Operation

4812160801_D.pdf 2018-12-17

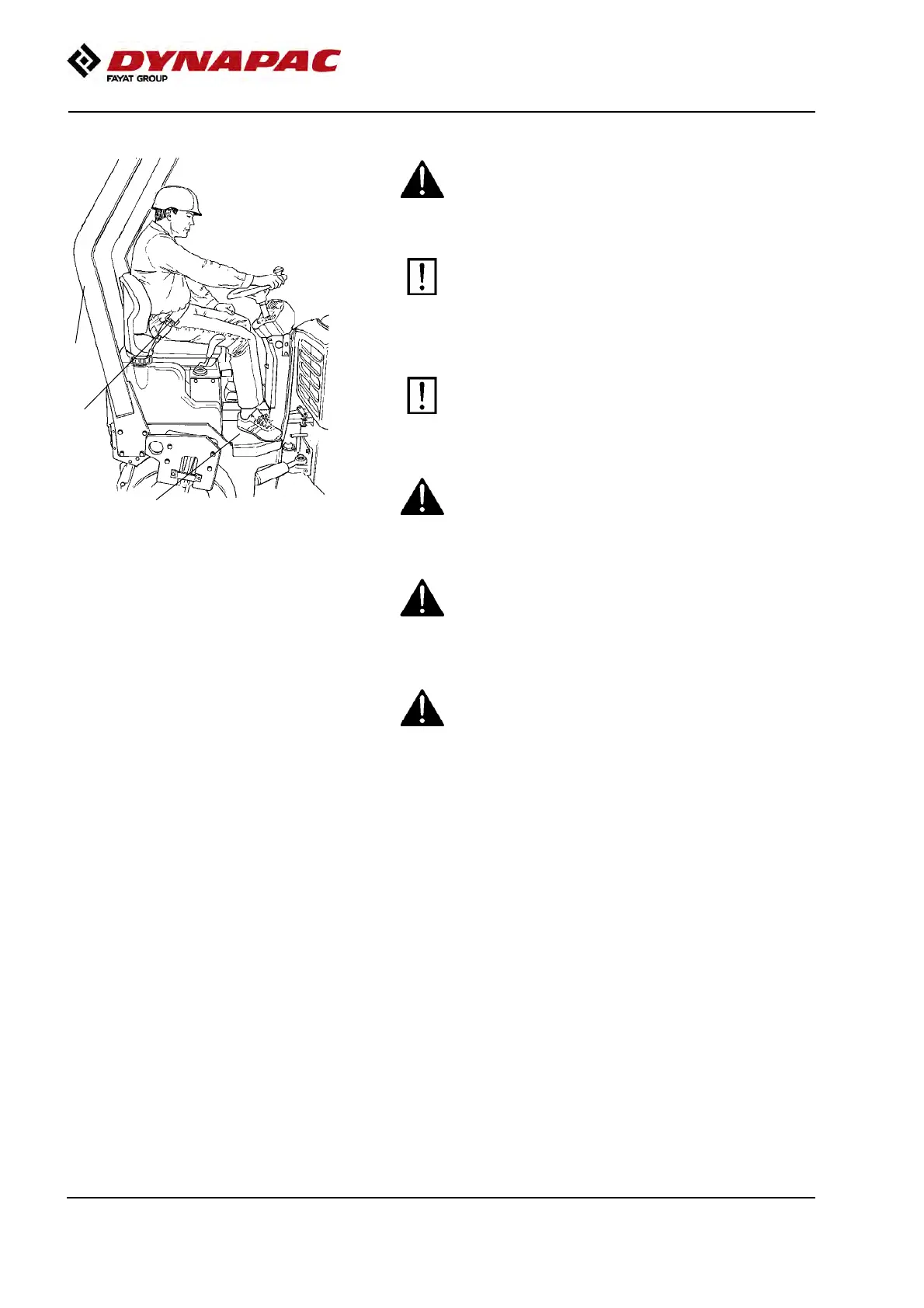

Operator position

1

4, 5

2

Fig. Operator's seat

1. Seatbelt

2. ROPS

4. Rubber element

5. Anti-slip

Replace the seat belt (1) if it shows signs of

wear or has been subjected to high levels of

force.

Replace the seat belt (1) if it shows signs of

wear or has been subjected to high levels of

force.

Never use the forward/reverse levers as a handle

when mounting or disembarking from the roller.

Never use the forward/reverse levers as a handle

when mounting or disembarking from the roller.

Check that the rubber elements (4) on the

platform are intact. Worn elements will reduce

comfort.

Check that the rubber elements (4) on the

platform are intact. Worn elements will reduce

comfort.

Ensure that the anti-slip (5) on the platform is in

good condition. Replace where anti-slip friction is

poor.

Ensure that the anti-slip (5) on the platform is in

good condition. Replace where anti-slip friction is

poor.

Machines with folding ROPS must always be

operated with the ROPS raised and locked in

position.

Machines with folding ROPS must always be

operated with the ROPS raised and locked in

position.

The interlock must always be checked before

operating. To do this the operator stands up from

the seat as shown in the instructions in the

section Operation.

The interlock must always be checked before

operating. To do this the operator stands up from

the seat as shown in the instructions in the

section Operation.

If ROPS (Roll Over Protective Structure) is fitted to the

roller, always wear the seat belt (1) provided and wear

a protective helmet.

38

Loading...

Loading...