3.20.4 23-6* Trending

Trending is used to monitor a process variable over time

and record how often the data falls into each of 10 user-

dened data ranges. This is a convenient tool to obtain a

quick overview indicating where to focus on improvement

of operation.

2 sets of data for trending can be created to make it

possible to compare current values for a selected operating

variable with data for a certain reference period, for the

same variable. This reference period can be pre-

programmed (parameter 23-63 Timed Period Start and

parameter 23-64 Timed Period Stop). The 2 sets of data can

be read from parameter 23-61 Continuous Bin Data (current)

and parameter 23-62 Timed Bin Data (reference).

It is possible to create trending for the following operation

variables:

•

Power.

•

Current.

•

Output frequency.

•

Motor speed.

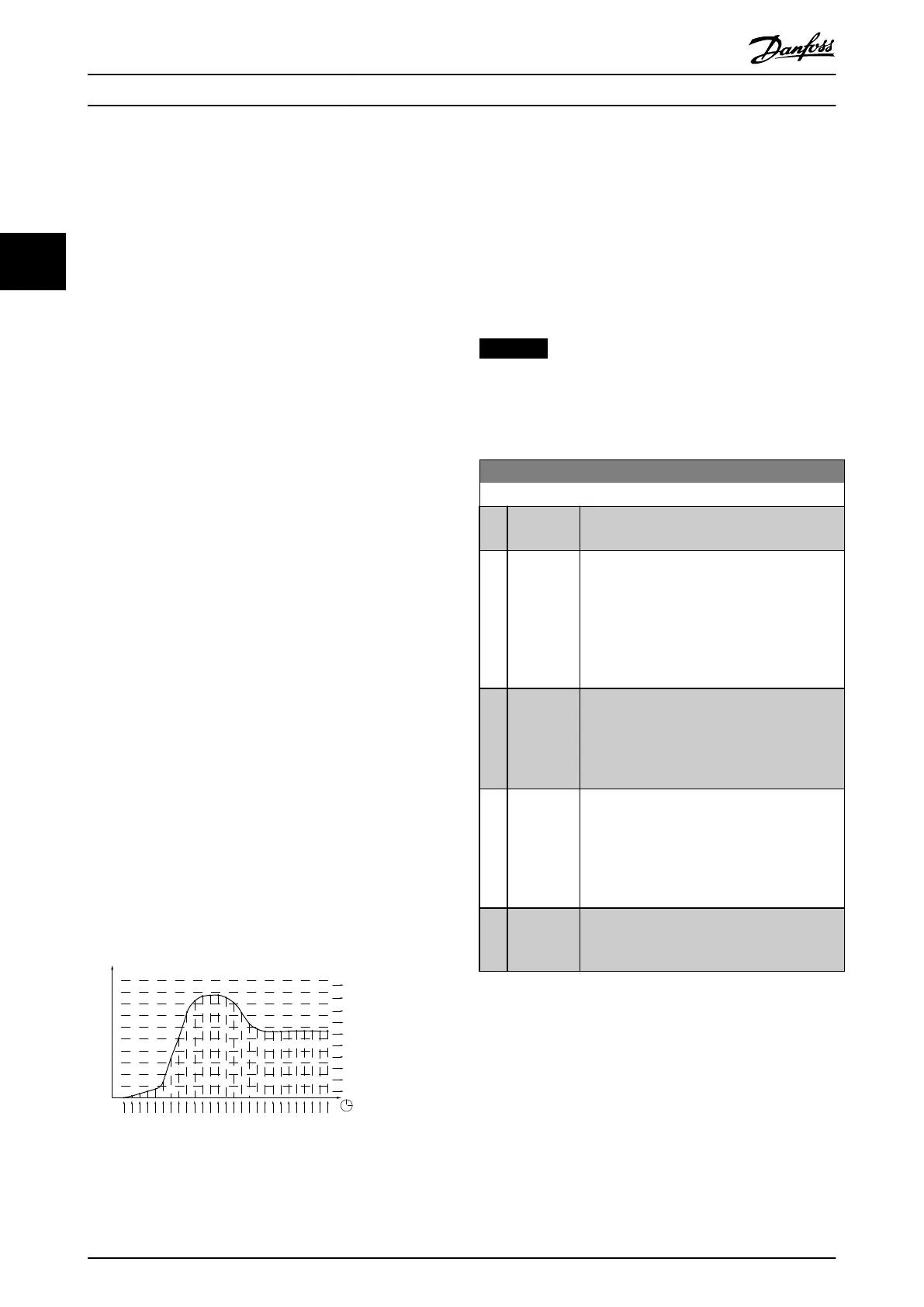

The trending function includes 10 counters (forming a bin)

for each set of data containing the numbers of

registrations reecting how often the operating variable is

within each of 10 pre-dened intervals. The sorting is

based on a relative value of the variable.

The relative value for the operating variable is determined

as:

•

Actual/rated x 100% - for power and current.

•

Actual/max x 100% - for output frequency and

motor speed.

The size of each interval can be adjusted individually, but

is 10% for each as default. Power and current can exceed

rated value, but those registrations are included in 90–

100% (MAX) counter.

Relative value

operating variable

Counter 1: +1

Counter 0: +5

Counter 2: +0

Counter 3: +1

Counter 4: +0

Counter 5: +11

Counter 6: +1

Counter 7: +2

Counter 8: +6

Counter 9: +0

130BA281.10

80

70

50

60

30

40

10

20

%

90

100

Illustration 3.77 Time and Relative Values

Once per second, the value of the operating variable

selected is registered. If a value has been registered to

equal 13%, the counter 10 to <20% is updated with the

value 1. If the value stays at 13% for 10 s, 10 is added to

the counter value.

The contents of counters can be shown as bars on the LCP.

Select Quick Menu⇒Loggings: Trending Continued Bin/

Trending Timed Bin/Trending Comparison.

NOTICE

The counters start counting whenever the frequency

converter is powered up. A power cycle shortly after a

reset resets the counters. EEPROM data is updated once

per hour.

23-60 Trend Variable

Option: Function:

Select the required operating variable to be

monitored for trending.

[0] Power [kW] Power yielded to the motor. Reference for the

relative value is the rated motor power

programmed in parameter 1-20 Motor Power

[kW] or parameter 1-21 Motor Power [HP]. The

actual value can be read in

parameter 16-10 Power [kW] or

parameter 16-11 Power [hp].

[1] Current [A] Output current to the motor. Reference for the

relative value is the rated motor current

programmed in parameter 1-24 Motor Current.

The actual value can be read in

parameter 16-14 Motor current.

[2]

*

Frequency

[Hz]

Output frequency to the motor. Reference for

the relative value is the maximum output

frequency programmed in

parameter 4-14 Motor Speed High Limit [Hz]. The

actual value can be read in

parameter 16-13 Frequency.

[3] Motor

Speed

[RPM]

Reference for the relative value is the

maximum motor speed programmed in

parameter 4-13 Motor Speed High Limit [RPM].

Parameter Description

VLT

®

AQUA Drive FC 202

198 Danfoss A/S © 05/2018 All rights reserved. MG20OB02

33

Loading...

Loading...