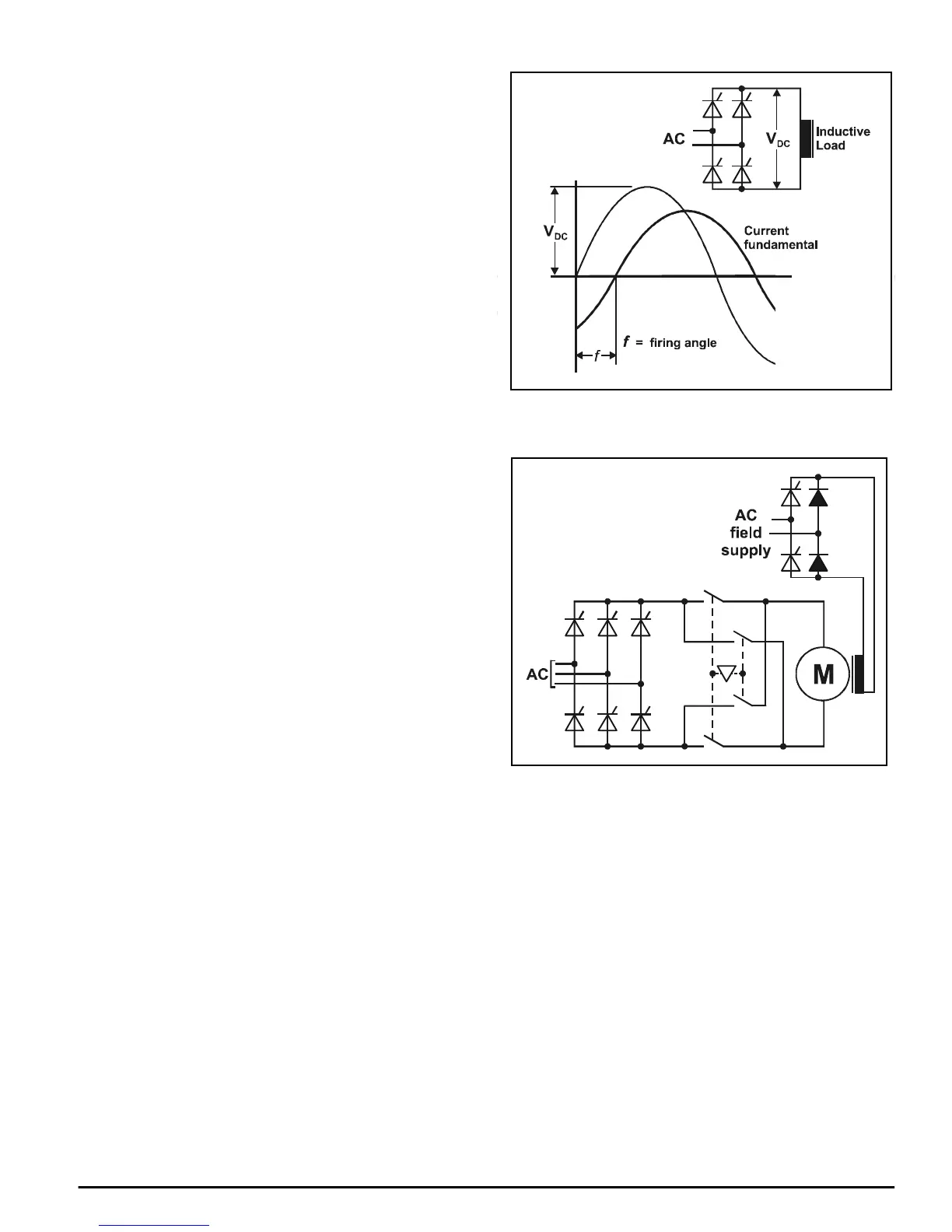

A single phase voltage applied to a fully-controlled thyristor (SCR) bridge

and a resistive load produces an intermittent flow of current which is

started by the firing of the thyristor (SCR), and stopped as a result of the

supply voltage passing through zero at the end of each half cycle.

Maximum voltage is delivered when the firing angle is fully advanced,

that is, when f in Figure 3-1 becomes zero. Retarding the firing angle

reduces the current output. When the load is inductive, such as a motor,

or the firing angle is sufficiently advanced, current becomes continuous .

The fundamental of the current characteristically lags behind the voltage

due partly to the inductive nature of the load and partly due to firing

angle delay.

Figure 3-1 Behavior of a single-phase fully-controlled thyristor

rectifier (SCR) supplying a highly-inductive load

Figure 3-2 Typical arrangement for reversing a “single-ended” DC

drive using an interlocked pair of contactors in the armature circuit

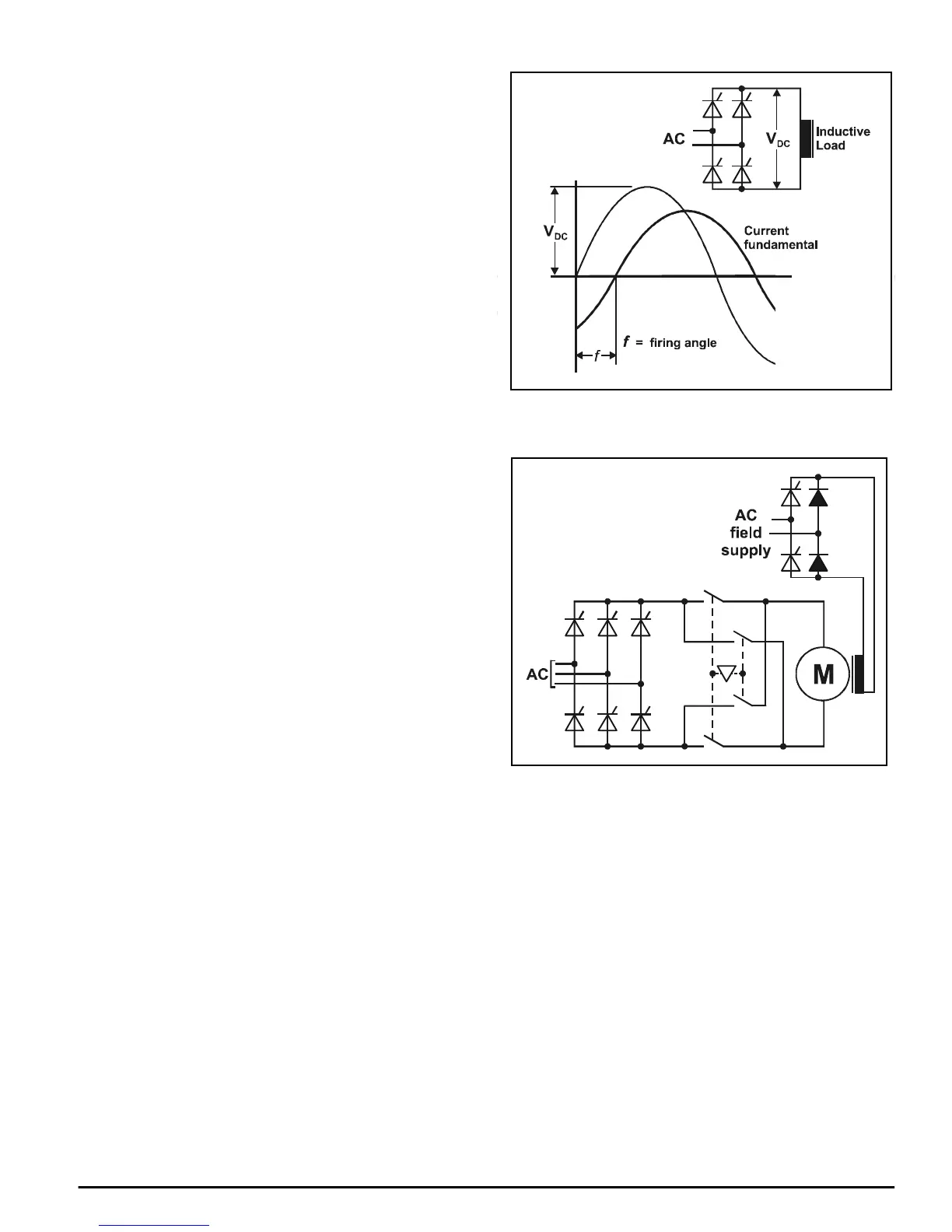

3.3 Reversing

Reversal of rotation is done in one of two ways, dependent on the type of

Drive bridge configuration. The simplest fully-controllable arrangement

of thyristor (SCR) bridge configuration to operate from a 3-phase AC

supply is a full-wave bridge but this is not capable of reversing the output

polarity. This type, which is called single-quadrant or single-ended,

requires a means of switching the motor terminals externally as shown in

Figure 3-2 if reversing is required. For some applications this simple

system is an adequate practical solution.

If, however, the motor application is such that it demands complete

control of motor operation in both directions, with the ability to reverse

motor torque rapidly and frequently, two anti-parallel bridges must be

used, Figure 3-3. This configuration provides full control of forward and

reverse Drive and forward and reverse braking without the need for

reversing contactors, and is called four-quadrant, Figure 3-4.

If braking is required with a single-ended Drive, an external circuit has to

be provided, Figure 3-5 (dynamic braking). In this case, deceleration is

neither controlled nor linear.

Loading...

Loading...