Manual DEHLER 39

51 - 72

4.8.1 Rudder blade and rudder bearing

The rudder blade, a modern prebalanced GFK profile with a big rudder force. The rudder

shaft diam. 80 mm is made of aluminium, fixed and getting narrower at the lower end. The

rudder force gets transmitted from the shaft to the rudder blade through welded fittings. The

rudder shaft gets guided through an upper and lower continuously greased JP3 bearing.

4.8.2 Return

Because of the helm hollow, the transmission lever could not go directly from the rudder lever

to the rudder quadrant Therefore we needed to get a return with intermediate bearing

support. Sketch 50 shows the setup of the components.

4.8.3 Steering column

We installed a Whitlock steering column type COBRA 6RDI. Please read through the

attached information and observe the maintenance instructions.

4.8.4 Rudder maintenance

The rudder practically does not need any maintenance. Every five years you should dismount

the rudder and carefully clean, grease and reinstall the bearing surfaces. Take care that the

rudder can only be „pulled“ in a crane or over a depression after loosening the rudder calking

ring. Every year you should check the tightening of the counter nuts of the tramsmission

lever and of the rudder quadrant screws.

LOOK OUT

If the ship sails backwards, don´t go too quick and always cling to the helm.

Don’t ever let go of the helm!

The stop and the crown wheel get damaged by the impact of the rudder!

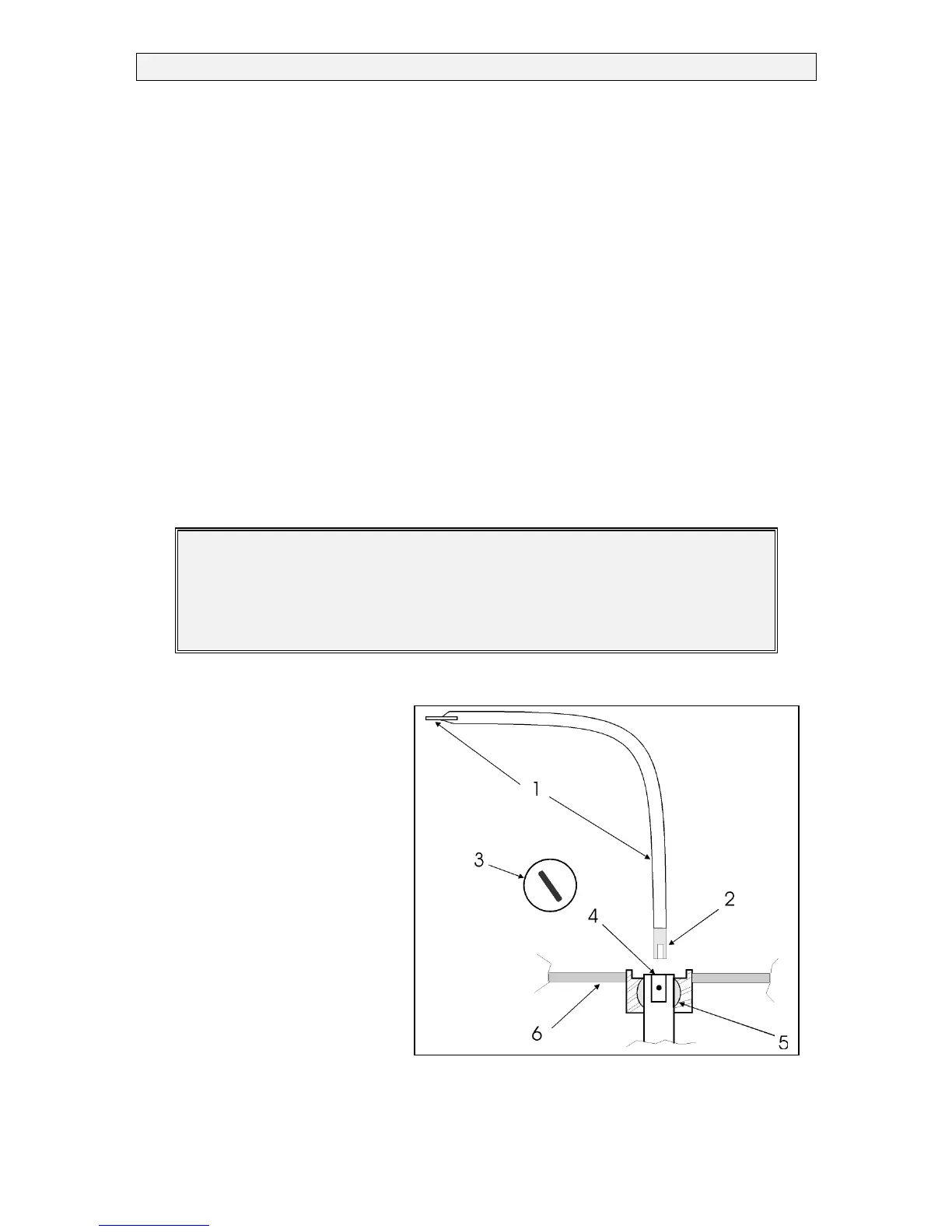

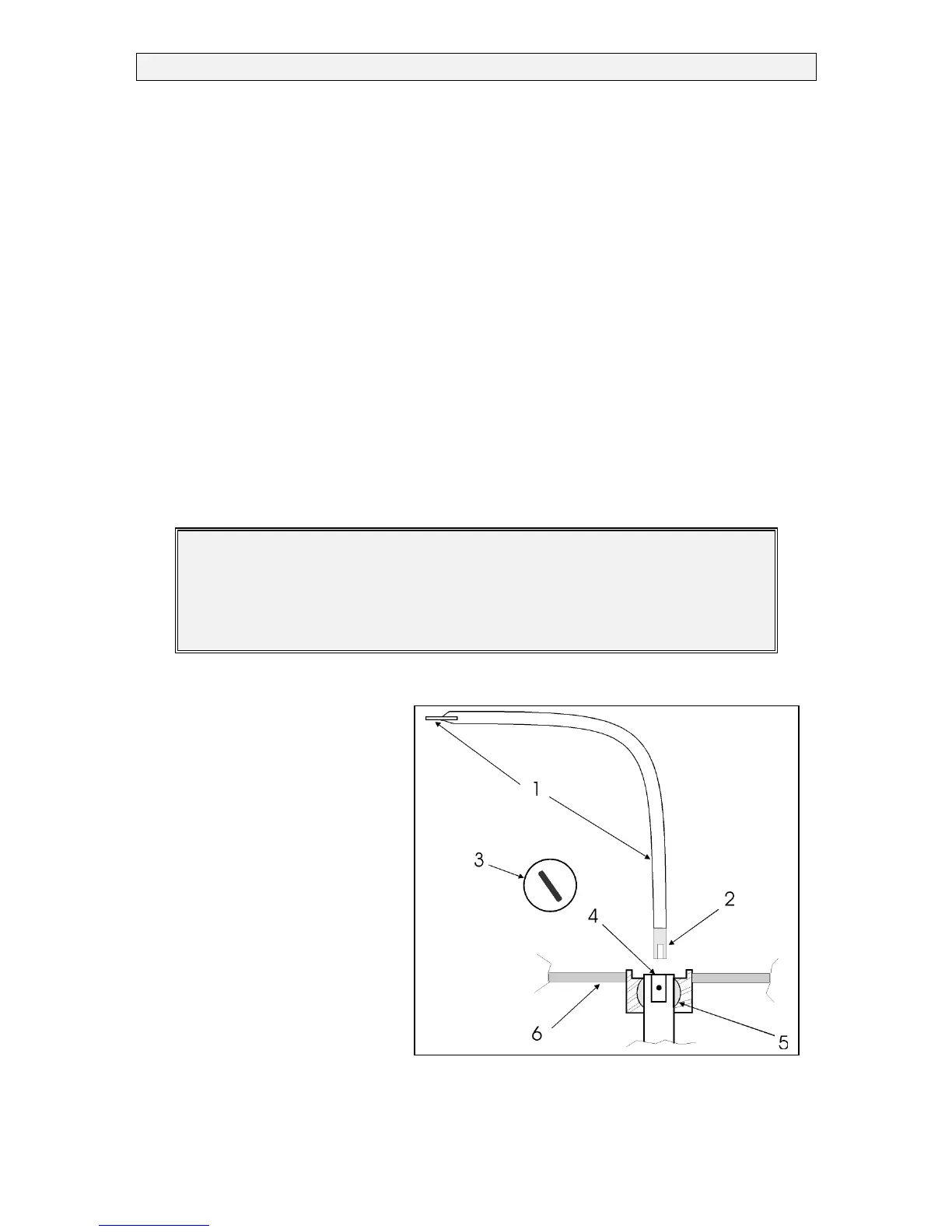

4.8.5 Emergency head

The emergency head is stored in the

port side locker. One end of the

emergency head is in fact a screw,

which can loosen the cover of the

upper bearing. The other end is

equipped with a nut that can be

placed on the bridle at the upper

end of the rudder shaft. As skipper,

you should get used to its handling.

Components

1. Emergency head

2. Nut

3. Cover upper bearing

4. Blind hole with bridle

5. Bearing

6. Cockpit floor

FIGURE.:

EMERGENCY HEAD

Loading...

Loading...