Proline Promass E 300 PROFINET System integration

Endress+Hauser 77

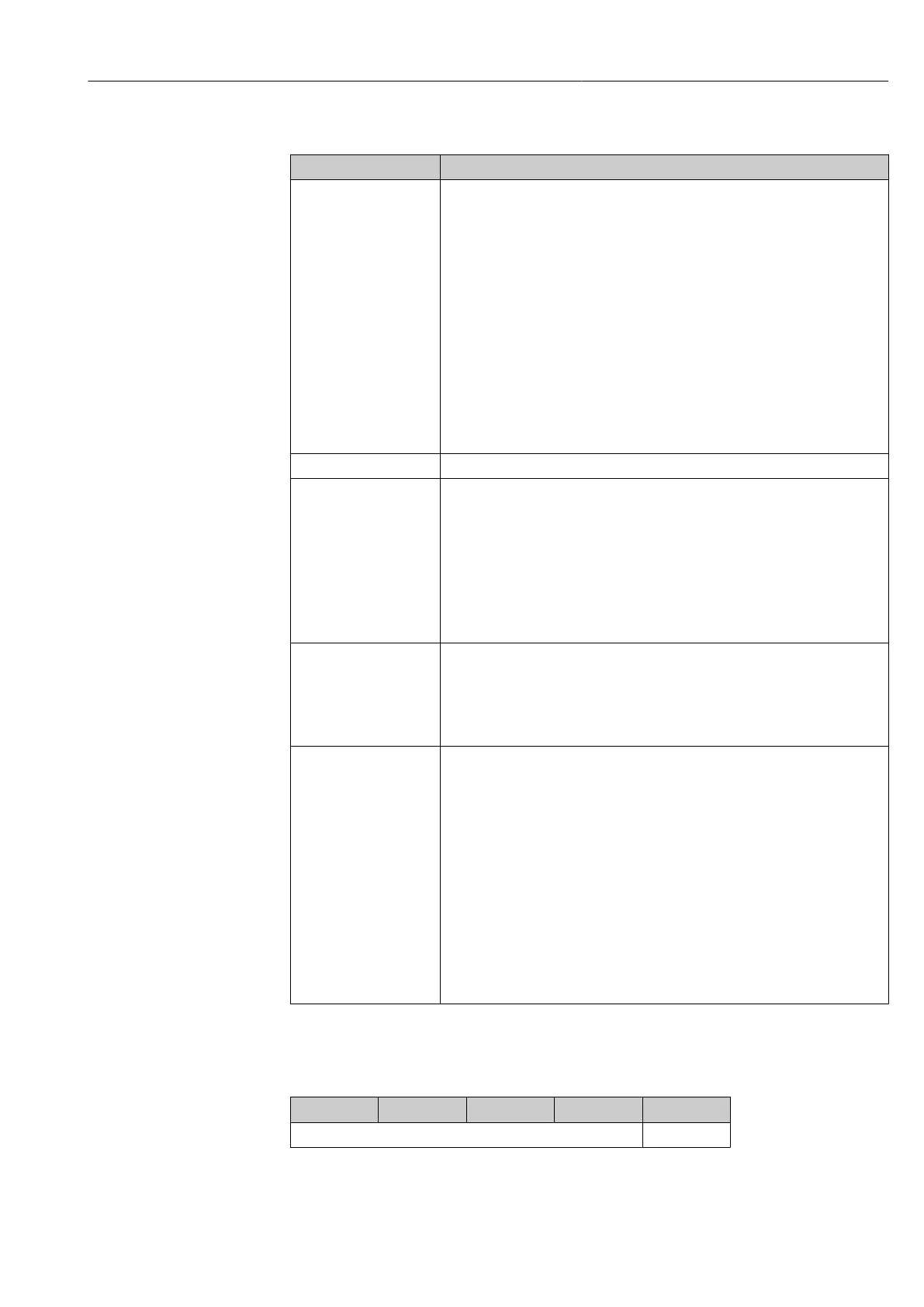

Selection: input variable

Slot Input variables

1 to 14

• Mass flow

• Volume flow

• Corrected volume flow

• Density

• Reference density

• Temperature

• Electronic temperature

• Oscillation frequency

• Frequency fluctuation

• Oscillation damping

• Tube damping fluctuation

• Signal asymmetry

• Exciter current

• Application-specific output 0

• Application-specific output 1

• Index inhomogeneous medium

• Index suspended bubbles

24 to 26 Current input value

1 to 14

Additional input variables with the Heartbeat Verification application package

• Carrier pipe temperature

• Oscillation damping 1

• Oscillation frequency 1

• Oscillation amplitude 0

• Oscillation amplitude 1

• Frequency fluctuation 1

• Tube damping fluctuation 1

• Exciter current 1

• HBSI

1 to 14, 27

Additional input variables with the Concentration Measurement application

package

• Concentration (slot 1 to 14)

• Target mass flow (slot 1 to 14)

• Carrier mass flow (slot 1 to 14)

• Concentration value (slot 27)

1 to 14

Additional input variables with the Petroleum application package

• Oil density

• Water density

• Water cut %

• Oil mass flow

• Water mass flow

• Oil volume flow

• Water volume flow

• Oil corrected volume flow

• Water corrected volume flow

• Replacement reference density

• Gross corrected volume flow

• Gross corrected volume flow, replacement

• Net corrected volume flow

• Net corrected volume flow, replacement

• Sediment and water volume flow

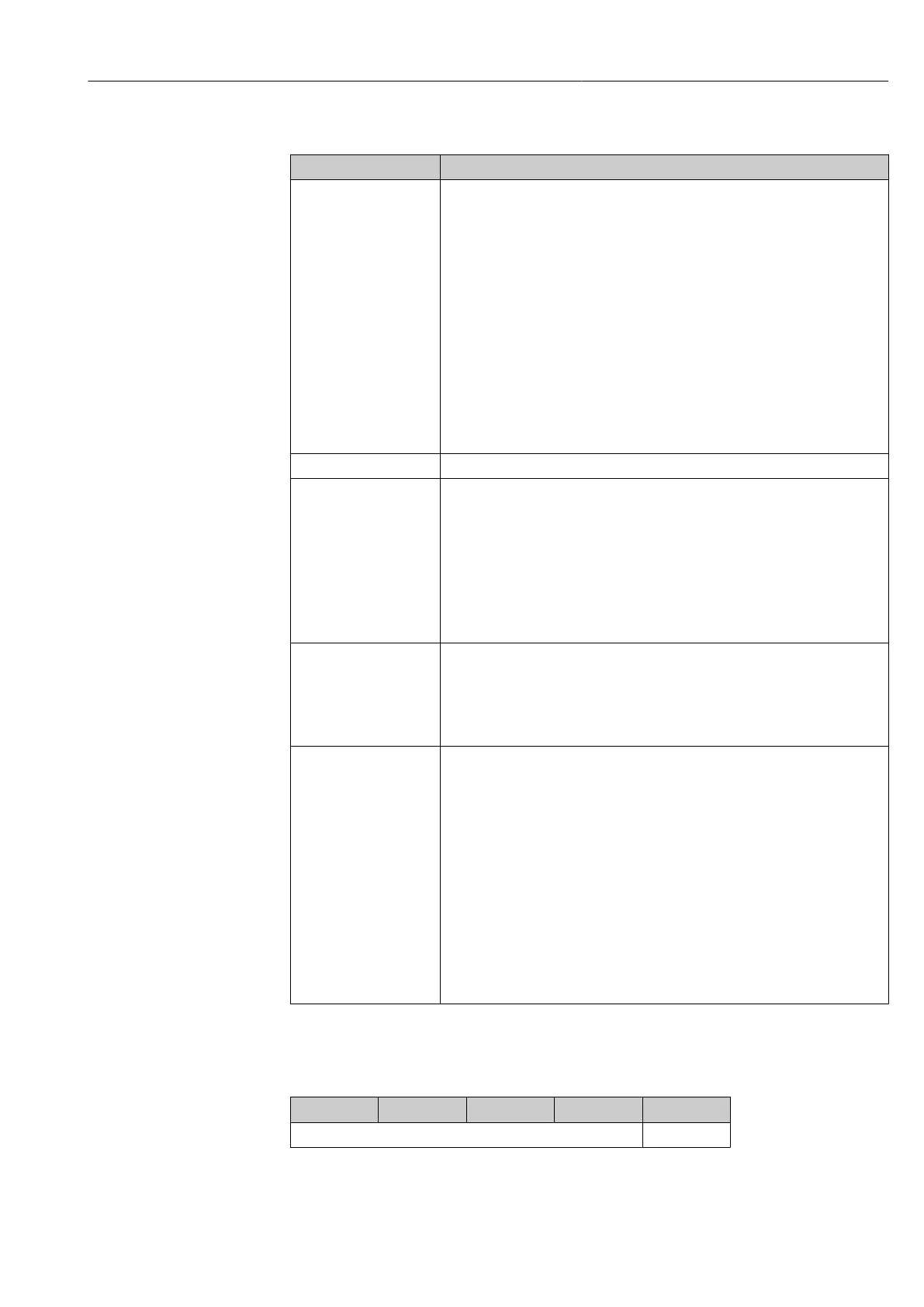

Data structure

Input data of Analog Input

Byte 1 Byte 2 Byte 3 Byte 4 Byte 5

Measured value: floating point number (IEEE 754) Status

1)

1) Status coding → 84

Loading...

Loading...