EXPLANATORY NOTES ON THE MAINTENANCE ACTIVITIES

Inspection and adjustment 95XF series

3-58

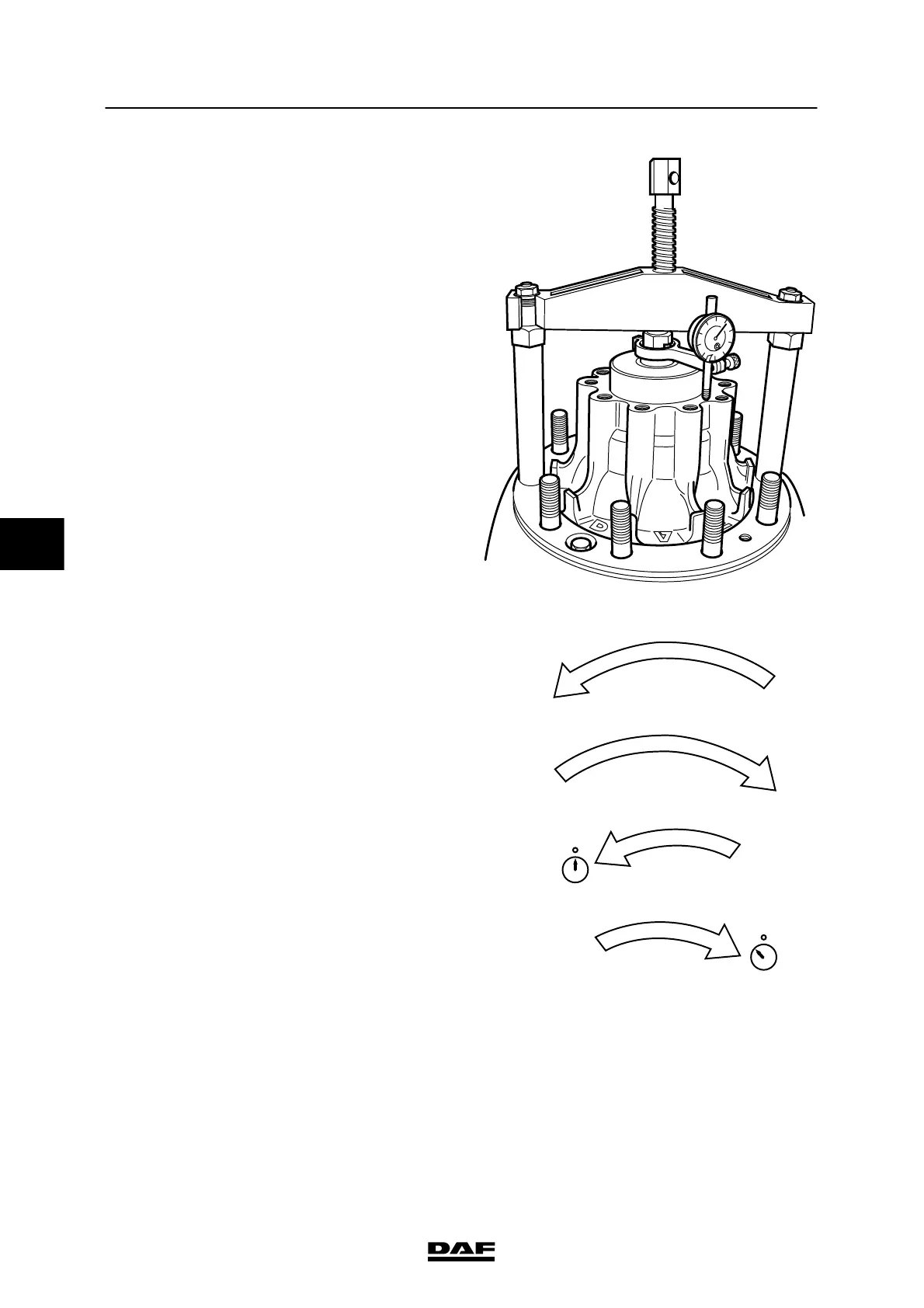

6. Fit the c entral nut (2) to the axle journal

using t he socket wrench (6).

7. Place the dial gauge in the dial gauge

holder (3) so that the stylus abuts the hub.

Make s ure that the stylus of the dial gauge

does not enter a t hreaded hole of the hub,

because t he stylus might break off when the

wheel is turned.

8. Position the bridge (5) on the extensions (1)

so that the end of the spindle fits into the

recess of the central nut (2). Tighten the

bridge with the nuts.

9. Place a torque wrench on the hexagon

head of the s pindle (4).

Press the hub firmly onto the axle journal by

screwing t he spindle in, until a tightening

torque of 40 Nm is reached.

A800149

10. Withdraw the hub by unscrewing the spindle

until a tightening torque of 40 Nm is

reached.

11. Press the hub on to the axle journal by

screwing t he spindle in until a tightening

torque of 15 Nm is reached, and set the dial

gauge to “O”.

12. Withdraw the hub by unscrewing the spindle

until a tightening torque of 15 Nm is

reached. Take the reading from the dial

gauge and compare this v alue with the

specified v alue, see “Technical data”.

If the reading falls outside the tolerance

range, the wheel bearing play should be

re-adjusted.

13. Remove t he special tool.

14. If the lock nut has been removed, the lock

plate s hould be replaced. Tighten the lock

nut to the specified tightening torque. See

“Technical data”.

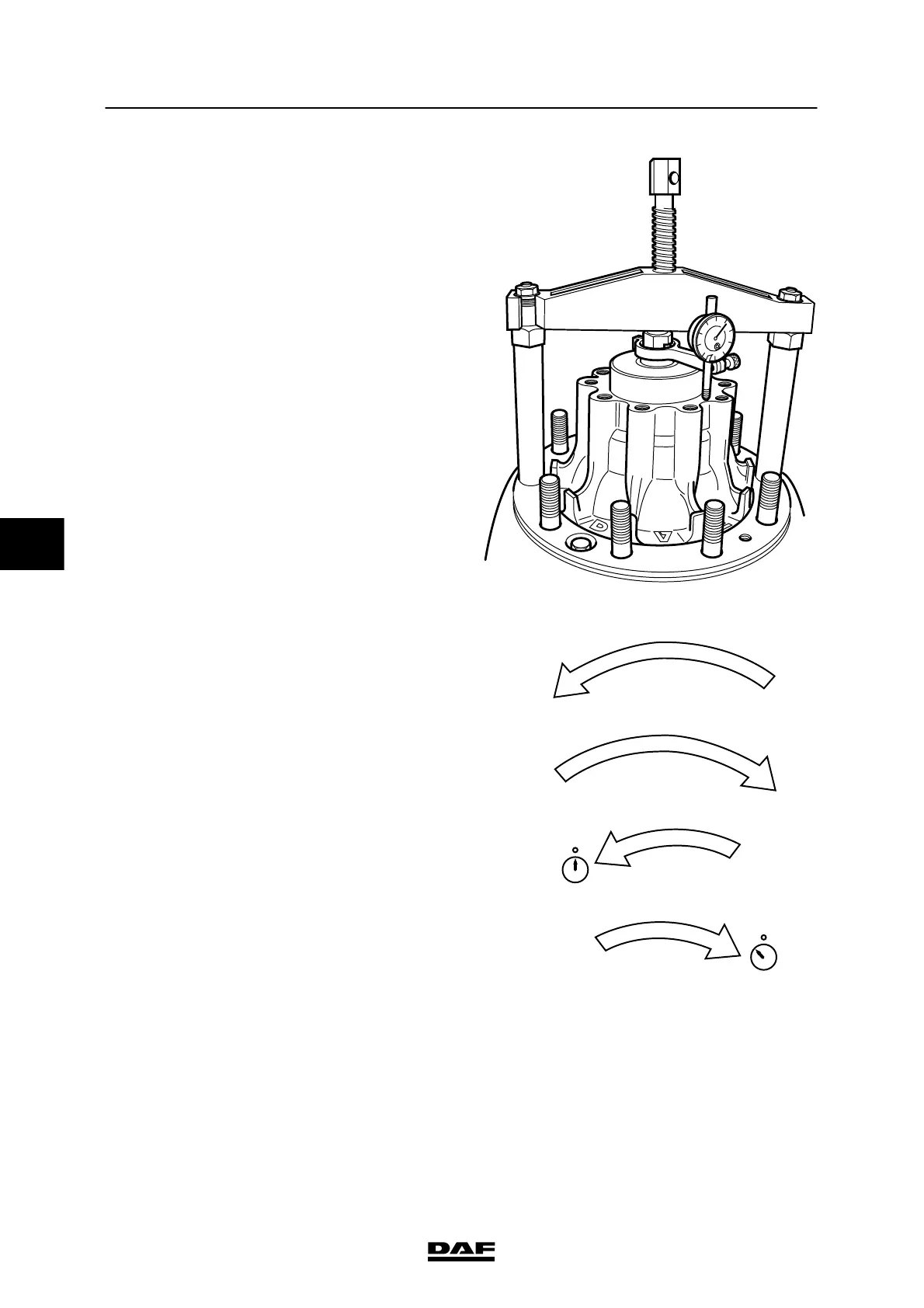

40Nm

40Nm

15Nm

15Nm

(1)

(2)

(3)

(4)

A800150

5

200424

Loading...

Loading...