93

- Shift the switch with holder downwards until the magnetic switch is off (A

valve clicks and the piston slightly moves downwards).

- Make a second marking on the cylinder (6) at the upper end of the switch

holder (4).

- Adjust the switch holder (4) to have the upper end in the middle of the two

markings.

- Open the furnace and then close it again (F2) to verify the correctness of the

adjustment.

- Adjust the lower cushioning (7), so that the furnace opens without the piston

banging at the bottom.

- Click on “Communication test”-“Digital outputs”, on the 9th button counting

from the left, to energize the coil cooling valve (11/V8), or start analysis

cycle.

- Turn the restrictor (12) counter clockwise until the pressure on the gauge

(13) is reduced by about 0.2 to 0.3 bar (3 to 4 psi) when the coil cooling

valve (11/V8) is open.

- Fix the locknut of the restrictor (12).

Remark:

In case of using valuable gas for operating the pneumatics, the restrictor (12)

should be adjusted for lower flow by turning it clockwise. It can even be completely

closed by turning it clockwise up to the end of its range.

The flow adjusted with this restrictor is for cooling the combustion coil to ensure

very long service life. According to our experience, the combustion coils of our

analyzers don’t need replacement, even after years of operation.

Pos: 7.19 /0 020 Über sc hrif ten /ELT RA 1.1 Über sc hri ften /11 Pres sur e r egul ati on E LTR A @ 6\ mod_1369298860002_9.docx @ 41930 @ 32233 @ 1

4.4 46BPressure regulation

Pos: 7.20 /0 010 ELTR A/ 0015 s ervic e_i nstr uc tio ns/C S-800 _S ervic e/ 002 0 Ei nst ell unge n, T ests u nd F unk tio nsbe schr eib ung /0 255 M odul Pr es sur e Reg ula tio n @ 6\mod_1377688630939_9.docx @ 46975 @ 2424 @ 1

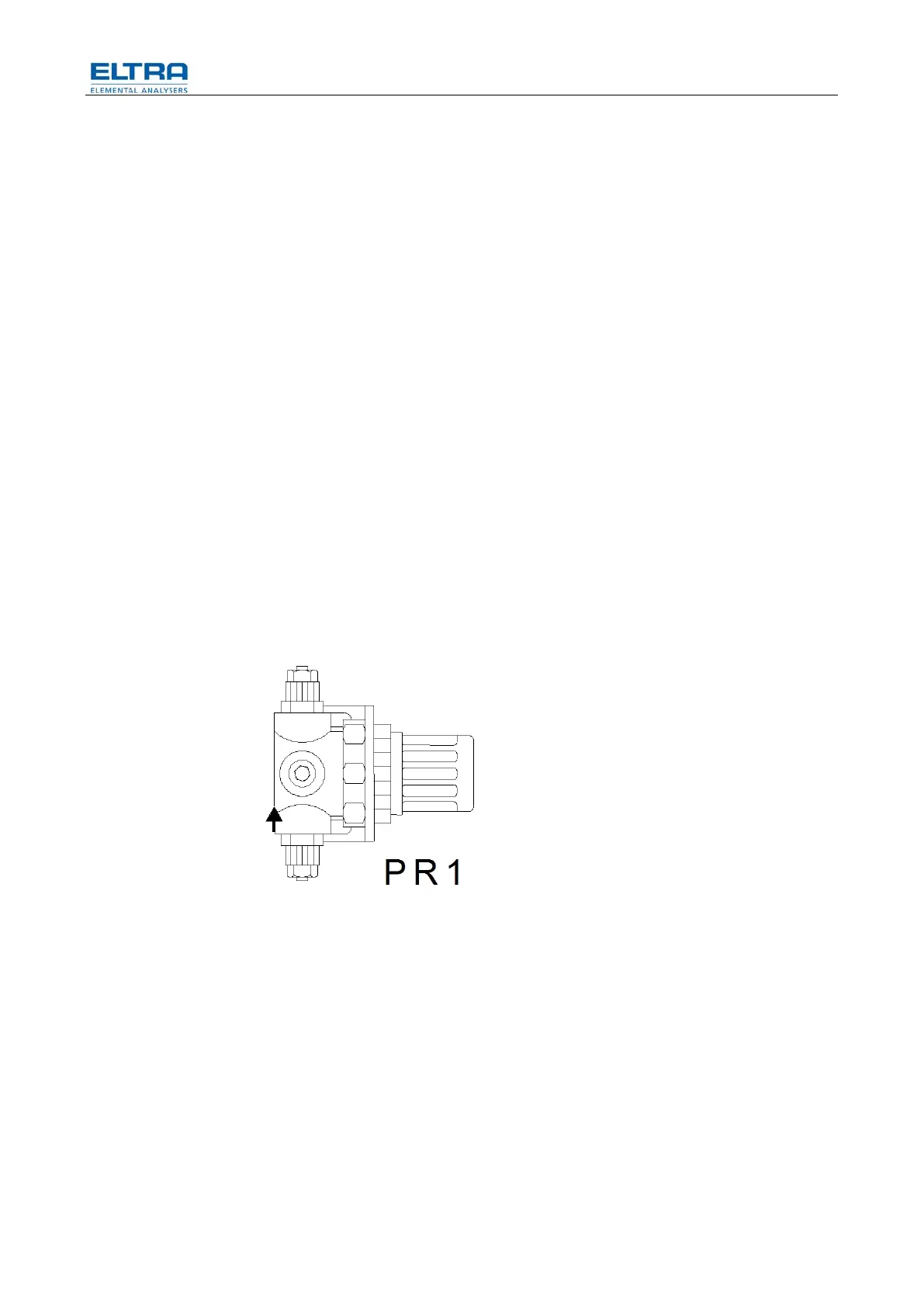

Fig. 48: PR1

PR1 is the inlet oxygen regulator, and is situated inside the analyzer, on the rear

panel.

The outlet pressure needs to be set to 1.5bar (22.5psi).

• Pull and rotate the knob of the regulator, until the pressure gauge (6) shows

the correct value.

– Ensure that the flow shown on the flow meter (5) shows between 180 and

200l/h; if not, adjust according to the related chapter.

Loading...

Loading...