Mentor ll User Guide 55

Issue Number: 12 www.controltechniques.com

Menu 06: Field Control

The Mentor II is equipped with field control as part of the on-board

software. If a motor is being used with an uncontrolled (fixed) field

supply, this menu does not apply.

Provision is made for programming two selectable values of maximum

field current. Further, the lower value of maximum field current can be

controlled by a programmable timer so that, when the Drive is not

running, the field can be switched automatically to economy mode.

The resulting field current demand is summed algebraically with the field

current feedback to produce a current error which is the input to the field

current loop. The output of the field current loop is the firing angle,

subject to the front endstop limit.

The field current can alternatively be controlled directly by either of the

maximum field parameters 06.08 and 06.09 via a programmable input or

by application software, and there is a facility for direct control of the

firing angle, useful for diagnosis.

Field current demand is the output of the back-emf voltage loop, subject

to programmed maximum and minimum field current values. The voltage

loop compares the calculated back-emf value with a programmed set

point which is used as factor in determining field current demand.

The voltage loop output, and consequently the field current demand, is

maximum when the calculated back-emf is less than the setpoint value.

When the calculated value exceeds the set point value (at base speed)

the voltage loop reduces the field current demand to regulate the

calculated back-emf to the set point value.

Alternatively, the user may wish not to use the voltage loop, but to enter

a current demand directly. The user can set two maximum field current

parameter values. In this mode, the value of the back-emf set point

should be set to maximum, such that the voltage loop always demands

maximum field current. The current demand is then the selected

maximum field current parameter.

The calculated motor back emf based on armature voltage minus IR

compensation value 2, 06.05. Feedback to the emf loop in spillover

mode.

The current demand from the emf loop, subject to the limits of 06.08,

06.09 and 06.10.

Feedback to the field current loop

Scaling 06.04 = 1000 corresponds to fully phased forward

The value resulting from the application of 06.06 to the speed error

integral input.

A programmable factor used for calculation of the armature IR-drop as

correction to measured armature voltage, to allow the back emf to be

computed.

If 06.20 =0:

If 06.20 =1:

Example of setting of 06.06

Armature voltage = 400V

Armature current = 200A

Armature resistance = 0.1Ω

I x R =20V

For a M210 with 200A armature current

03.08 = 635 units

so,

06.07 = 380V

The programmable value of the armature back emf in volts, at which the

field begins to weaken. Defined as the voltage at which base speed is

reached.

Programmable value of the maximum current demand of the emf loop. If

the field control is to be used in current mode, this parameter would

become the current reference of the field control loop, and the back emf

set point should normally be set to maximum to prevent spillover

occurring; alternatively, if motor overvoltage protection by spillover is

required, the back emf set point should be set to maximum armature

voltage.

Alternative to 06.08, for use as an economy setting. Refer to 06.12,

06.14 and 06.15.

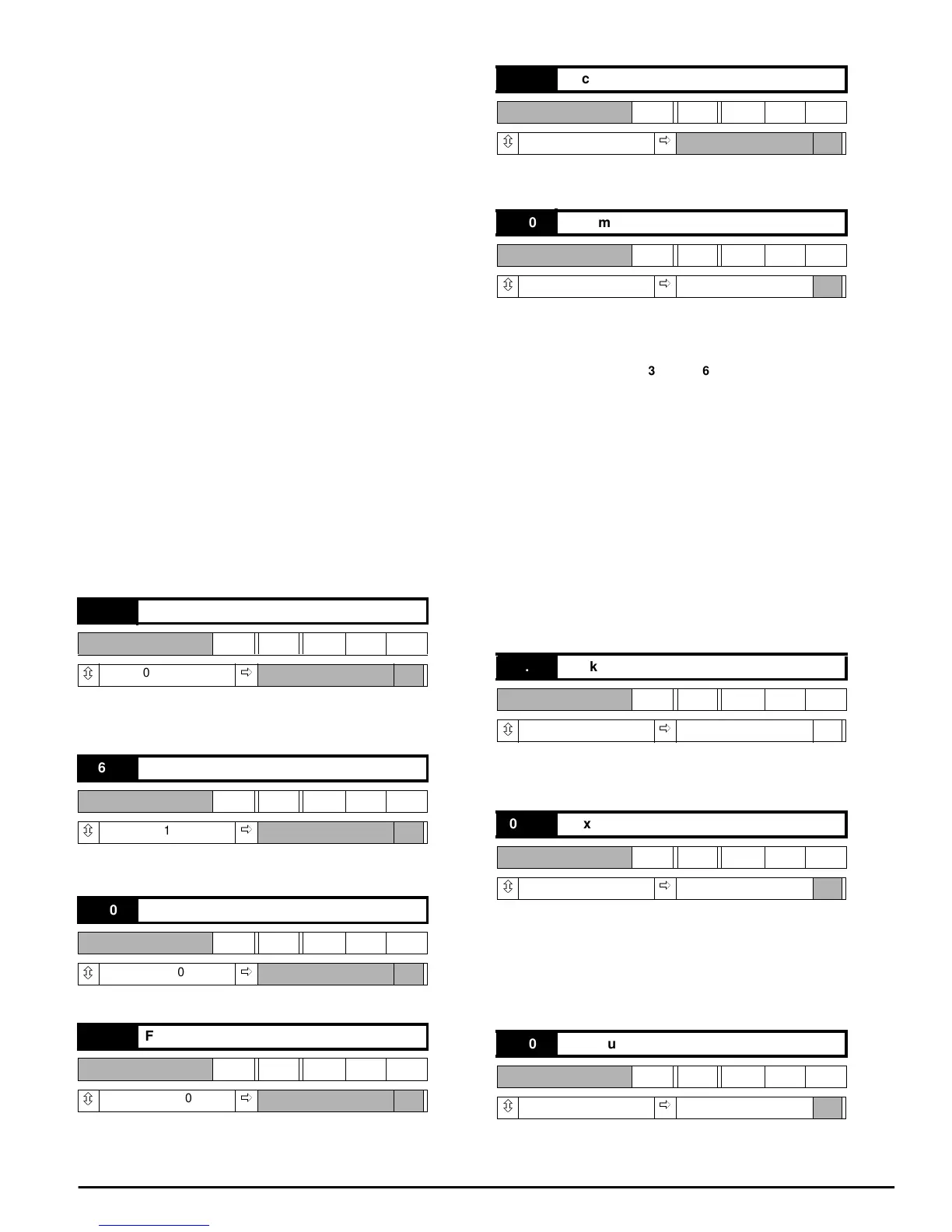

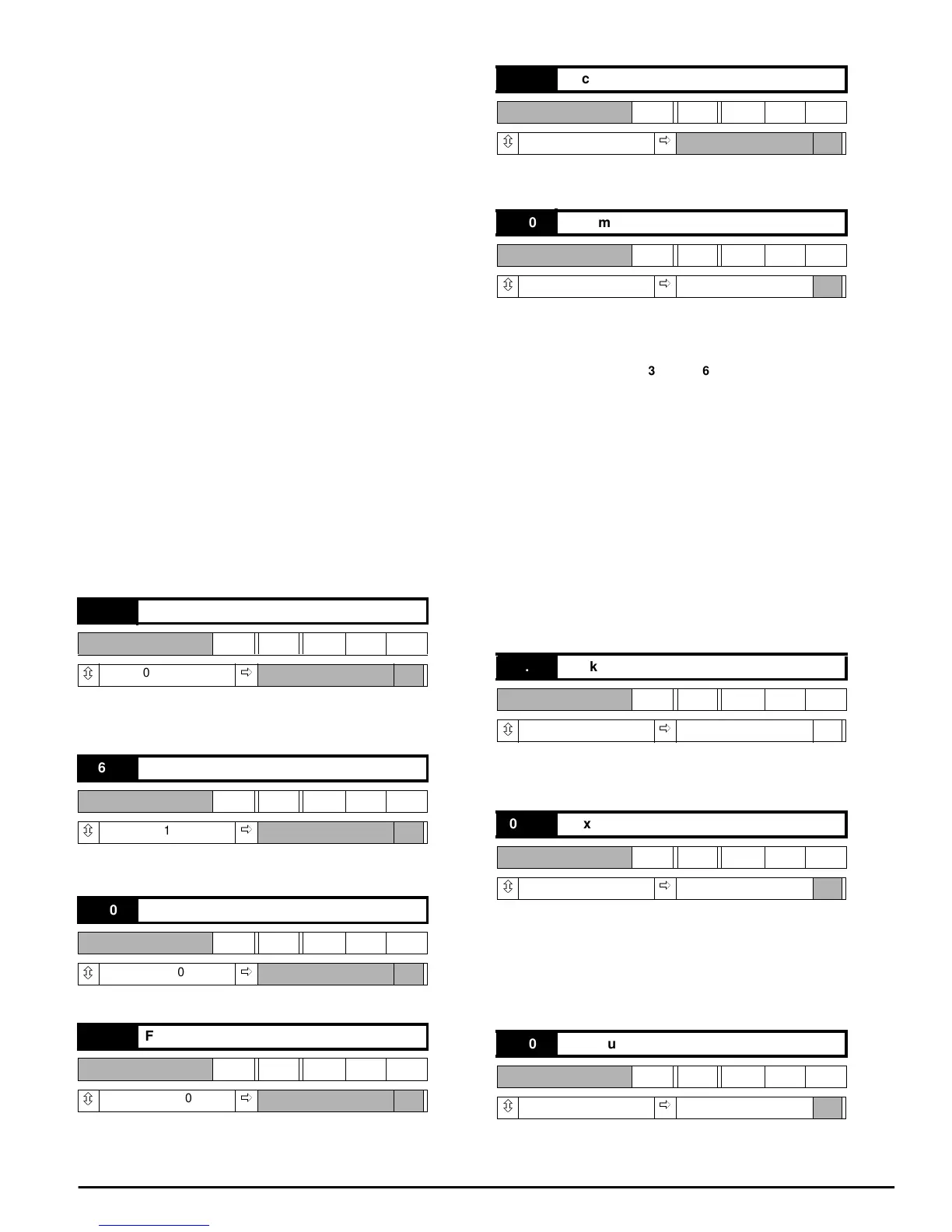

06.01 Back emf

RO Uni

ô

0 ~ 1000

ð

06.02 Field current demand

RO Uni

ô

0 ~ 1000

ð

06.03 Field current feedback

RO Uni

ô

0 ~ 1000

ð

06.04 Firing angle

RO Uni

ô

261 ~ 1000

ð

06.05 IR compensation 2 output

RO Bi

ô

±1000

ð

06.06 IR compensation 2

RW Uni

ô

0~255

ð

000

06.07 Back emf set point

RW Uni

ô

0 ~ 1000

ð

+1000 V

06.08 Maximum field current 1

RW Uni

ô

0 ~ 1000

ð

+1000

06.09 Maximum field current 2

RW Uni

ô

0 ~ 1000

ð

+500

06.05

03.08()06.06()×

2048

----------------------------------------------

=

06.05

04.02()06.06()×

2048

----------------------------------------------

=

06.06

20 2048×

635

--------------------------

64units==

Loading...

Loading...