60

– Check if the pressure gauge for compressed air (5) shows 4 to 6 bar

(60 to 90 psi).

– Check if the cock (3) is properly shut, or else the O-ring (4) will not seal.

Check if the O-ring (4) is in a good condition.

– Check if the combustion tube is broken or cracked.

– Check for gas leakage.

– Check if the chemicals are saturated and have become hard.

– The paper filter could also be the cause. For changing the paper filter, read

the operating manual.

3.17.2

94BOn the rear-side of the analyzer:

The contents of the gas cleaning furnace could be worn out and clogged.

3.17.3

95BInside the analyzer:

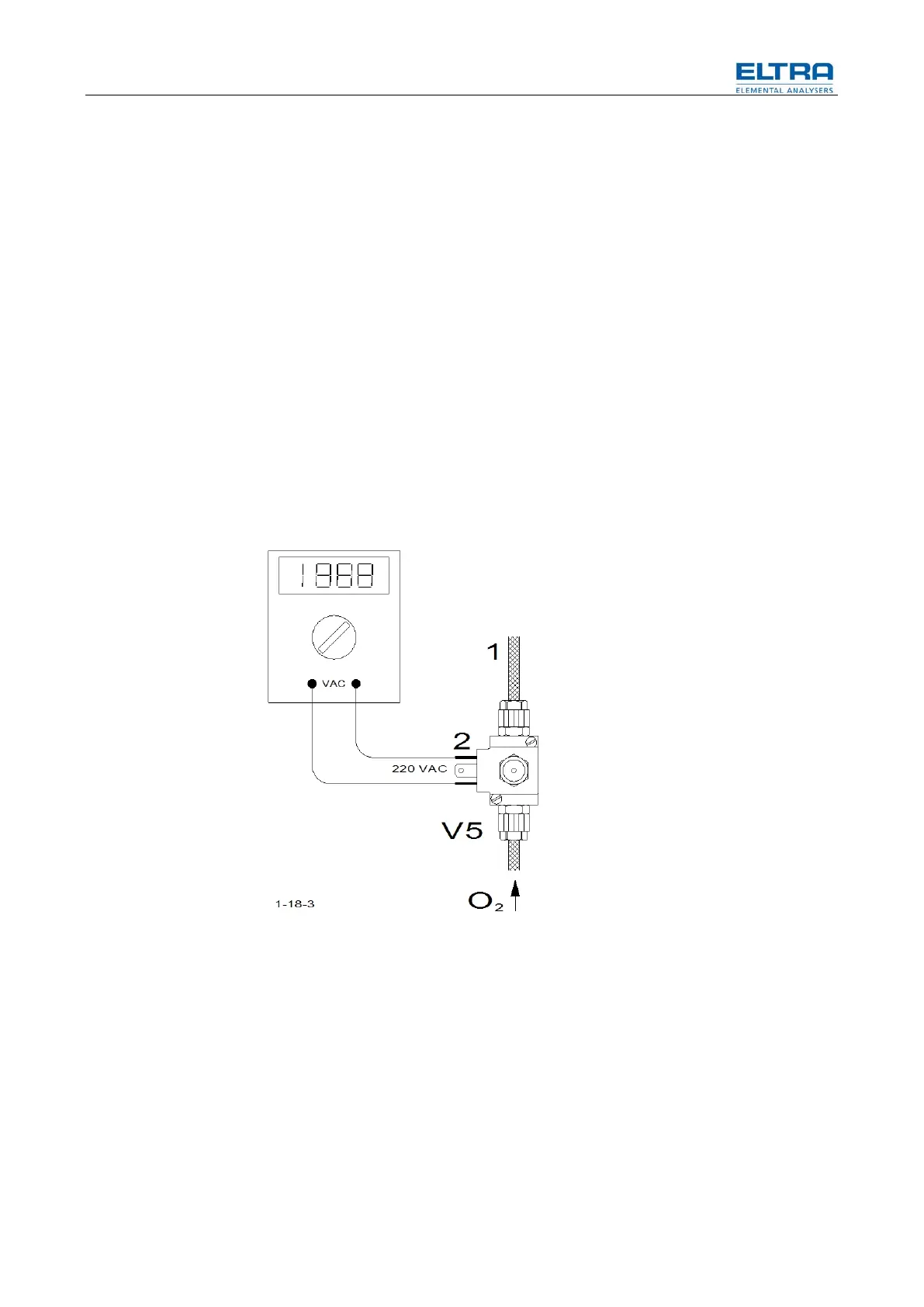

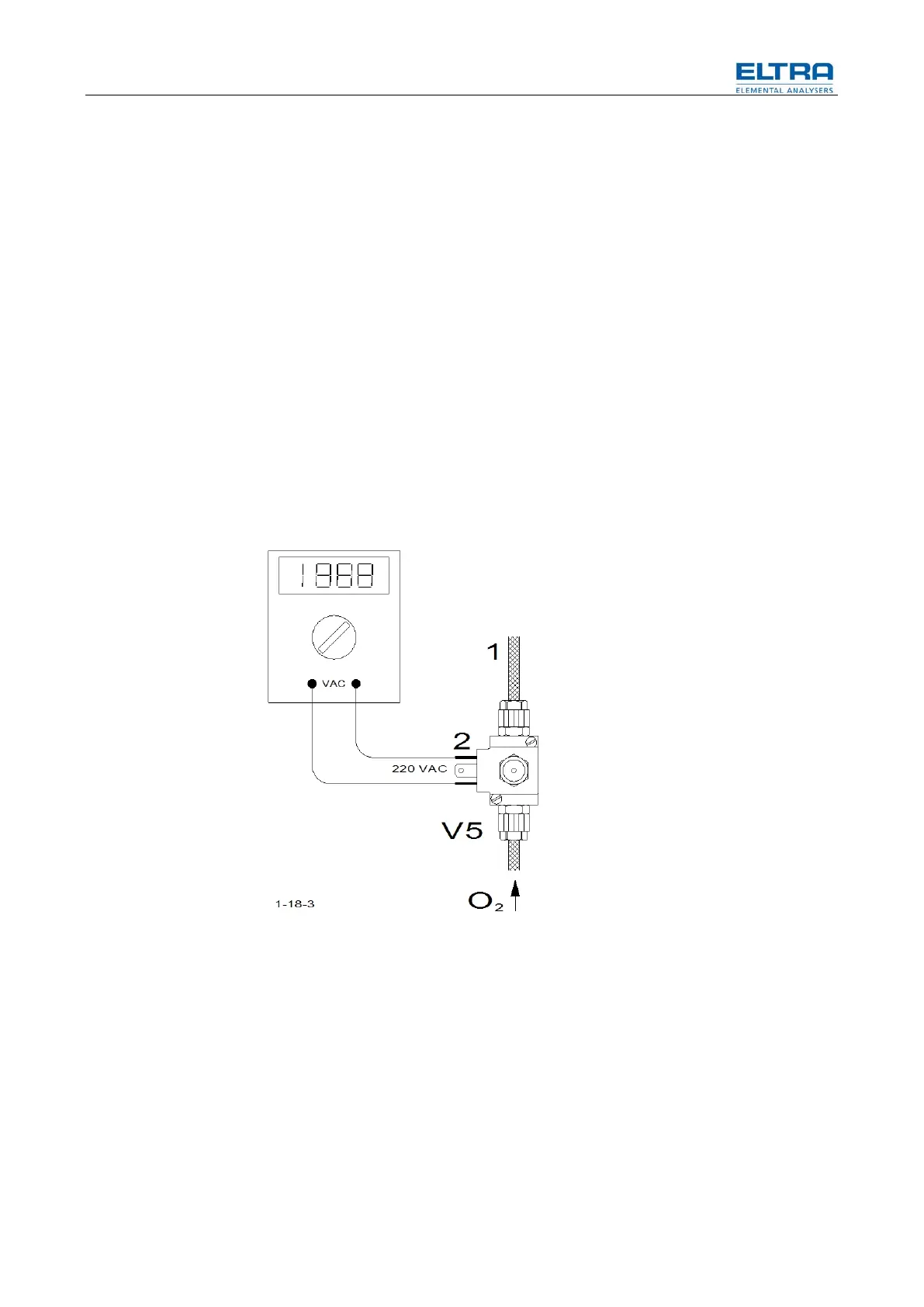

3.17.3.1 Oxygen solenoid valve (V5) may be defective

• Open the left-side panel of the analyzer.

• Unscrew the upper tube (1). The oxygen should rush out when the power

switch is set to pos. 2.

If not:

– There may be no oxygen supplied.

Fig. 35: terminal of the solenoid coil

– 220V AC is not measured on the terminal (2) of the solenoid coil.

– The solenoid valve is clogged.

• Clean the solenoid valve.

If the fault is still present, then:

• Switch off the power, (set the power switch to position 0)

• Pull out the socket (2) from the coil and measure the coil resistance. 3.3K

is normal.

Loading...

Loading...