95XF series Inspection and adjustment

EXPLANATORY NOTES ON THE MAINTENANCE ACTIVITIES

3-57

Note:

There are 2 split pin holes in the axle

journal. Select the split pin hole where the

hub nut needs to be turned back least.

8. Check the wheel bearing play. Check the

bearings for wear if the wheel bearing play

is still too large after adjustment.

9. Fit the hub cap. Tighten the hub cap to the

specified t orque using the special tool (DAF

no. 1329498). See “Technical data”.

10. Adjust the brakes.

TRAILING AXLE 09N220

Checking the wheel bearing play

1. To make sure that the inspection of the

wheel bearing play is r eliable, use the

special tool (DAF no. 0535595).

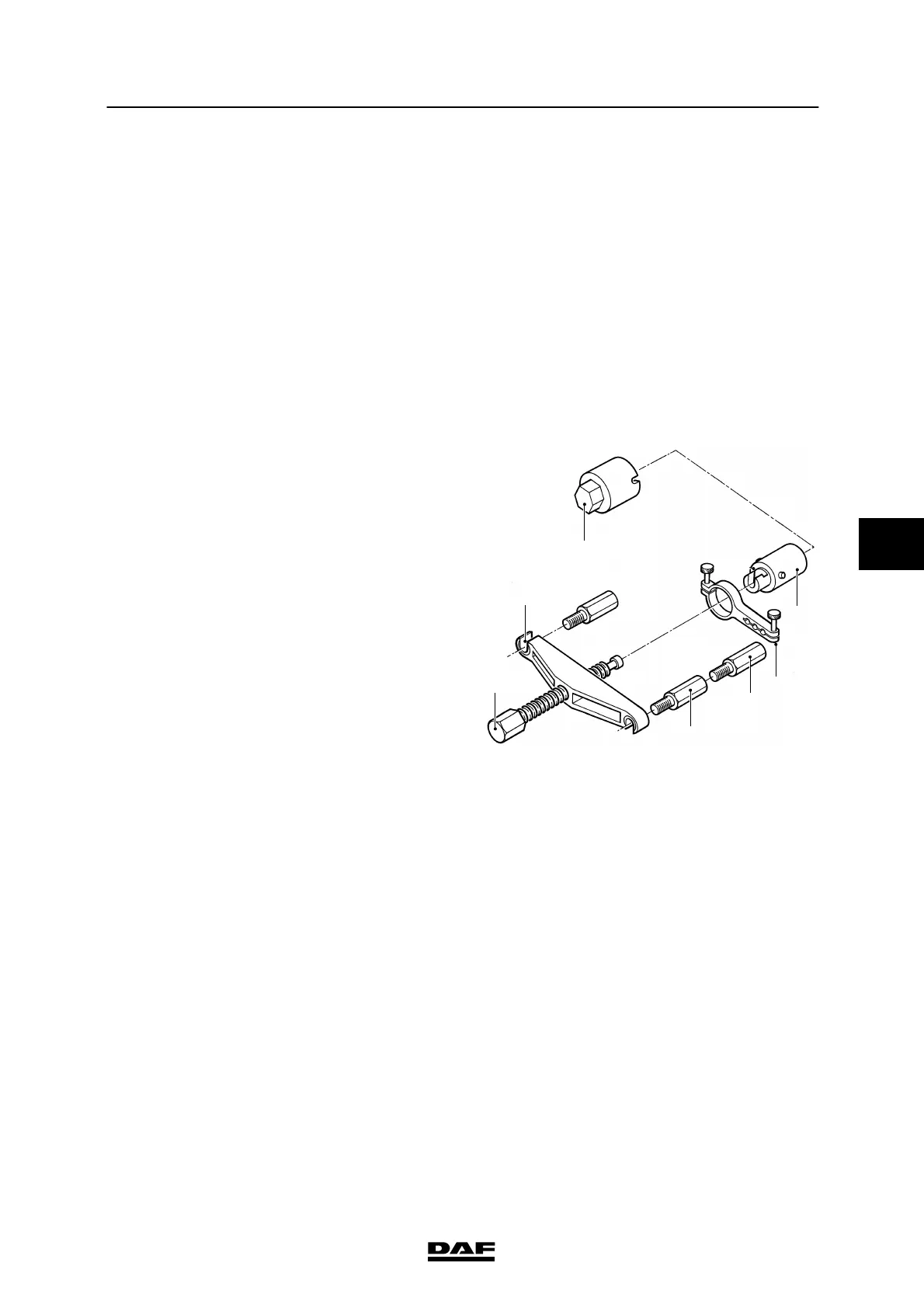

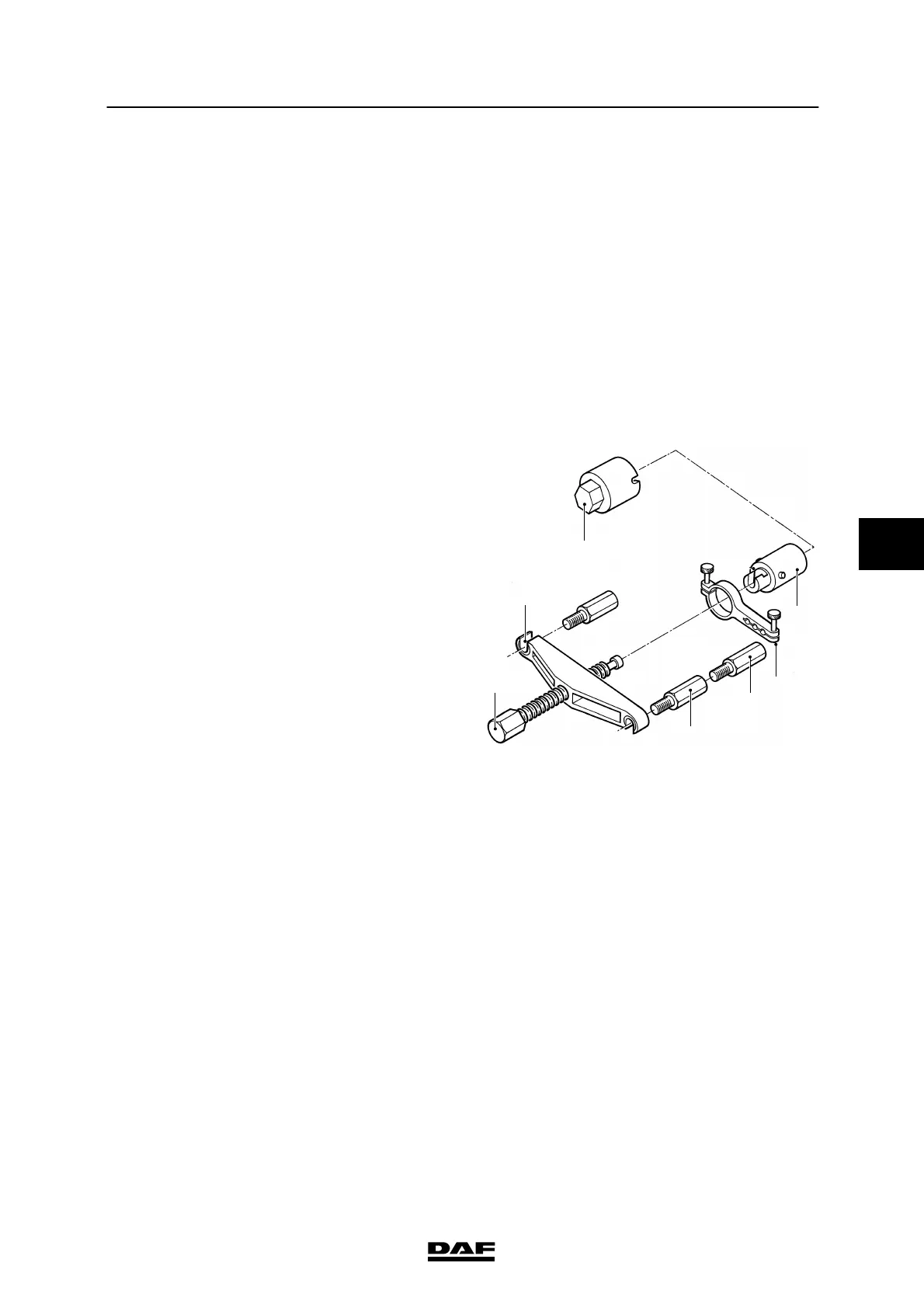

The s pecial tool consists of:

1. extensions

2. central nut

3. dial gauge holder

4. threaded spindle

5. bridge

6. socket wrench

7. additional extension pieces

2. Remove the hub cap.

3. Remove two opposite wheel nuts.

4. Fit the extensions (1) onto the vacant wheel

studs.

5. Place the dial gauge holder (3) on the

central nut (2).

S7 00 131

1

7

6

4

5

3

2

5

200424

Loading...

Loading...