CG Drives & Automation 01-7492-01r1 Functional description 127

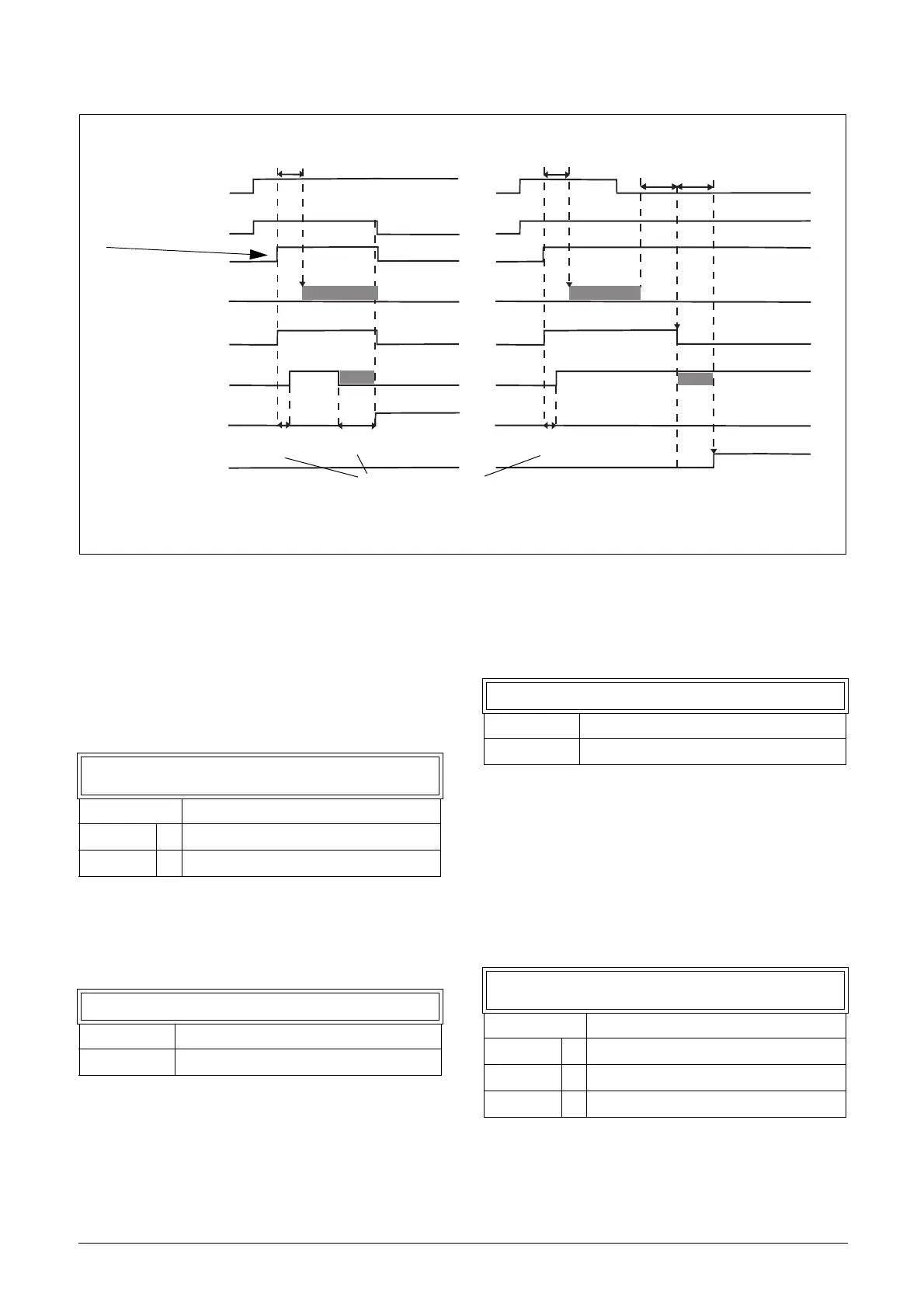

Fig. 102 Principle of Brake operation for fault during run and during stop.

DC Hold [33J]

This function makes it possible to apply a DC-voltage to the

motor at zero speed. This provides a (low) holding torque.

This function is only available in speed mode.

DC Hold [33J1]

Enabling of DC hold functionality.

DC Holding Speed [33J2]

Select the speed at which DC hold is released / enabled.

DC hold is activated if both the speed and the speed

reference is below this value.

DC Holding Current [33J3]

Select the applied DC hold current in percent of nominal

motor current.

Start Vector [33K]

Select the voltage vector applied at start. The start vector is

normally in the direction of the U-phase. It is also possible

to sequentially select different start vectors each start. This

can be advantageous as it distributes the wear more evenly

between different IGBTs. In particular if DC-start is used.

The start vector may also be selected based on the encoder

position (when applicable).

Brake warning

Brake Trip

Brake acknowledge

Brake relay

Speed>0

Torque

Running

Start

During run

During stop

Brake

<33H

33H

<33H

Brake

Brake wait

time

Brake engage

time

33F

33E

33C

33C

release time

release time

Brake Fault trip time

*

**

* Memorized load torque level, if function activated with parameter [33I] Release Torque.

** Time for operator to set down the load.

33J1 DC Hold

Default: Off

Off 0

On 1

33J2 DC Hold Spd

Default: 10rpm

Range: 0 - 250 rpm

33J3 DC Hold Cur

Default: 30 %

Range: 0 - 100 %

33K Start Vector

Default: Normal (U)

Normal (U) 0 U-phase

Sequence 1 Sequentially select different vectors

Encoder 2 Based on encoder position

Loading...

Loading...