46

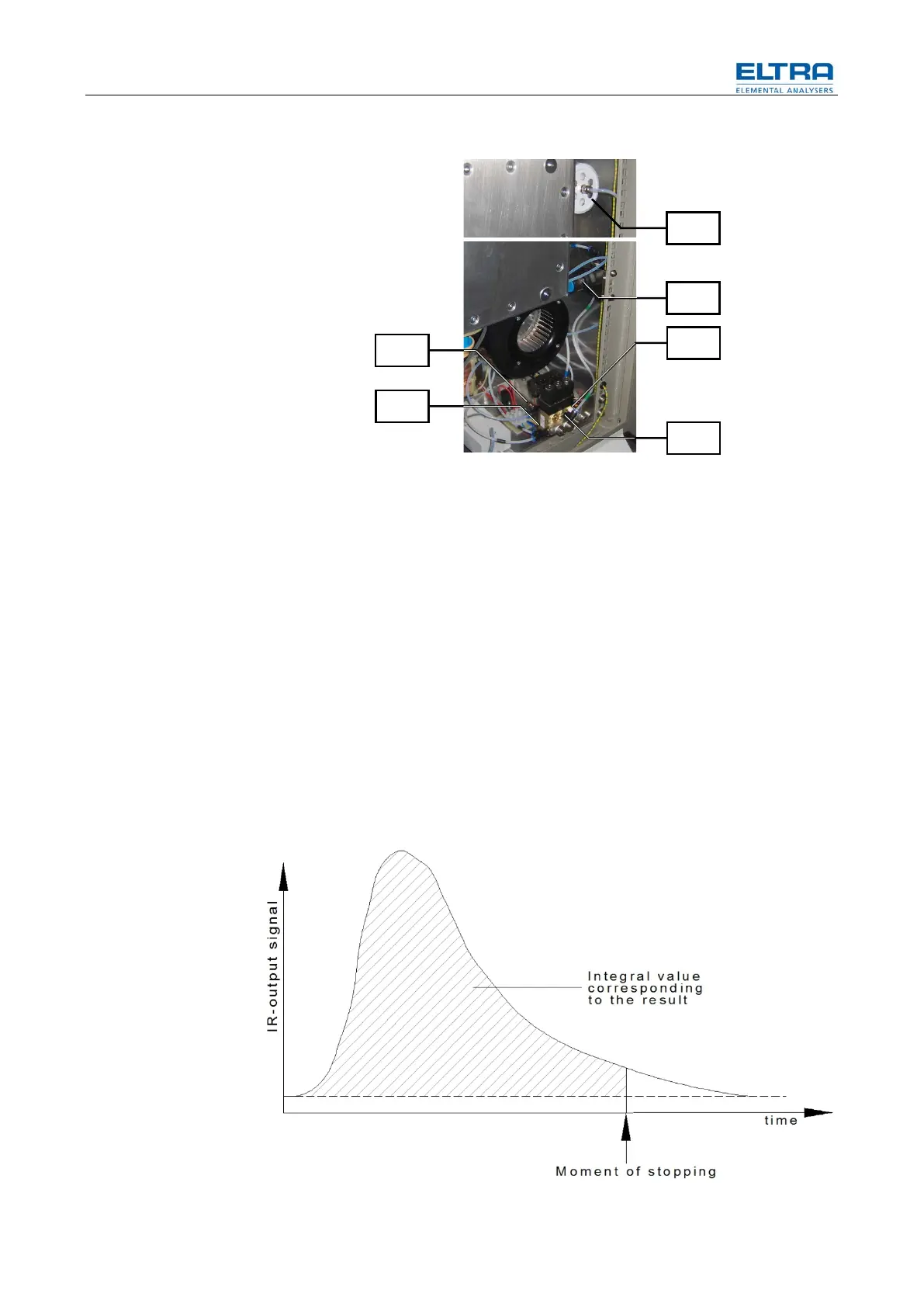

Fig. 24: Pneumatics (photo)

Little or no compressed air pressure, the furnace cannot close.

This pressure is shown on gauge (13), on the front-side of the analyzer.

It must be between 4 to 6 bar (60 to 90psi).

The screw (2) must be turned counter-clockwise, as much as possible.

Adjust regulator (8), so that the furnace floor can rise completely, without shaking;

while a person still can stop the moving furnace floor with only one hand.

This is a safety precaution.

Repeat above instruction, until the adjustment is completed. Now, the upward

speed is fast enough, yet safe for the operator. The pressure regulator (8) is found

on the inside, on the right-side section of the analyzer, installed on the rear panel.

One of the pneumatic valves (V7) or (V10) (or both) is malfunctioning.

The magnetic coil of the pneumatic valve (V7) or (V10) is not powered. The

furnace floor goes up, when valve (V10) receives 24 VDC.

The 24 V DC comes from the microcontroller board; if not, replace the electronic

drivers.

Pos: 5.19 /0 020 Über sc hrif ten /ELT RA 1.1 Über sc hri ften /11 Anal ys eda uer zu l ang - Th e analysi s tak es too long ELTR A @ 6\mod_1368613082100_9.docx @ 40314 @ 22 @ 1

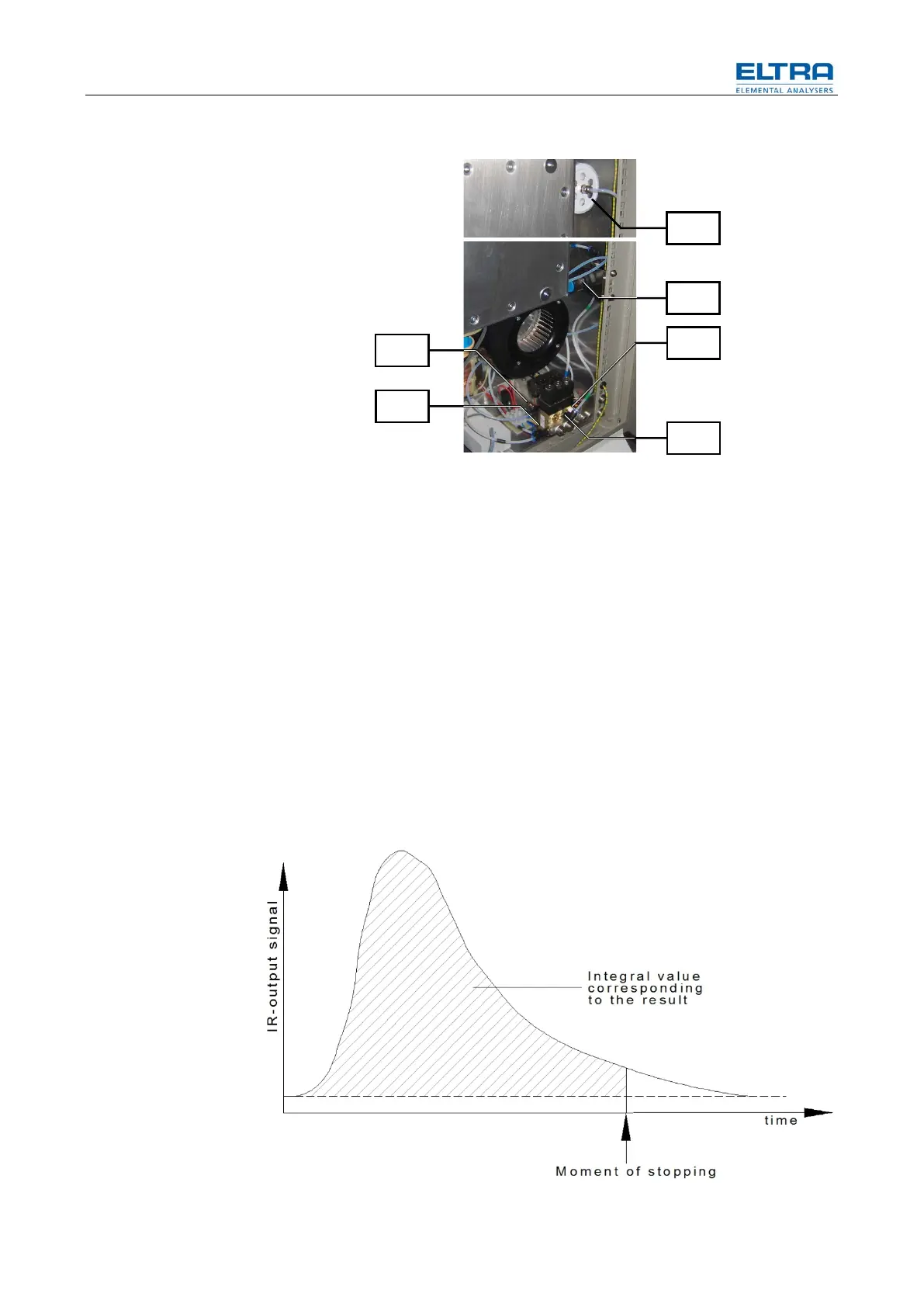

3.8 21BAnalysis takes too long

Pos: 5.20 /0 010 ELTR A/ 0015 s ervic e_i nstr ucti ons/C S-8 00_ Ser vic e/00 15 F ehl er/ 015 0 Mo dul An alys edau er z u l ang ELT RA @ 6\ mod_1377688604344_9.docx @ 46591 @ 2224 @ 1

12

11

9

15

Loading...

Loading...