153

support@edgeovens.com

Technical Support: +1 (724) 628 3050

SERVICE

To verify the thermocouple, follow the below process:

1. Allow the oven temperature to stabilize (500°F/260°C works well).

2. Measure the ambient temperature of the machine control (MC on back of the control cabinet door). This is

your “Ambient” measurement.

3. Note the temperature on the display. Subtract (10) from this value. This is your “Displayed” temperature.

*10°F is default, verication will be needed.

4. Measure the mVDC output of the connected thermocouple. Red meter lead to the WHITE wire of P3.1,

Black meter lead to the RED wire of P3.2. Note this measurement as the “Measured mVDC” value.

5. Referencing the TYPE-J THERMOCOUPLE CHART, make note of the mVDC value for the “Ambient”

temperature you recorded.

6. Add the mV values “Ambient mVDC” + “Measured mVDC” = “Actual mVDC”

7. Again, referencing the chart, record the Temperature equivalency of “ACTUAL”.

8. “ACTUAL” should be within 15°F of “Displayed” temperature. If not, replace the thermocouple AND the

thermocouple extension.

Replacement of the thermocouple should be made from within the bake chamber. Remove the lower right ngers

to access the thermocouple clip and remove the thermocouple. Pull the thermocouple through the control cabinet

air stopper. Pay attention to the 0.5 inch SS tube, ensure it is not dislodged during reassembly.

THERMOCOUPLE (CONTINUED)

PART FAILURE VERIFICATION

CONTROLS AND ASSEMBLIES (CONTINUED)

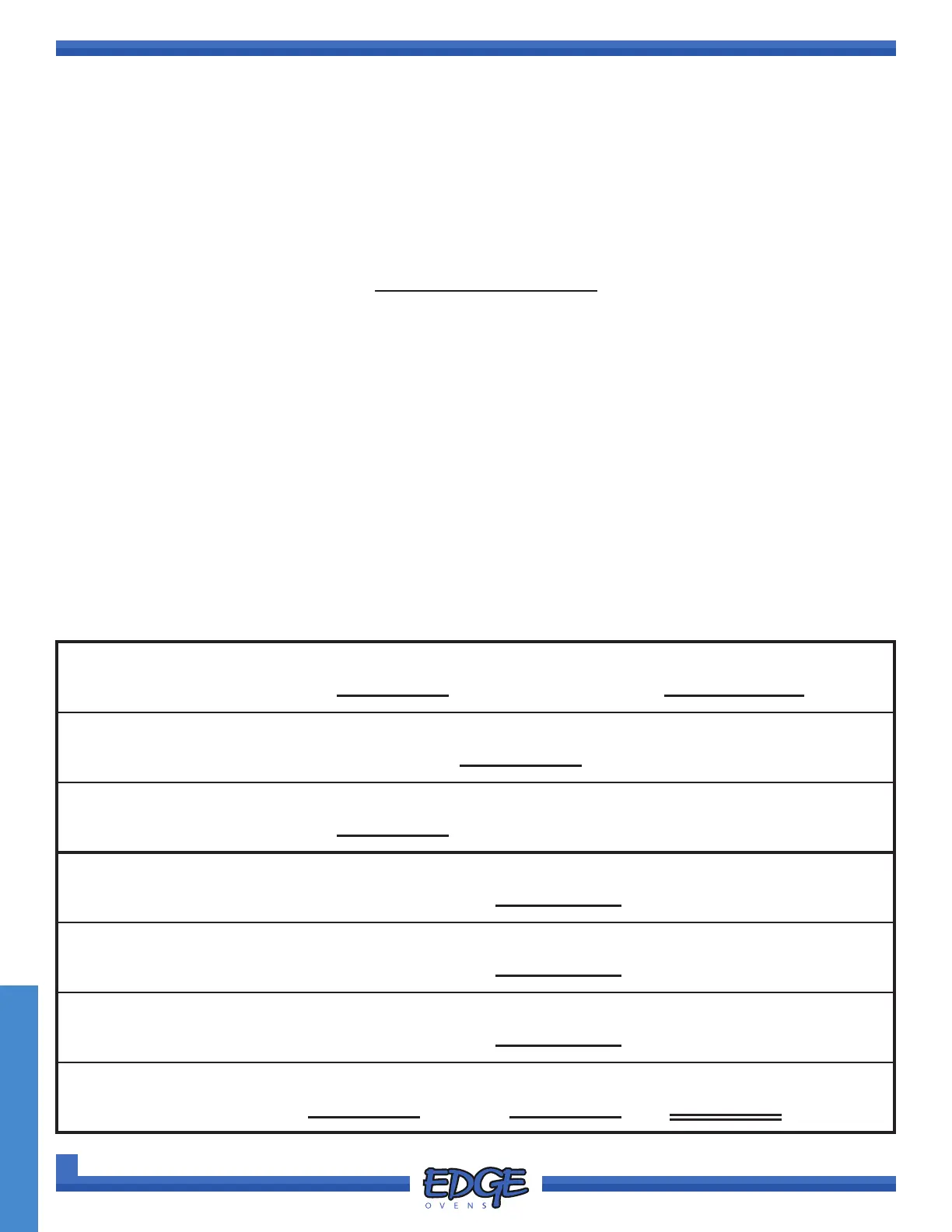

THERMOCOUPLE WORKSHEET

(A) Ambient Temperature =

°F

= mVDC

(D) Displayed Temperature −

10 =

°F

(M) Measured Temperature = mVDC

(A) mVDC

+ (M) mVDC +

= (ACTUAL) mVDC =

(ACTUAL)

°F

− (D)

°F = °F (±15 °F)

(VERIFY OFFSET VALUE)

Loading...

Loading...