parameter 4-14 Motor Speed High Limit [Hz]. However, in

practice, it is limited by this setting.

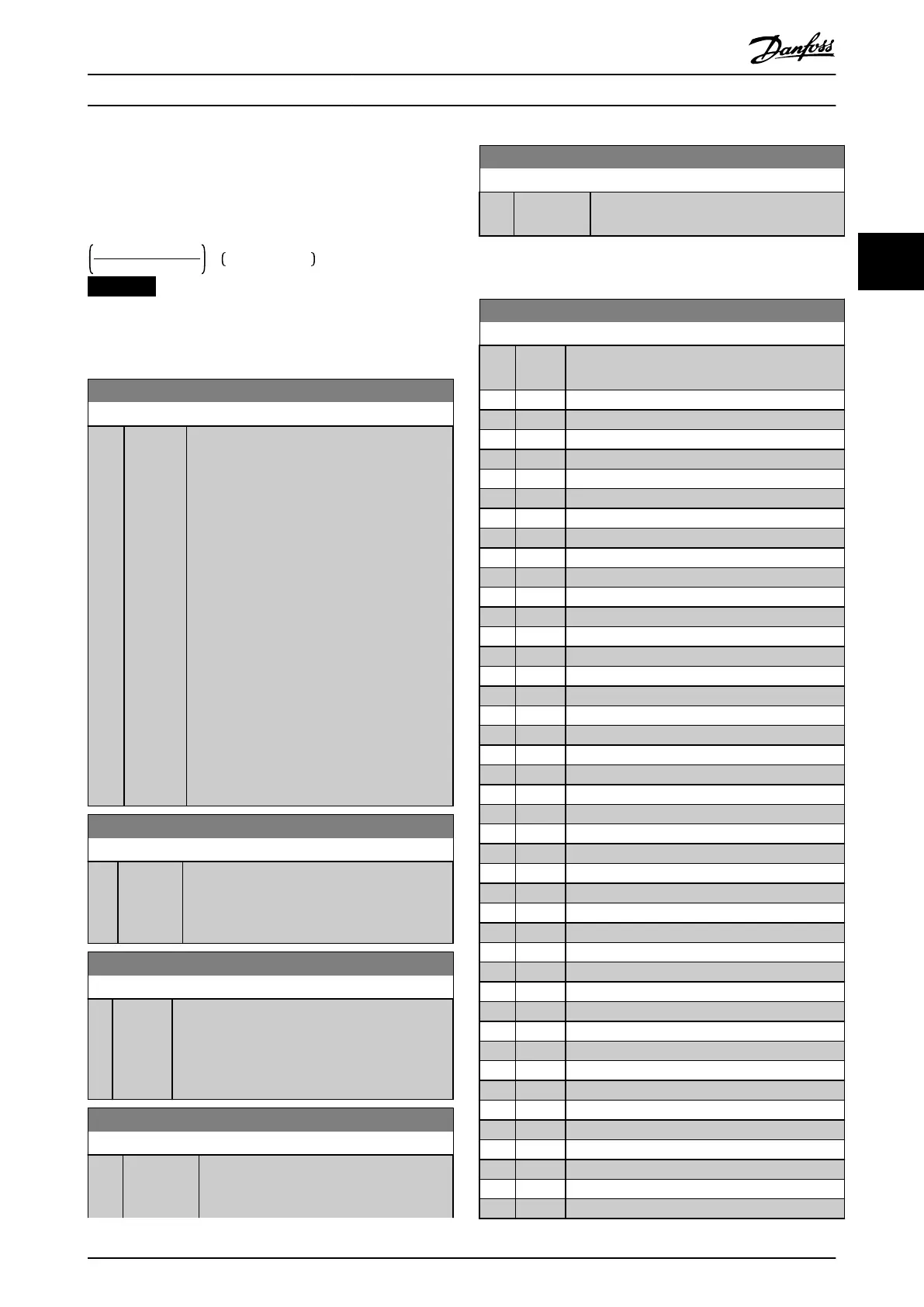

The proportional band (error causing output to change

from 0–100%) can be calculated with the formula:

1

ProportionalGain

× MaxReference

NOTICE

Set the value for parameter 3-03 Maximum Reference

before setting the values for the PID controller in

parameter group 20-9* PID Controller.

21-22 Ext. 1 Integral Time

Range: Function:

20

s*

[0.01 -

10000 s]

Over time, the integrator accumulates a contri-

bution to the output from the PID controller as

long as there is a deviation between the

reference/setpoint and feedback signals. The

contribution is proportional to the size of the

deviation. This ensures that the deviation

(error) approaches 0.

Quick response on any deviation is obtained

when the integral time is set to a low value.

Setting it too low, however, may cause the

control to become unstable.

The value set is the time needed for the

integrator to add the same contribution as the

proportional for a certain deviation.

If the value is set to 10000, the controller acts

as a pure proportional controller with a P-band

based on the value set in parameter 20-93 PID

Proportional Gain. When no deviation is

present, the output from the proportional

controller is 0.

21-23 Ext. 1 Dierentation Time

Range: Function:

0 s* [0 - 10 s] The dierentiator does not react to a constant

error. It only provides a gain when the feedback

changes. The quicker the feedback changes, the

stronger the gain from the dierentiator.

21-24 Ext. 1 Dif. Gain Limit

Range: Function:

5* [1 - 50 ] Set a limit for the dierentiator gain (DG). The DG

increases if there are fast changes. Limit the DG to

obtain a pure dierentiator gain when changes

are slow and a constant dierentiator gain when

quick changes occur.

21-26 Ext. 1 On Reference Bandwidth

Range: Function:

5 %* [0 - 200 %] Enter the on-reference bandwidth. When the

PID control error (the dierence between the

reference and the feedback) is less than the

21-26 Ext. 1 On Reference Bandwidth

Range: Function:

value of this parameter, the on-reference

status bit is high.

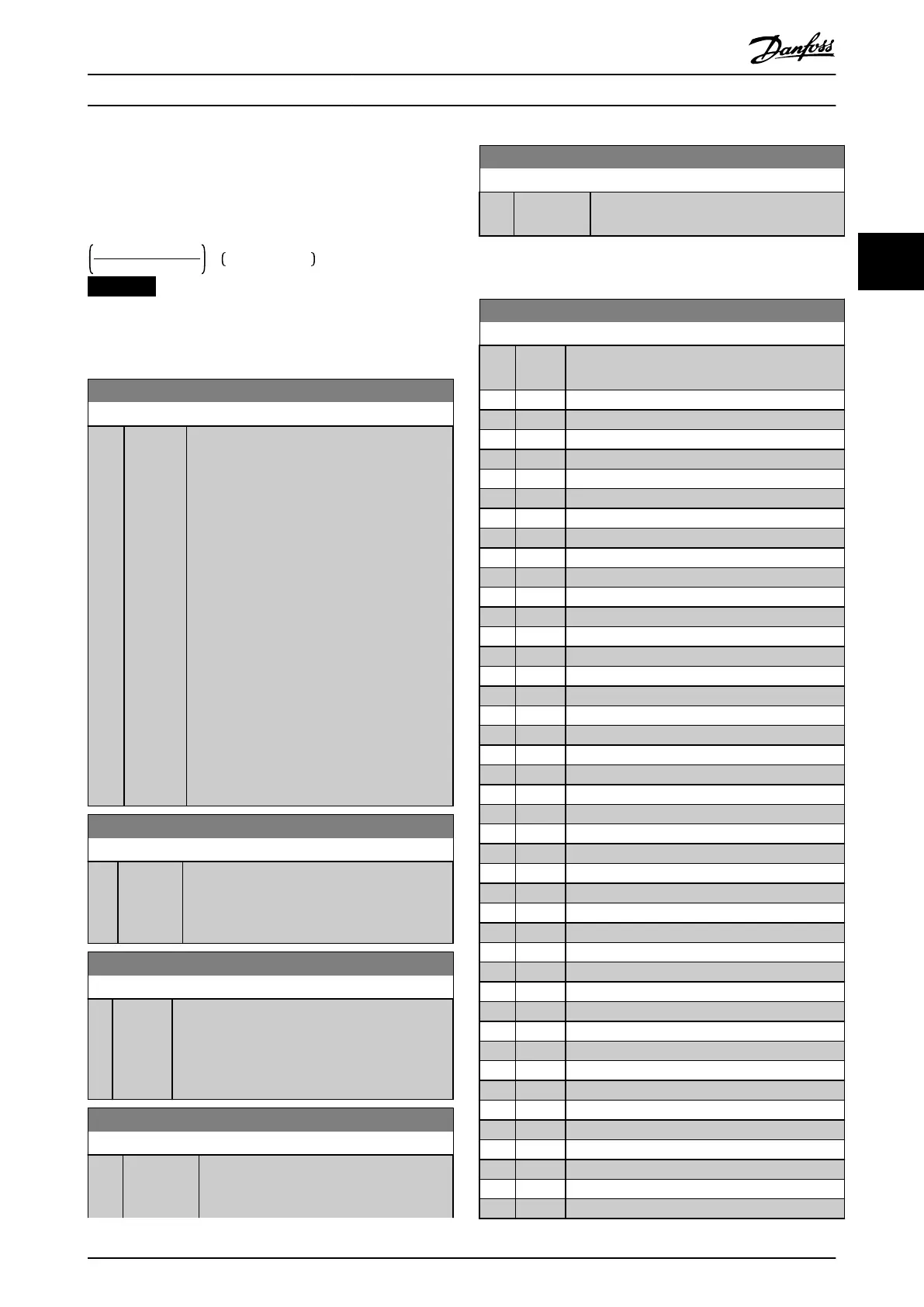

3.18.4 21-3* Closed Loop 2 Ref/Fb

21-30 Ext. 2 Ref./Feedback Unit

Option: Function:

See parameter 21-10 Ext. 1 Ref./Feedback Unit for

details.

[0] *

[1] %

[5] PPM

[10] 1/min

[11] RPM

[12] Pulse/s

[20] l/s

[21] l/min

[22] l/h

[23] m³/s

[24] m³/min

[25] m³/h

[30] kg/s

[31] kg/min

[32] kg/h

[33] t/min

[34] t/h

[40] m/s

[41] m/min

[45] m

[60] °C

[70] mbar

[71] bar

[72] Pa

[73] kPa

[74] m WG

[75] mm Hg

[80] kW

[120] GPM

[121] gal/s

[122] gal/min

[123] gal/h

[124] CFM

[125] ft³/s

[126] ft³/min

[127] ft³/h

[130] lb/s

[131] lb/min

[132] lb/h

[140] ft/s

[141] ft/min

[145] ft

Parameter Description Programming Guide

MG20OB02 Danfoss A/S © 05/2018 All rights reserved. 173

3 3

Loading...

Loading...