50

Pos: 5.21 /0 020 Über sc hrif ten /ELT RA 1.1 Über sc hri ften /11 D e velo pme nt of dus t whe n cl osing th e fur nac e ELTR @ 6 \mod_1368620567231_9.docx @ 40336 @ 22 @ 1

3.9 22BDevelopment of dust when closing the furnace

Pos: 5.22 /0 010 ELTR A/ 0015 s ervic e_i nstr uc tio ns/C S-800 _S ervic e/ 001 5 F ehler /01 55 M od ul E ntwic kl ung von St aub bei m Sc hli eße n d es Ofe ns ELT RA @ 6\mod_1377688605074_9.docx @ 46603 @ 2 @ 1

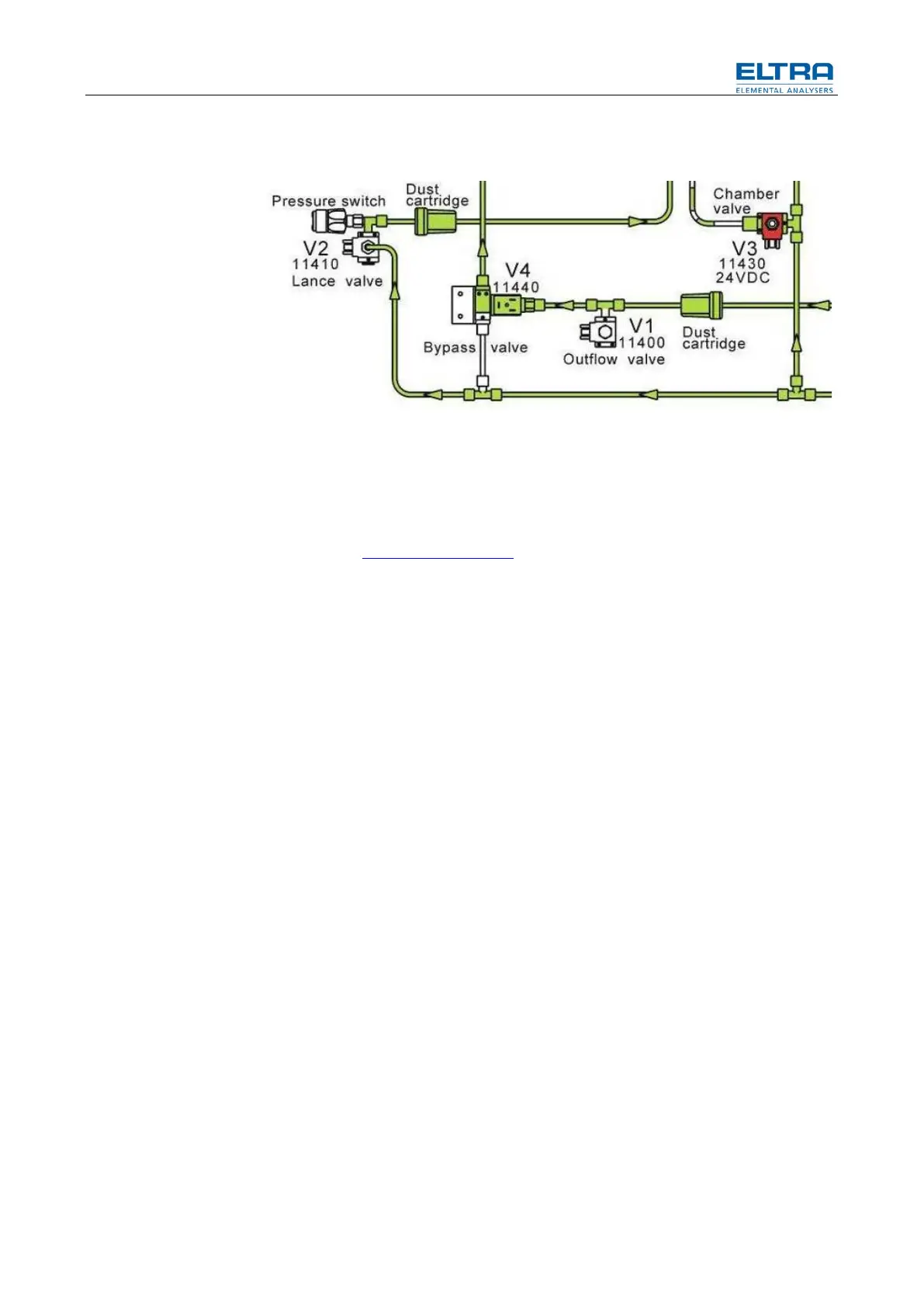

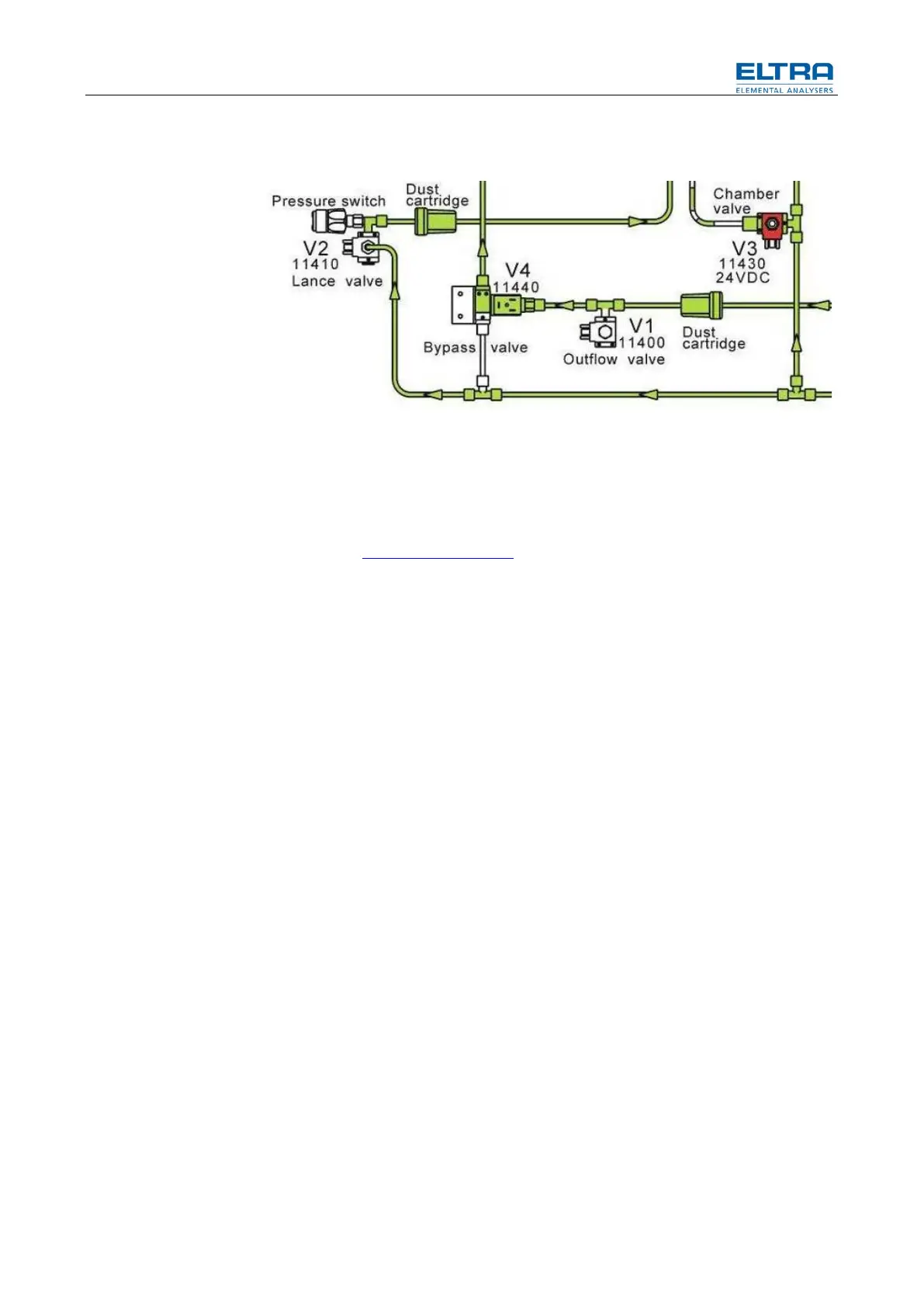

Fig. 26: Gas-flow diagram - furnace closed

This happens when there is no restrictor in the left hand fitting of the valve V3 or

the internal diameter of the restrictor is too large. This can easily be checked when

removing the connected tube.

The restrictor should have an internal diameter of 1 mm.

See draft “Gas-flow diagram - furnace closed”

in the chapter Modification Overview .

Pos: 5.23 /0 020 Über sc hrif ten /ELT RA 1.1 Über sc hri ften /11 U nr egel mäß ige Erg ebni ss e - Ir reg ular res ults E LTR A @ 6\mod_1368621241035_9.docx @ 40358 @ 22 @ 1

3.10 23BIrregular results

Pos: 5.24 /0 010 ELTR A/ 0015 s ervic e_i nstr uctio ns/CS-8 00_Ser vic e/001 5 Fehler /016 0 Modul Unregel mäßi ge Erg ebniss e ELTR A @ 6\mod_1377688605378_9.docx @ 46615 @ 2 @ 1

There are a lot of different reasons for this:

– Saturated chemicals or clogged dust filter

– Heterogeneous samples

– Leakage

– Flow problems

– The electronic noise or drift of the infrared signal

– It can happen quite often that the combustion start is delayed and the

analysis time is too long

– You will see that the message "waiting for stability" is displayed in the status

window

– Incomplete or bad combustion

– Too high blank value for the crucible and tungsten. This will be especially

noticeable, mostly though, in the low carbon channel

– Widely different weights of the sample and the accelerator (tungsten)

Loading...

Loading...