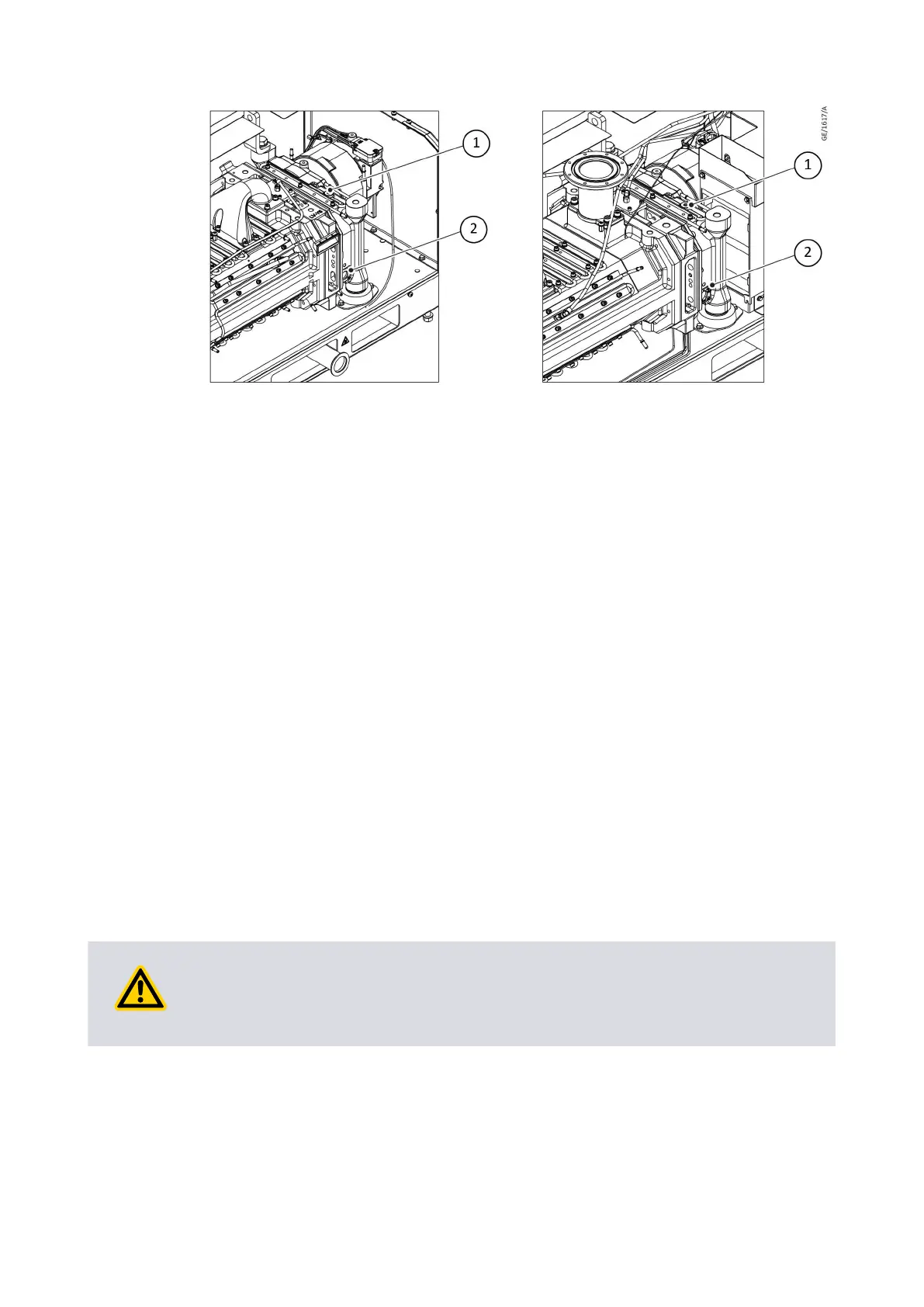

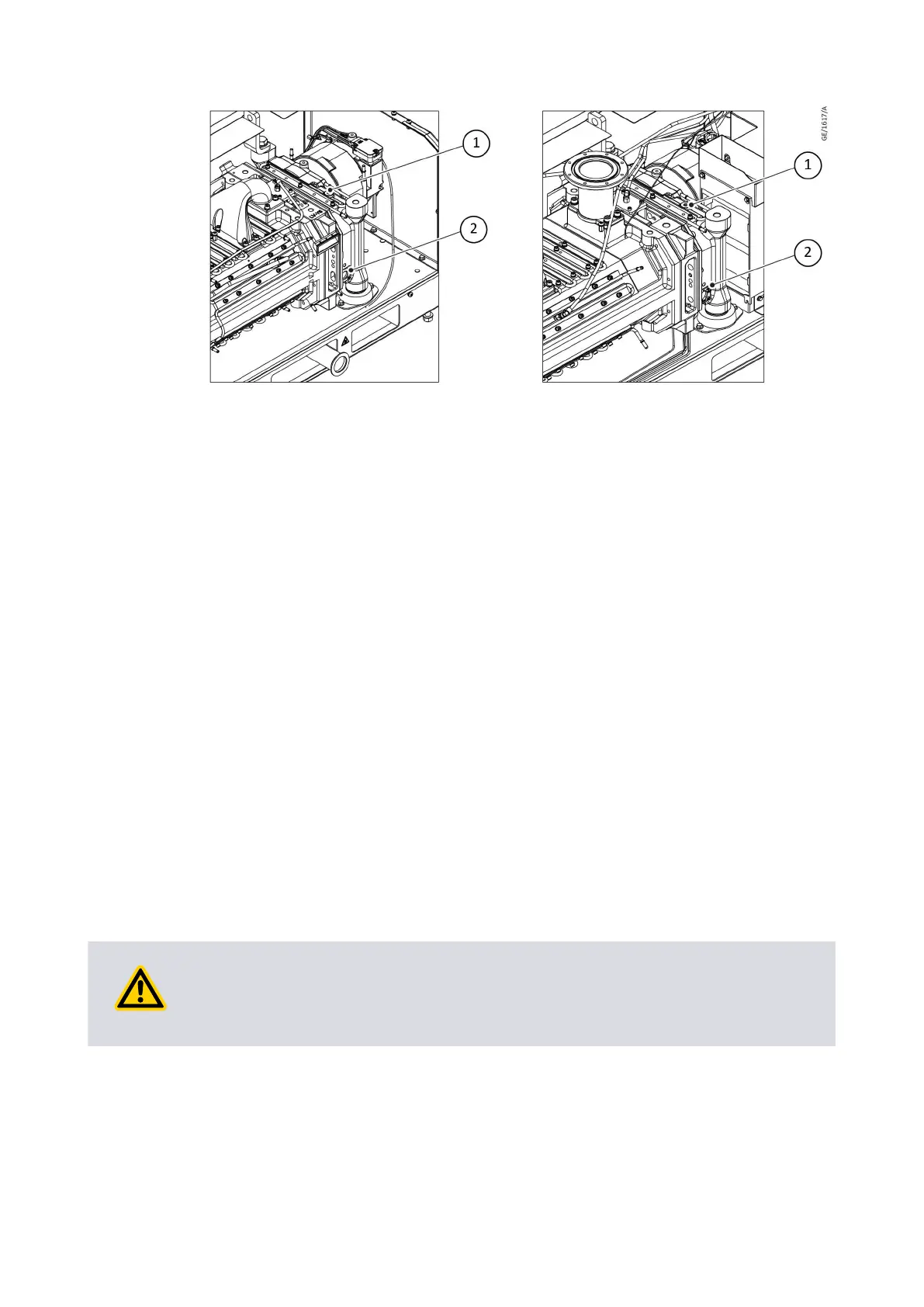

1. Oil ller plug 2. Oil sight glass1. Oil ller plug 2. Oil sight glass

If the oil is very old or has light con

taminaon then it is possible to replace the oil,

contact us for more informaon.

7.5.2 Inspect the connecons, pipelines, cables and ngs

Depending on the applicaon, inspecon and cleaning of the exhaust pipe and any

elbows or check valves ed may be needed. Contact us for details and training. If the

dry pumping system is not relocated for maintenance, ensure that all supplies are locked

out and tagged out before starng the following procedure.

1. Remove the enclosure side and top panels.

2. Check that all the connecons ar

e secure, ghten any loose connecons. Inspect

all cables, pipelines, hoses and connecons and check that they are not corroded

or damaged and do not leak, repair or replace any pipelines, hoses and

connecons that are corroded or damaged, or which leak.

3. Ret the enclosure side and top panels.

For the areas with hard water or sites with the poor cooling water quality it may be

necessary to clean the cooling water pipes to prevent blockages and reducons in

cooling eciency. The equipment and chemicals for pipe cleaning are commercially

available. Contact us for more informaon.

7.6 Overhaul

WARNING:

Do not aempt t

o overhaul the pump without our training and tooling.

We provide a full range of overhaul opons worldwide. We can provide training, tooling

and spares to enable the users to overhaul their pumping systems. Contact us for more

informaon.

07/2021 - ©Edwards Limited

Page 60A41870880_A

A41870880_A - Maintenance

Loading...

Loading...