Service

111

• Release the push button (43).

• Close the furnace, squeeze the tube (6) tightly and

press and hold the button (43).

If the pressure on gauge (12) remains constant, then the furnace has to be

checked for leaks.

If the pressure shown on gauge (12) drops then the leakage has to be found

somewhere along the furnace inlet system.

5.7.1

118BFurnace inlet system - leaks

• After following the above instructions, check for gas leakage between inlet

tube (6) and reverse valve (V2).

5.7.1.1 Leaks in the furnace

After following the above instructions, close the furnace, squeeze tube (9) tightly,

press and hold the button (43), observe the pressure gauge (12).

If the pressure drops, then the furnace is leaking.

• Check whether the O-rings (16), (17) and (18) are soiled or defective see

Operation Manual.

• Check whether the combustion tube (15) is broken or cracked.

– If the pressure remains constant, then the furnace outlet system is leaking.

5.7.1.2 Leaks in the furnace outlet system

• After following the instructions in the section "Leaks in the furnace", check if

the handle (8) is properly shut, or else there will be a major gas leak from the

dust filter.

• Check the following components for leakage, by squeezing the following

tubes, while pressing and holding the button (43):

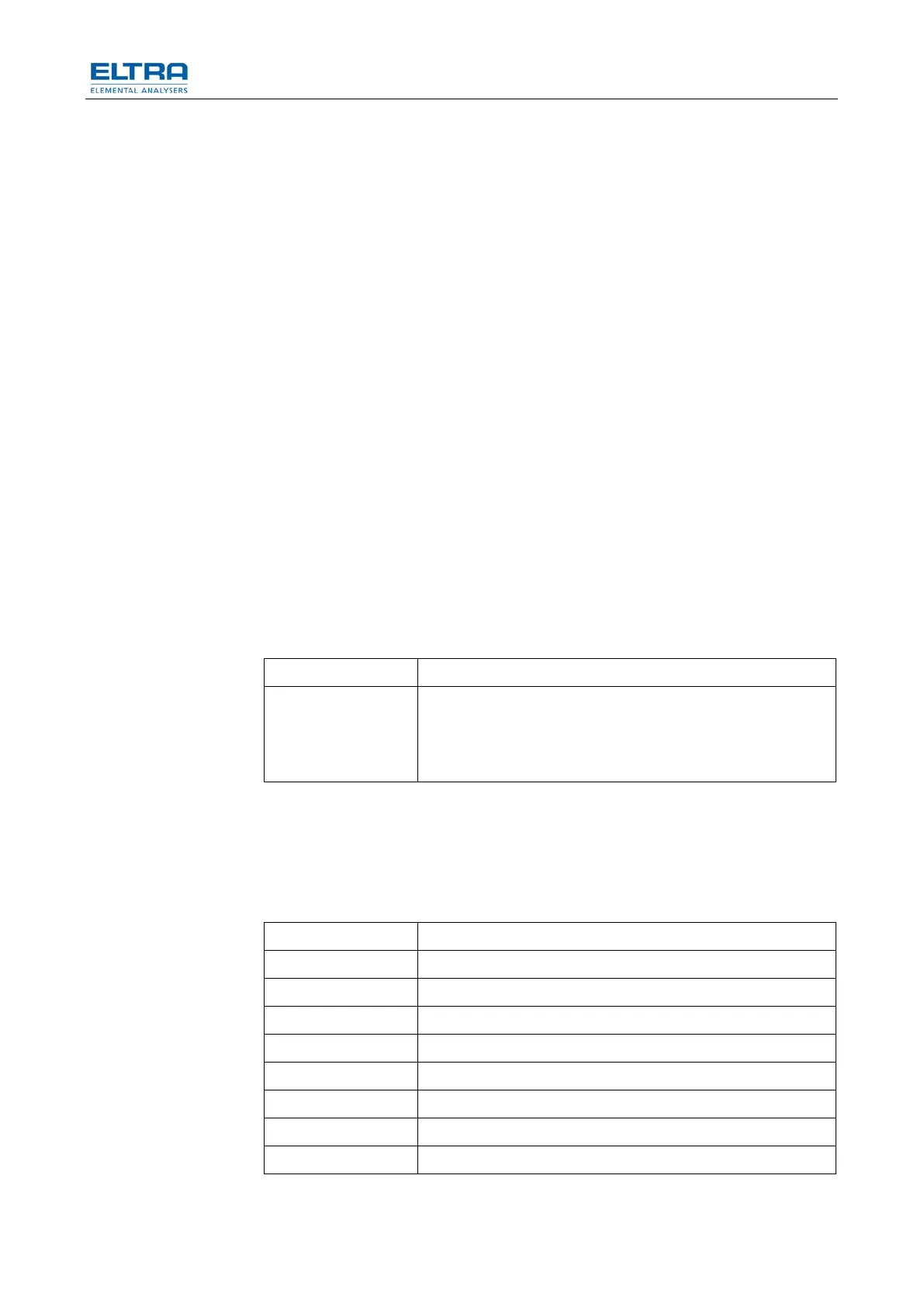

Tube to squeeze Leak location

19 dust trap (10)

glass tube (11)

dust filter cartridge (13)

outflow valve (V1)

5.7.1.3 Leaks inside the analyzer

When pressing the button (43), the gauge (12) shows a pressure drop while the

furnace is open then locate the leakage, according to the sequence below.

• Keep the furnace opened.

• Squeeze the following tubes tightly, while pressing and

holding the button (43):

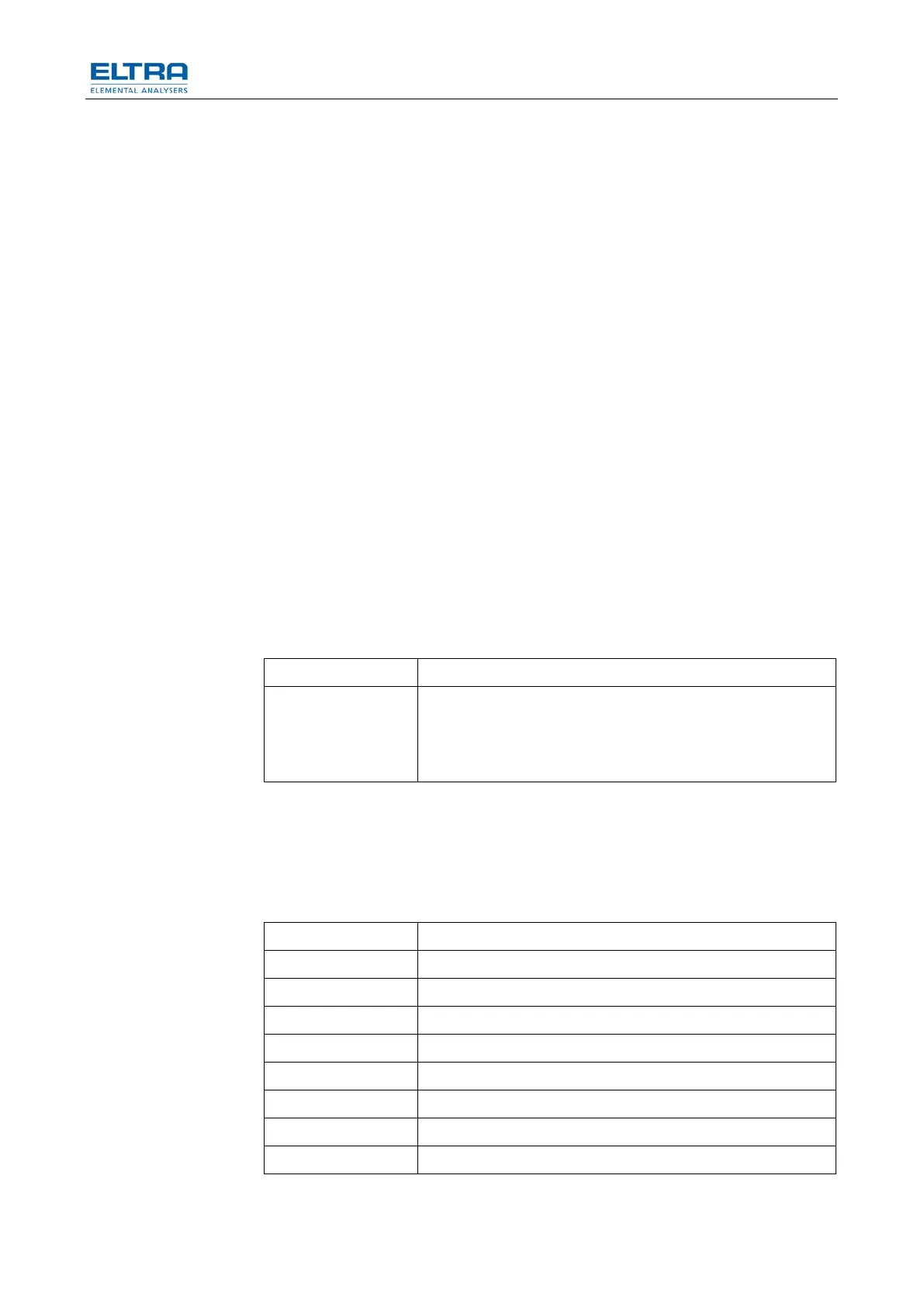

Tube to squeeze Leak location

4 Exhaust valve (V9)

37 Flow meter (40)

34 CO2-Paths (38)

31 SO3-Trap (35) or oxidizing furnace tube (36)

24 SO2-Path (32) or flow sensor (33)

23 Regulator valve (V6)

22 Pressure regulator (PR3)

44 Bypass valve (V4), check for 24 VDC on input pins

Loading...

Loading...