Proline Promass E 300 PROFINET Installation

Endress+Hauser 23

DN Ø orifice plate, pipe restriction

[mm] [in] [mm] [in]

8 ³⁄₈ 6 0.24

15 ½ 10 0.40

25 1 14 0.55

40 1½ 22 0.87

50 2 28 1.10

80 3 50 1.97

Orientation

The direction of the arrow on the sensor nameplate helps you to install the sensor

according to the flow direction (direction of medium flow through the piping).

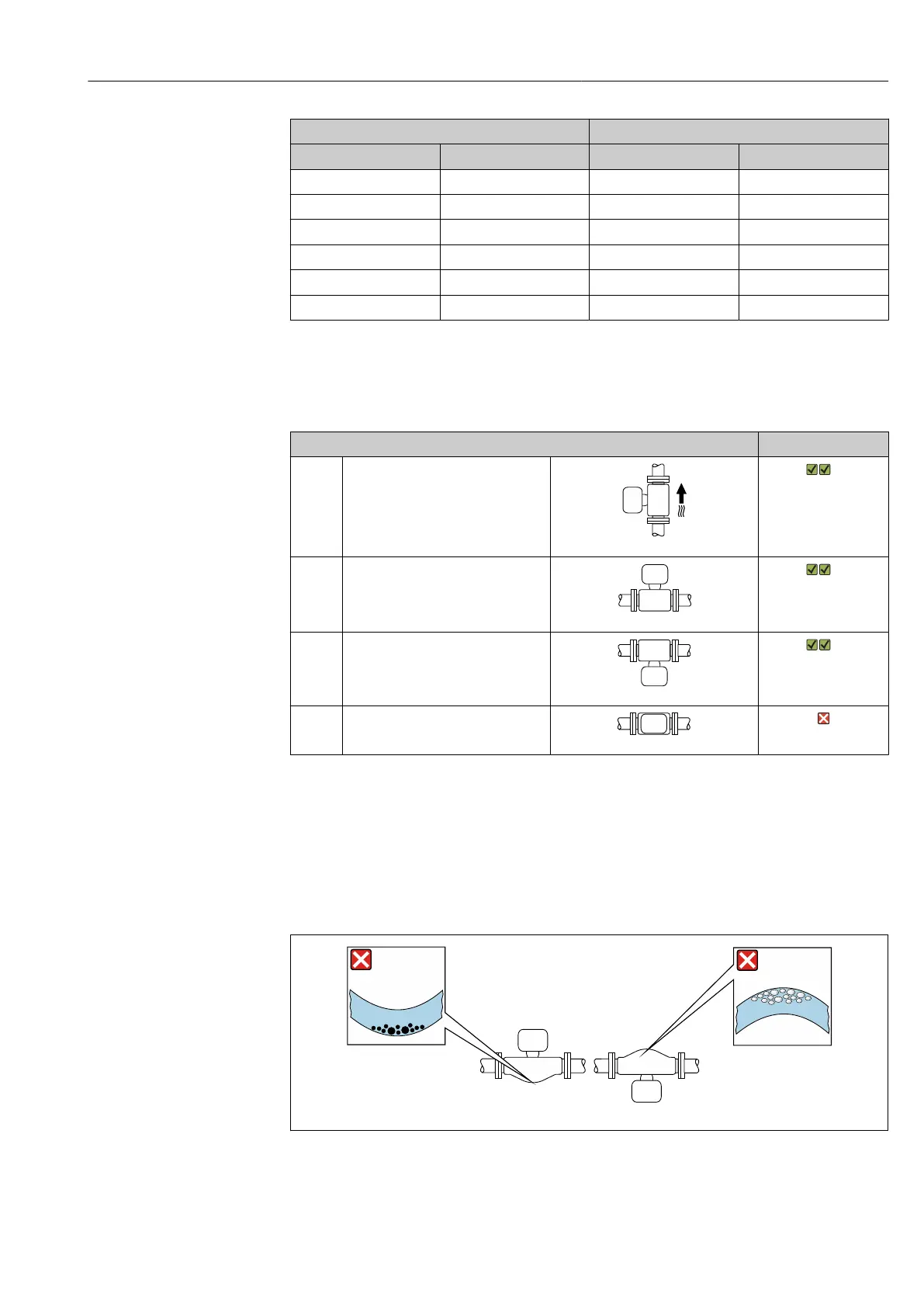

Orientation Recommendation

A Vertical orientation

A0015591

1)

B Horizontal orientation, transmitter at

top

A0015589

2)

Exceptions:

→ 6, 23

C Horizontal orientation, transmitter at

bottom

A0015590

3)

Exceptions:

→ 6, 23

D Horizontal orientation, transmitter at

side

A0015592

1) This orientation is recommended to ensure self-draining.

2) Applications with low process temperatures may decrease the ambient temperature. To maintain the

minimum ambient temperature for the transmitter, this orientation is recommended.

3) Applications with high process temperatures may increase the ambient temperature. To maintain the

maximum ambient temperature for the transmitter, this orientation is recommended.

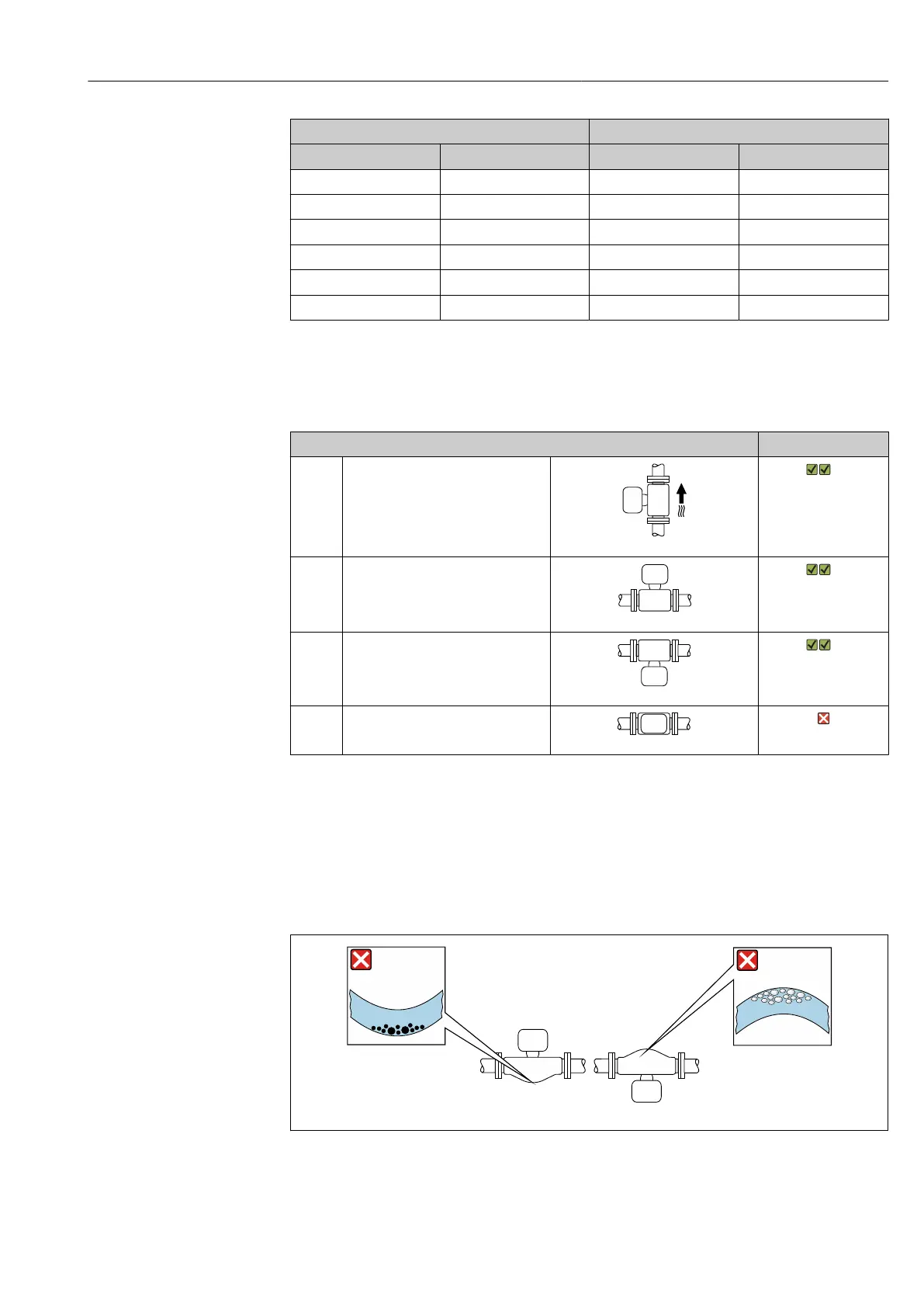

If a sensor is installed horizontally with a curved measuring tube, match the position of the

sensor to the fluid properties.

A0028774

6 Orientation of sensor with curved measuring tube

1 Avoid this orientation for fluids with entrained solids: Risk of solids accumulating.

2 Avoid this orientation for outgassing fluids: Risk of gas accumulating.

Loading...

Loading...