CAUTION:

Do not keep the c

ooling water supply on if the pump is not going to be required for

some me, otherwise, water condensing outside the pipe might cause corrosion of

element.

Refer to Table: Stop sequences for the stop sequences.

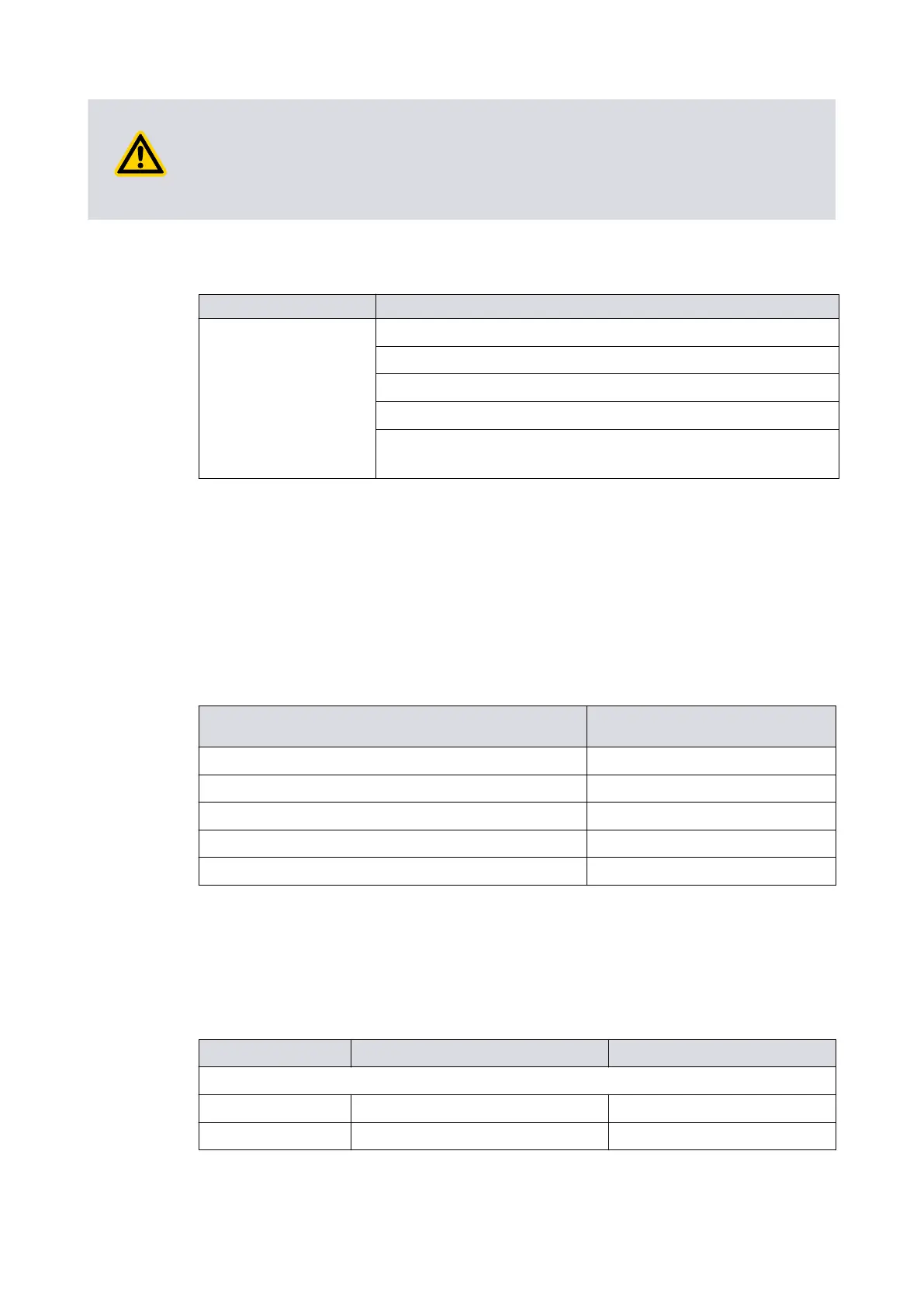

Table 16

Stop sequences

Sequence Descripon

Stop sequence

Inlet purge gas valve is opened.

Inlet isolaon valve is closed (if ed).

Pump runs for 15 minutes before stopping.

Close all gas purge aer the pump stops.

Switch o water-cooling by closing both inlet and outlet aer

at least 60 minutes aer pump stops

If the pump is not going to be required for some me, switch o the electrical supply

and the cooling water supply. Seal the pump inlet and exhaust to prevent any moisture

in the atmosphere from corroding the pumping mechanism.

6.3 Automac shut down

Normally, if an alarm condion exists, the control system will shut down the dry

pumping system. When the dry pumping system shuts down, the pump stops.

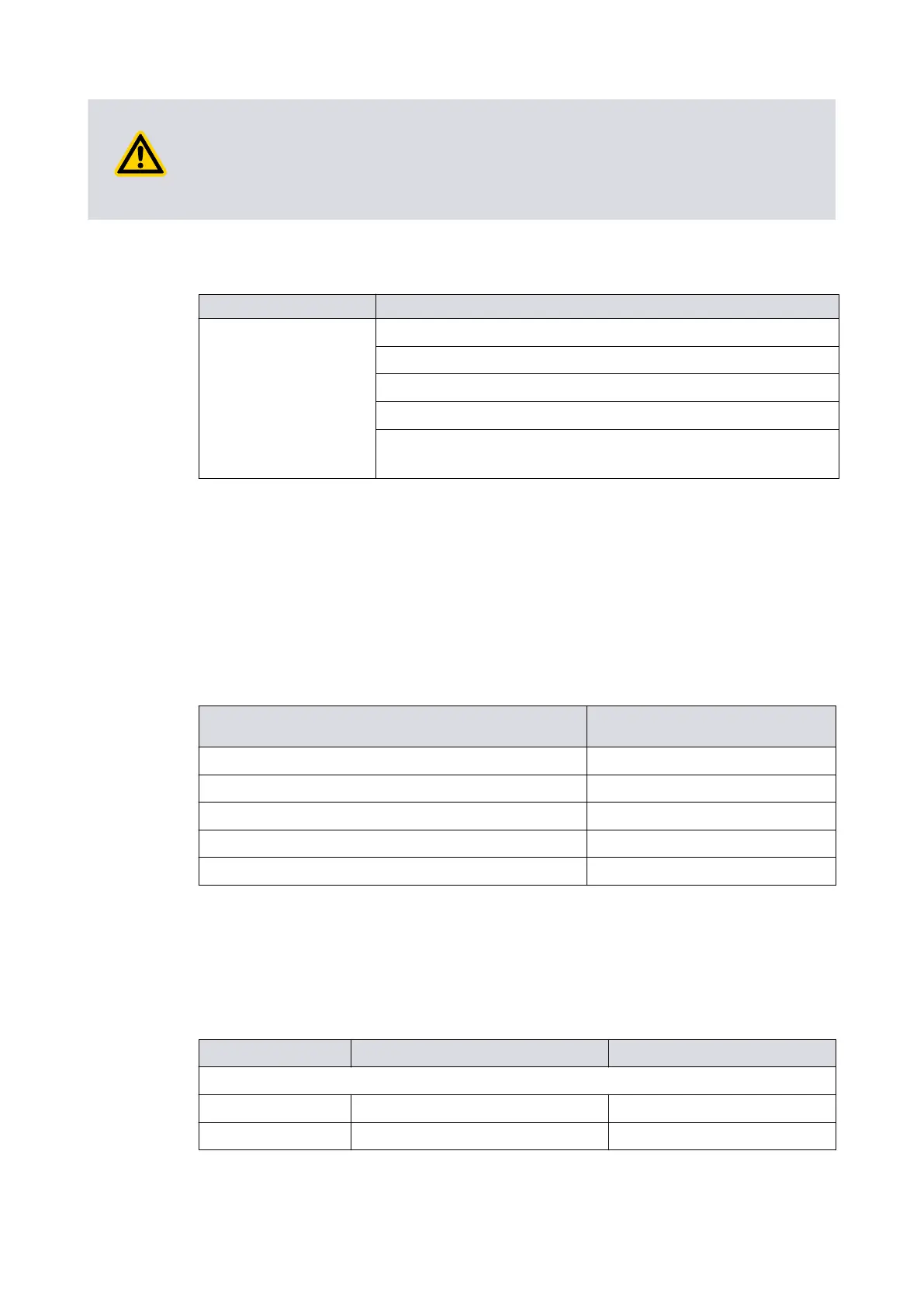

Table 17

Alarm acons

Alarm descripon

Alarm stops the dry pump

EMS Yes

Stator temperature is over 130° C Yes

Motor snap switch tripped Yes

Overload relay tripped Yes

Inverter overload Yes

6.4 Unplanned shut down and alarms

The dry pumping s

ystem is ed with thermal protecon sensors that will give warnings

and alarms. Refer to Table: Pump protecon sensors.

Table 18

Pump protecon sensors

Sensor

Warning condion triggered Alarm condion triggered

DP TEMP temperature

EXS750 120 °C 130 °C

EXS450 120 °C 130 °C

Refer to Automac shut down on page 52 for informaon about alarms and automac

shutdown condions.

07/2021 - ©Edwards Limited

Page 52A41870880_A

A41870880_A - Operaon

Loading...

Loading...