6159932010-09

54 / 60

English

CVIC-MODCVIC-MULTICVIC

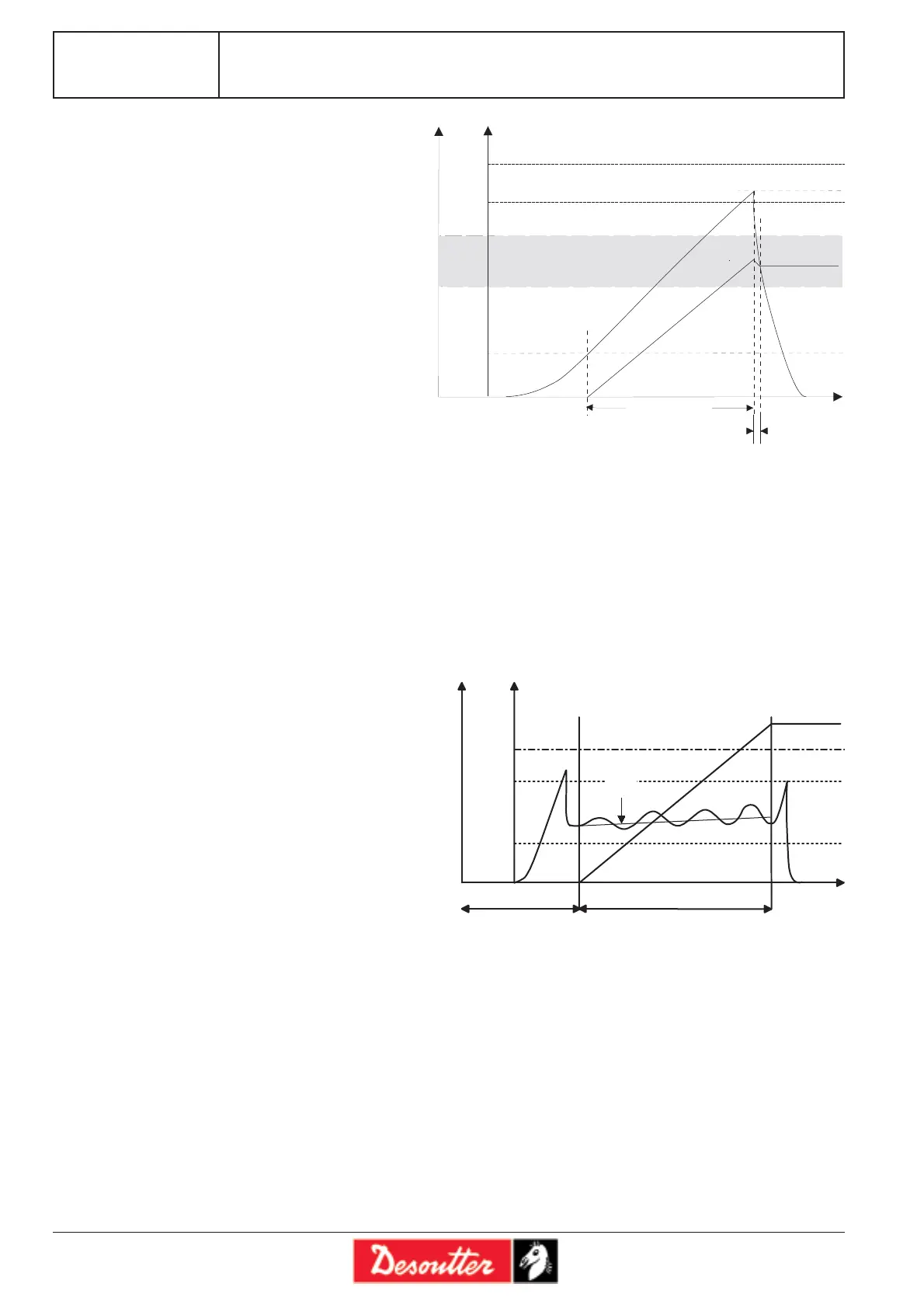

Angle + torque controlled tightening

the recorded values are the following:

final torque and final angle

Spindle stop

IF angle ≥ target angle OR torque > max. torque

Accept report

IF min. torque < final torque < max. torque

IF min. angle < final angle < max. angle

A n g l e

t h r e s h o l d

T i m e

A n g l e

t i g h t e n i n g + s p i n d l e

t o r s i o n

F i n a l t o r q u e

F i n a l a n g l e

a n g l e m e a s u r e d

d u r i n g s p i n d l e b a c k t o r s i o n

( u p t o a n g l e t h r e s h o l d )

T o r q u e

M a x

M i n

M a x

M i n

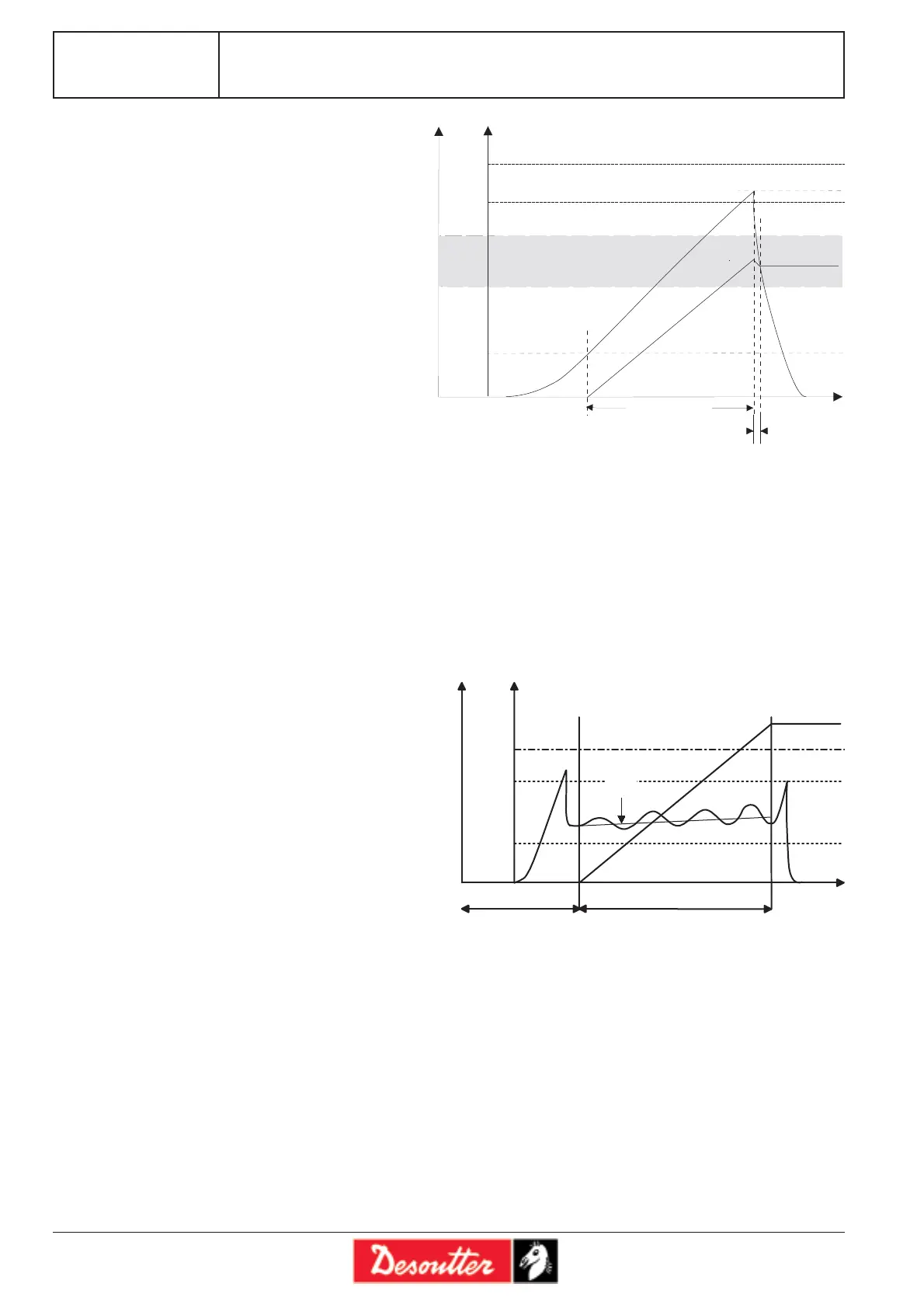

Prevailing torque controlled tightening

This phase allows you to check the residual torque (prevailing torque) that results, for instance from the thread formed with

tapping screws.

It is useful to know if the thread is formed correctly during

the desired number of rotations without untimely locking

or tapping deficiency.

The initial timeout allows you to start the readings when

the tool speed is stabilised. The memorised result is the

mean of the torque readings during the acquisition phase.

The system stops the acquisition of the torque and angle

when the motor stops. The torque pulse at the motor stop

is not taken into account.

Spindle stop IF angle ≥ target angle OR torque> safety torque

Accept report IF min. torque ≤ torque ≤ max. torque

Time

Rise-delay

time

Data

acquisition

safety

Max

target angle

Min

Torqu

mean

torque

Loading...

Loading...