72

3.29.2 99BCopper oxide has a bad quality

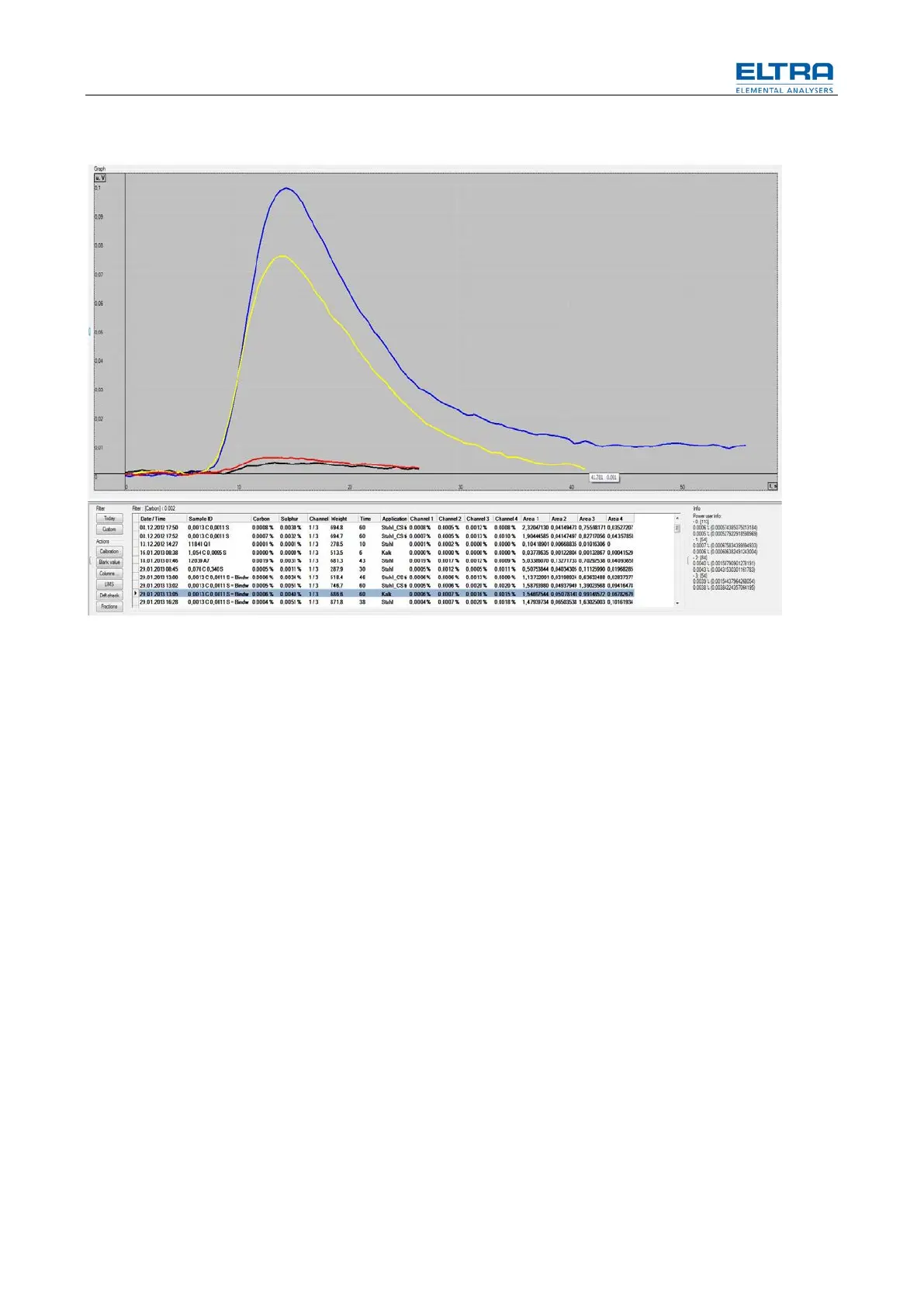

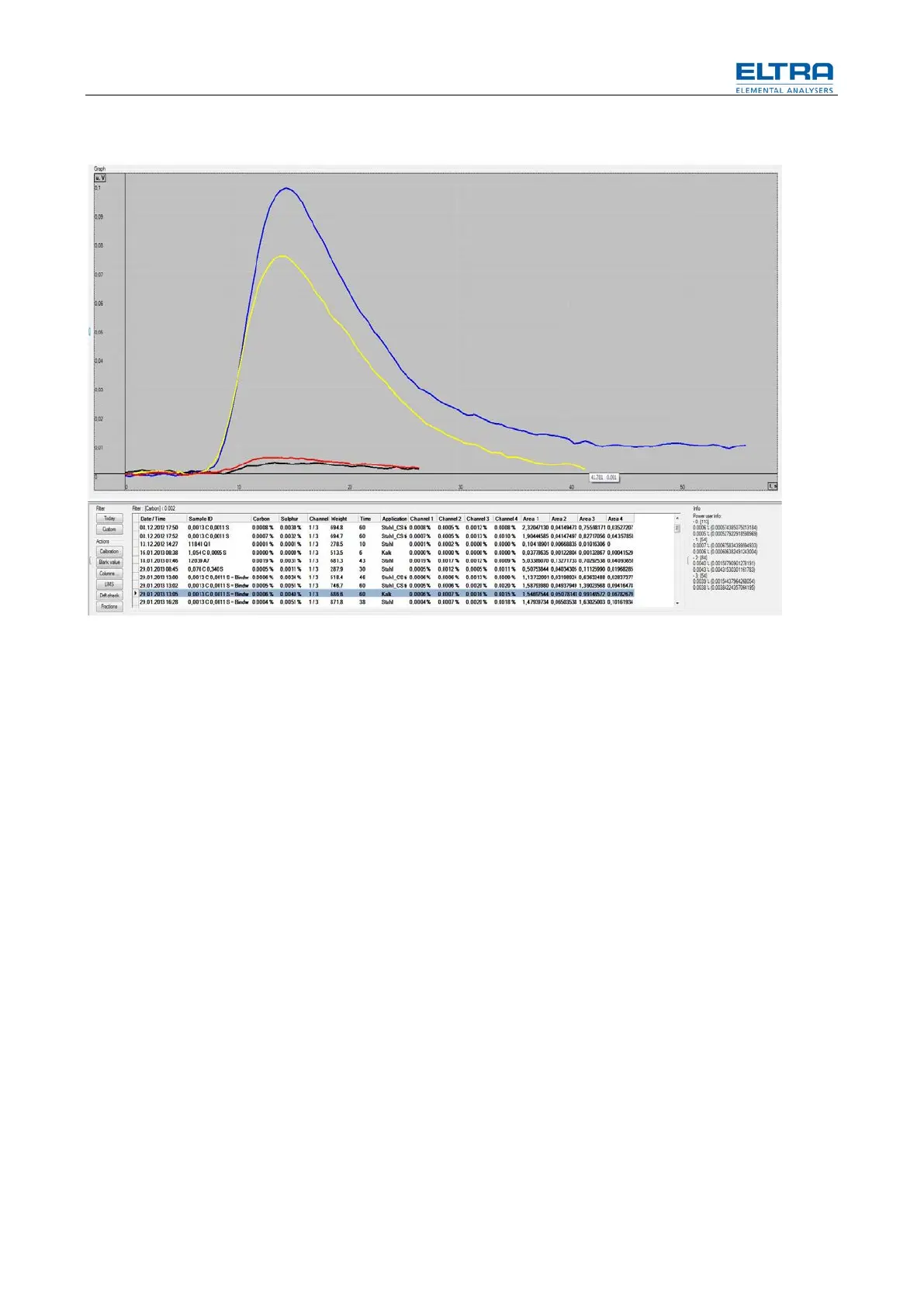

Fig. 25: Programm screenshot (graph example 2)

Memory effects of the copper oxide can cause tailing of the low carbon range in the

level of 10 to 50 mV. However the tailing level does not grow due to faulty copper

oxide.

Possible solution:

-Replace the copper oxide

3.29.3

100BPath window is not sealed or it is broken

If the faulty window is on the chopper housing side, all available cells have a tailing

due to combustion gases entering the chopper housing causing permanent IR

absorption for all cells available.

If the faulty window is on the IR sensor side, there is tailing of the damaged cell

only.

Solution:

-Replace the part having the faulty window.

Replacing the window only, is rather tricky because the window should be

available, the faulty window must be removed, the surface for gluing new window

must be cleaned from old glue and rests of the broken window, there must be glue

available being suitable to glue windows (two components glue) and time should

also be available to wait until the glue is solid.

Loading...

Loading...