95XF series Inspection and adjustment

EXPLANATORY NOTES ON THE MAINTENANCE ACTIVITIES

3-59

15. Apply some grease to the outside of the

bearing cage.

16. Apply silicone sealant to the hub cap.

17. Install the spring assembly.

18. Tighten the two wheel nuts to the specified

torque. Mark these t wo nuts and tighten

them after 100 km.

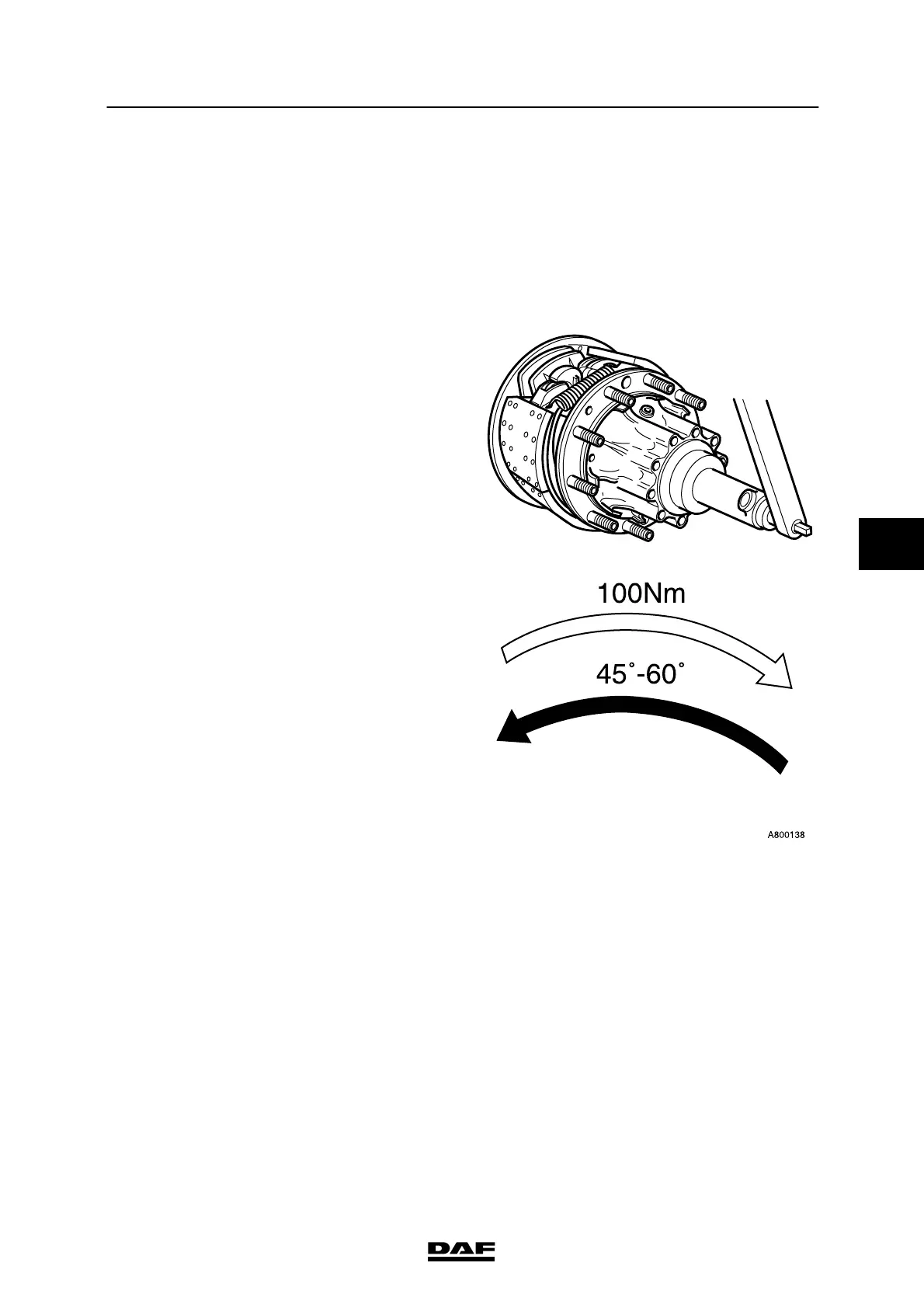

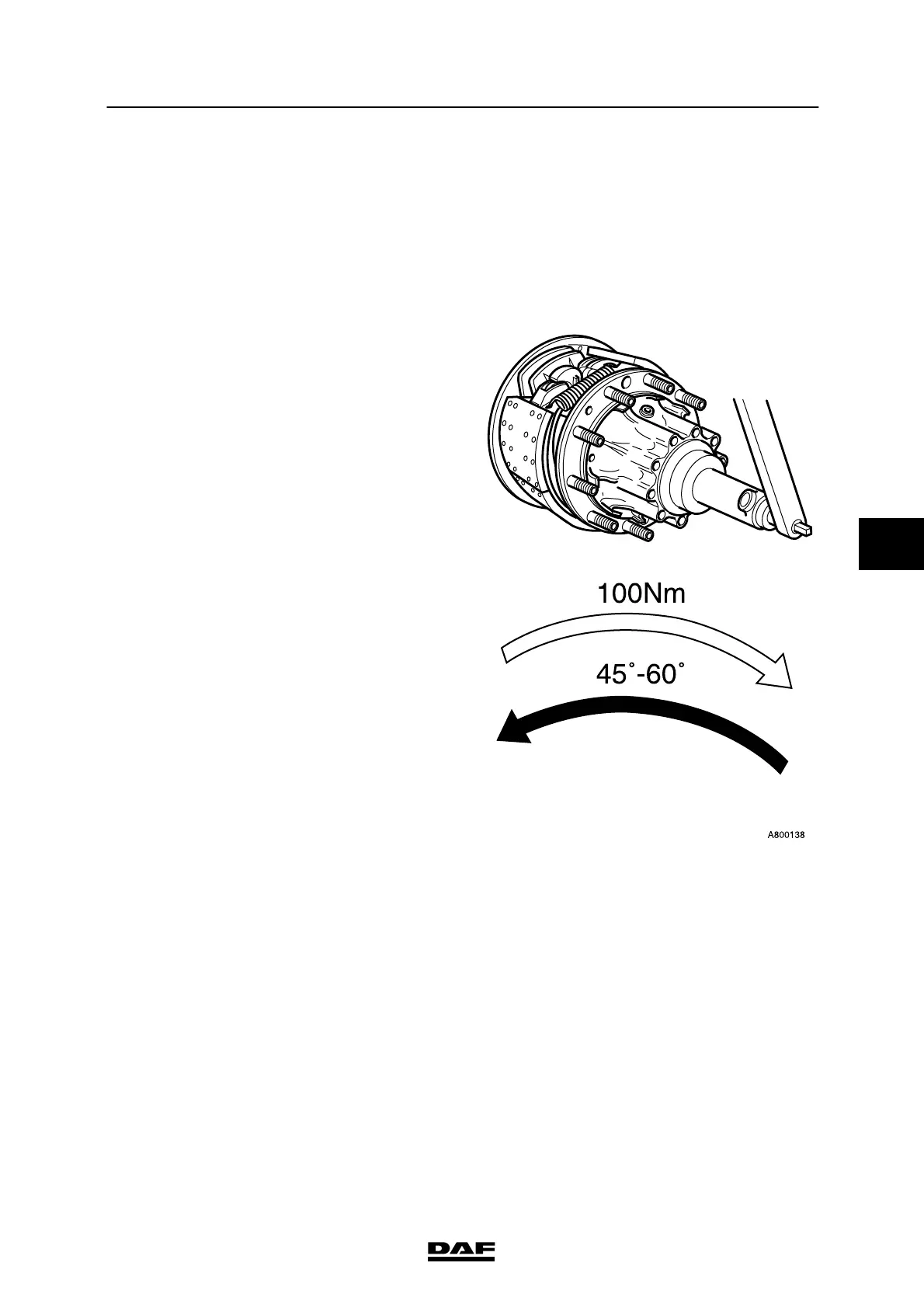

Adjusting the wheel bearing play

1. Use a special tool (DAF no. 0535648) to

remove t he lock nut from the axle journal.

2. Remove the lock plate and the circlip from

the axle journal.

3. Loosen the hub nut one turn.

4. Tighten the adjusting nut to a tightening

torque of 100 Nm using a torque wrench,

while turning the hub.

5. The specified wheel bearing play is

achieved by turning t he hub nut

counter-clockwise between 45 ° and 60° .

The c orrect angle is the one that allows the

circlip to be fitted. If necessary, turn the

circlip around, changing the hole pattern.

6. Fit the c irclip so that the circlip lip falls into

the k ey groove of the axle journal and the

dowel pin of the axle nut falls into one of the

holes of the circlip.

7. Fit the lock nut. Tighten the lock nut to the

specified t orque using the special tool (DAF

no. 0535648). See “Technical data”.

8. Install the spring assembly.

A800148

5

200424

Loading...

Loading...