44 Mentor ll User Guide

www.controltechniques.com Issue Number: 12

Menu 03: Feedback Selection and Speed Loop

The principal inputs are the post-ramp reference 02.01 and the hard

speed reference 03.18. The post-ramp reference can be summed with or

replaced by the hard speed reference. The speed reference can,

alternatively, be the hard speed reference alone. The selected input can

be modified by the addition of an offset. The result of this summation is

the final speed demand (03.01) which is added algebraically to the

speed feedback to become the speed error (03.06). The speed error is

finally processed by the PID function to become the speed loop output.

Speed feedback is derived from one of three possible sources, encoder

(pulse tach.), tachogenerator (tachometer) or armature voltage.

Whichever source is selected becomes the speed feedback (03.02). If

the armature voltage is selected it is first summed with the IR

compensation (03.05), which is derived from the integral function of the

speed error and the IR compensation factor is then either added to or

subtracted from the scaled armature voltage feedback according to

whether IR compensation or IR droop is selected.

The armature voltage feedback is passed to a comparator to provide a

voltage clamp, used internally to prevent armature overvoltage.

Parameter 03.15 becomes the clamp level.

The speed feedback value is used for two further purposes to supply a

speed indication in rpm, and to indicate zero speed.

Monitors the value of the speed reference after it has bypassed or been

modified by the ramps and/or by the hard speed reference (03.18)and

speed offset fine (03.22). It is the speed reference which is presented to

the speed control loop of the Drive via the speed summation point.

Monitors the value of the speed feedback, derived from one of the

following three sources encoder (pulse tach.), tachogenerator

(tachometer), or armature voltage. The selection is controlled by 03.12

and 03.13. The value is used for the closed-loop speed control of the

motor. Scaling of the encoder (pulse tach.) signal is set by 03.14, and of

the armature voltage feedback is controlled by the setting of maximum

armature voltage 03.15. A potentiometer is provided for scaling the

tachogenerator (tachometer) feedback signal. The speed feedback

03.02 is summed with the final speed demand 03.01 at the speed loop

summation point.

Scaled value of motor speed feedback for external information.

The result of selected value of IR compensation 03.17 acting on the

speed loop integral output.

The result of the summation of the final speed demand and the speed

feedback, after filtering.

Output of the PID speed loop which becomes current demand (menu

04).

The integrated value of the speed error 03.06, used as input to the IR

compensation calculation when using armature voltage feedback (AVF).

The factor by which the speed error is multiplied to produce the

correction term.

Increasing this value increases both the system damping and the

transient speed response, and if made too high for a given load the

system will become unstable. The optimum setting is the highest value

possible before instability starts to occur. Optimum speed loop

performance is achieved by judicious combination of all three gains of

the PID algorithm. See 03.28 to increase the speed loop proportional

gain by a factor of 4.

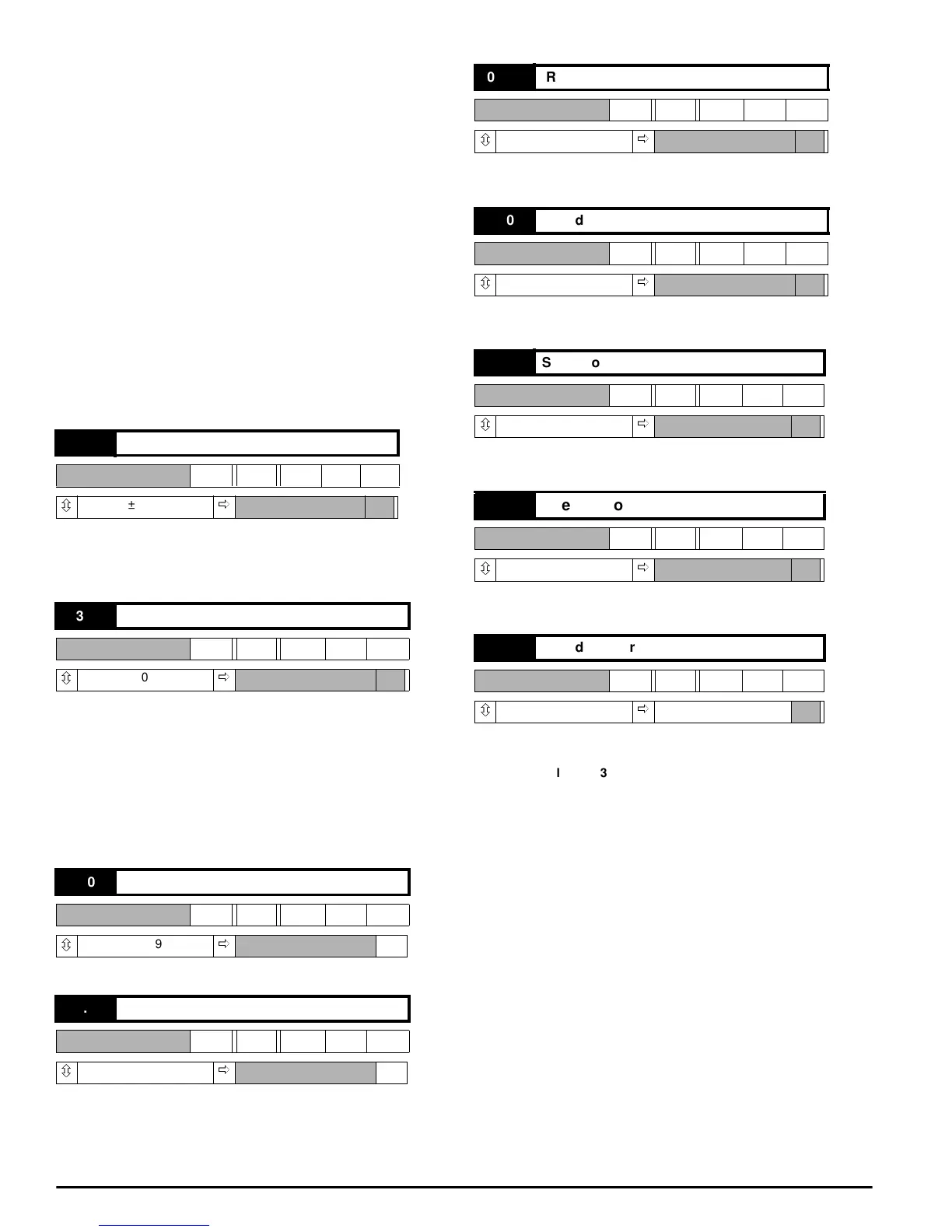

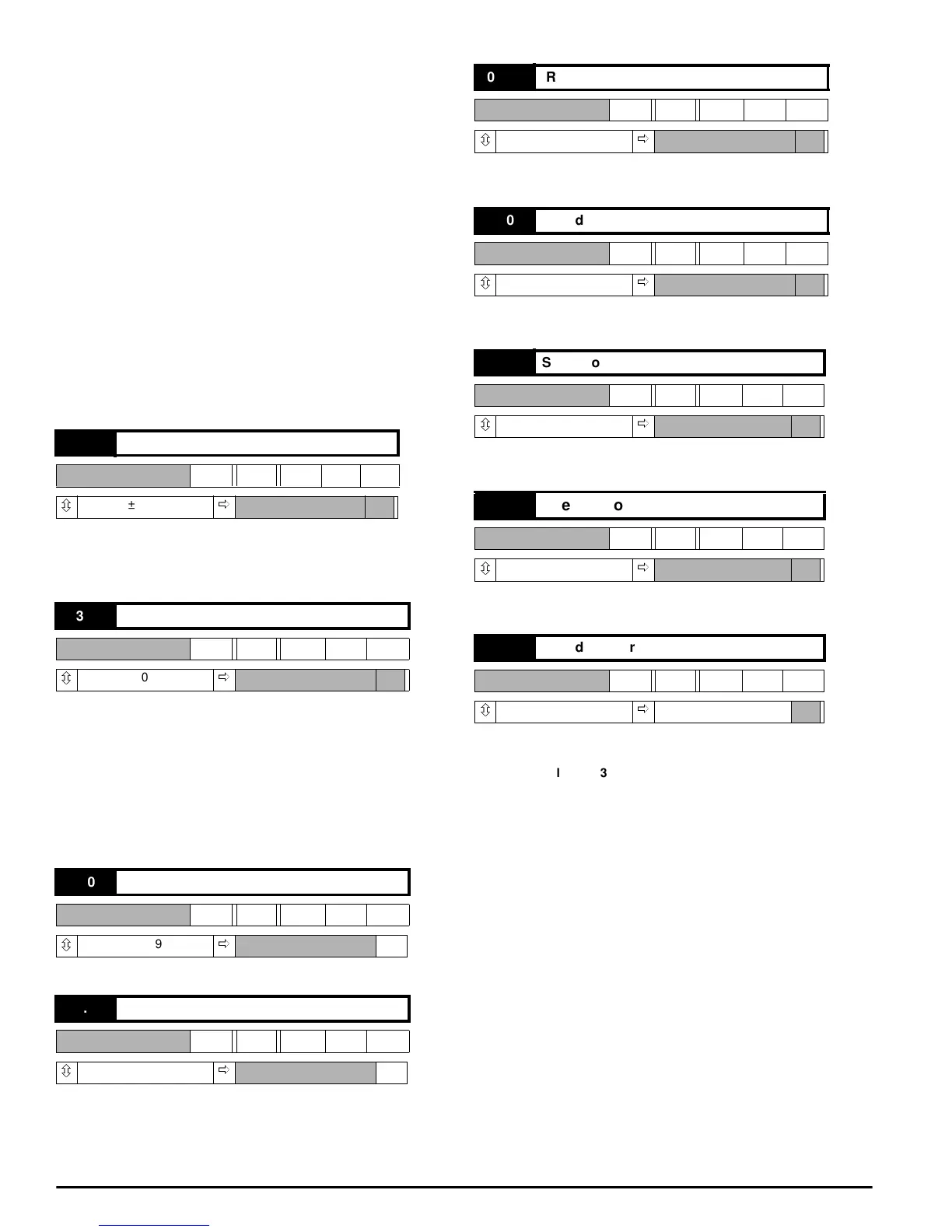

03.01 Final speed demand

RO Bi

ô

±1000

ð

03.02 Speed feedback

RO Bi

ô

±1000

ð

03.03 Speed feedback (rpm)

RO Bi

ô

±1999

ð

rpm

03.04 Armature voltage

RO Bi

ô

±1000

ð

V

03.05 IR Compensation output

RO Bi

ô

±1000

ð

03.06 Speed error

RO Bi

ô

±1000

ð

03.07 Speed loop output

RO Bi

ô

±1000

ð

03.08 Speed error integral

RO Bi

ô

±1000

ð

03.09 Speed loop proportional gain

RW Uni

ô

0~255

ð

080

Factor

ValueOf03.09

8

----------------------------------------

=

Loading...

Loading...