33

support@edgeovens.com

Technical Support: +1 (724) 628 3050

INSTALLATION

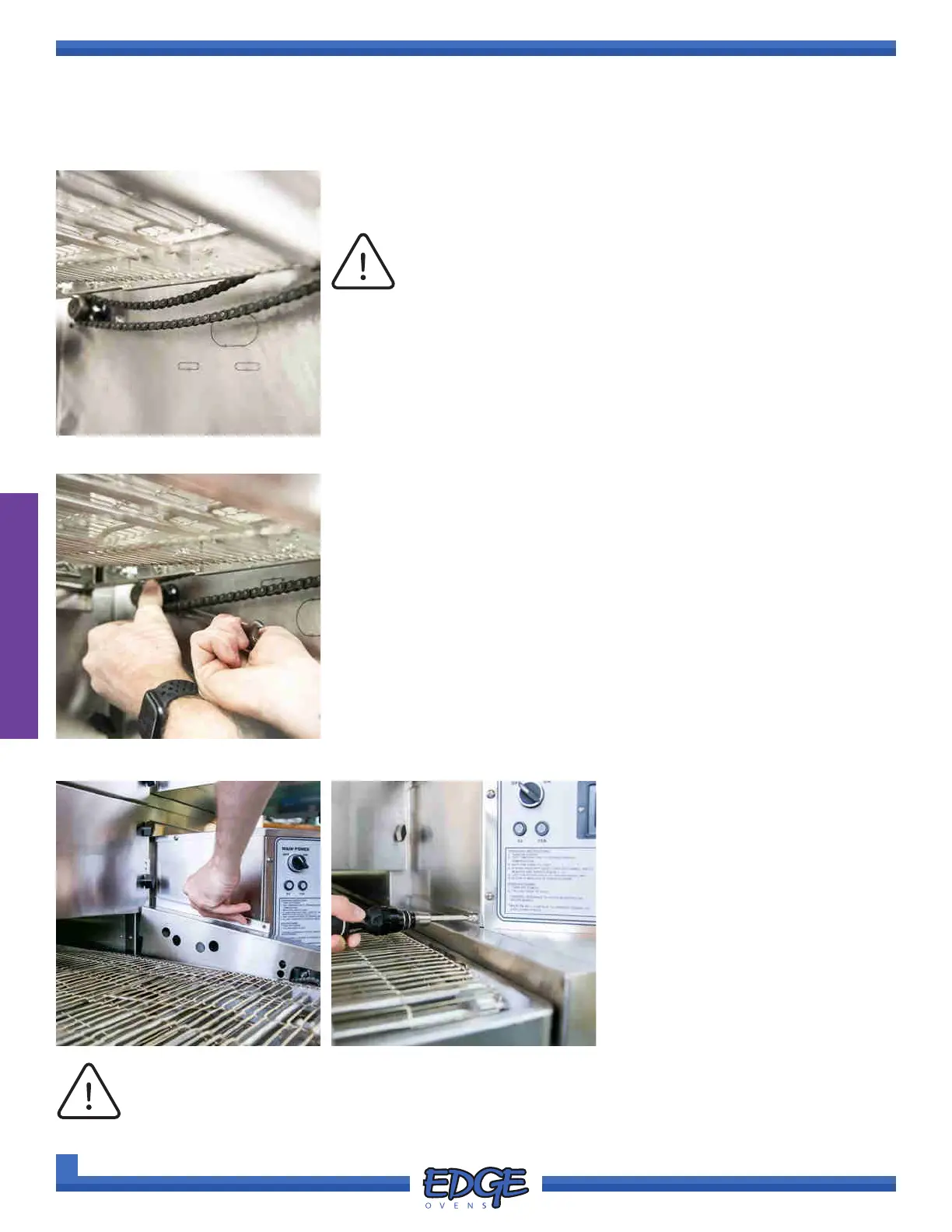

8. Check the tension of the conveyor drive chain. The conveyor drive

chain when properly installed will sit taught with very little slack on the

upper and lower side of the chain. (Figure 2-67)

FIGURE 2-67

FIGURE 2-68

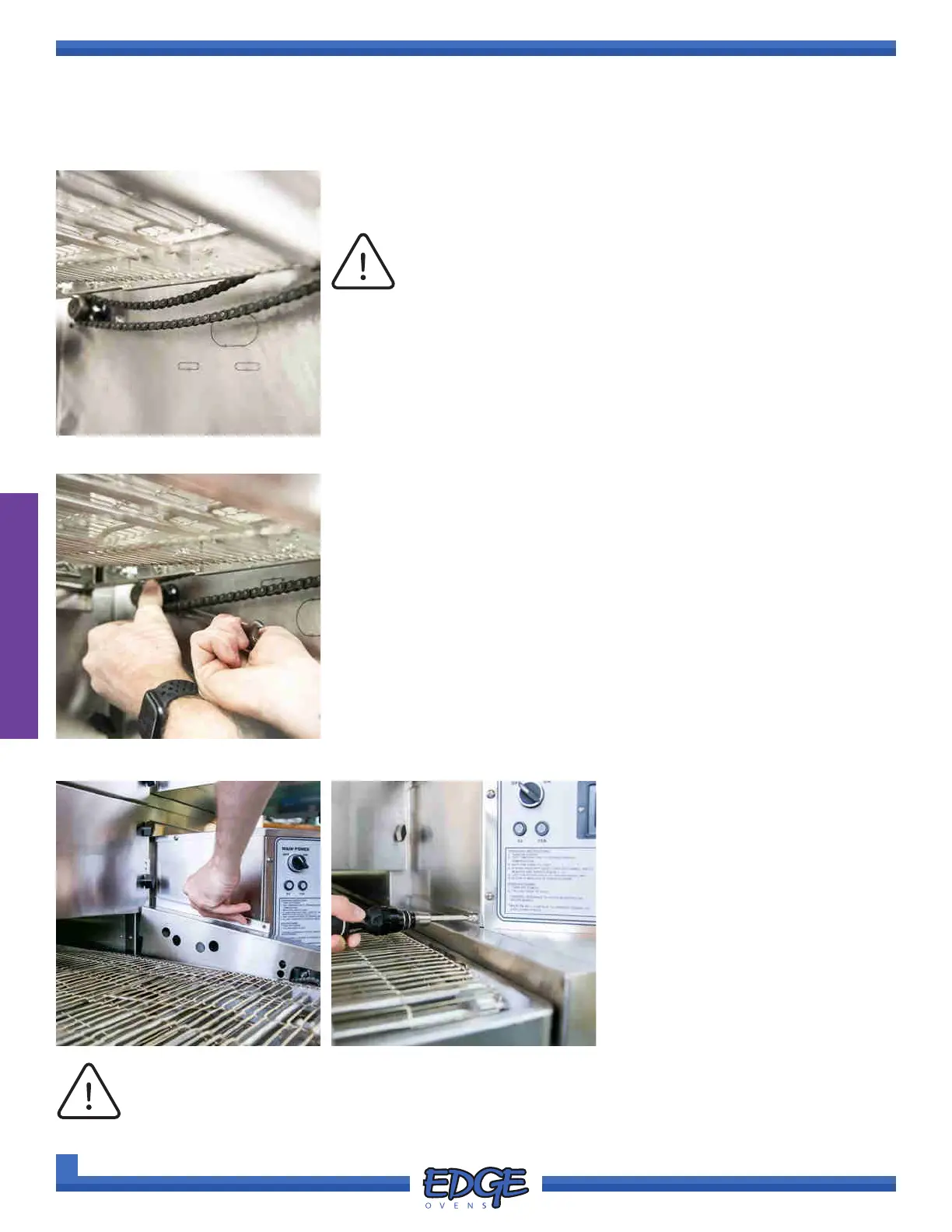

9. If excessive slack does exist on the conveyor drive chain, loosen the

four (4) conveyor motor 1/2” x 1/4-20 bolts with a 7/16” spanner and

push the conveyor motor towards the oven mouth until the slack has

been removed from the upper and lower side of the chain. (Figure

2-68)

OVEN ASSEMBLY

STANDARD CONVEYOR DRIVE SYSTEM ASSEMBLY (CONTINUED)

FIGURE 2-69

10. Tighten the conveyor motor bolts

and recheck tension. DO NOT

exceed 40 inch-lbs torque on the

motor bolts. (Figure 2-68)

11. Install the removed chain guard

(Figure 2-69) and secure in place

with the previously removed

Phillips screw (Figure 2-70).

Removing and reversing the belt when changing the oven belt direction is NOT required.

The conveyor belting used for the EDGE Oven is C-CureEdge, a product of Wire Belt Company of

America. This belting is BI-DIRECTIONAL.

NOTICE

FIGURE 2-70

NOTICE

Excessive slack may result in the drive chain slipping which

causes excessive ware and can result in premature failure.

Loading...

Loading...