PROline Prosonic Flow 93 PROFIBUS-DP/-PA 6 Commissioning

Endress+Hauser 103

Control variables for totalizers 1–3 (output data)

These functions allow totalizers 1–3 to be controlled from the automation system.

The following controls are possible: totalizing, resetting, activation of a predefined value,

balancing, totalisation of positive flow only, totalisation of negative flow only and

stopping of totalizing.

Data transfer from the automation system to Prosonic Flow 93 (totalizer controls)

!

Note!

A control variable can be executed through the cyclic data exchange each time the

output byte changes from one bit pattern to any other bit pattern.

It is only possible to preset a predefined totalizer value via the local operation or the

Class 2 master!

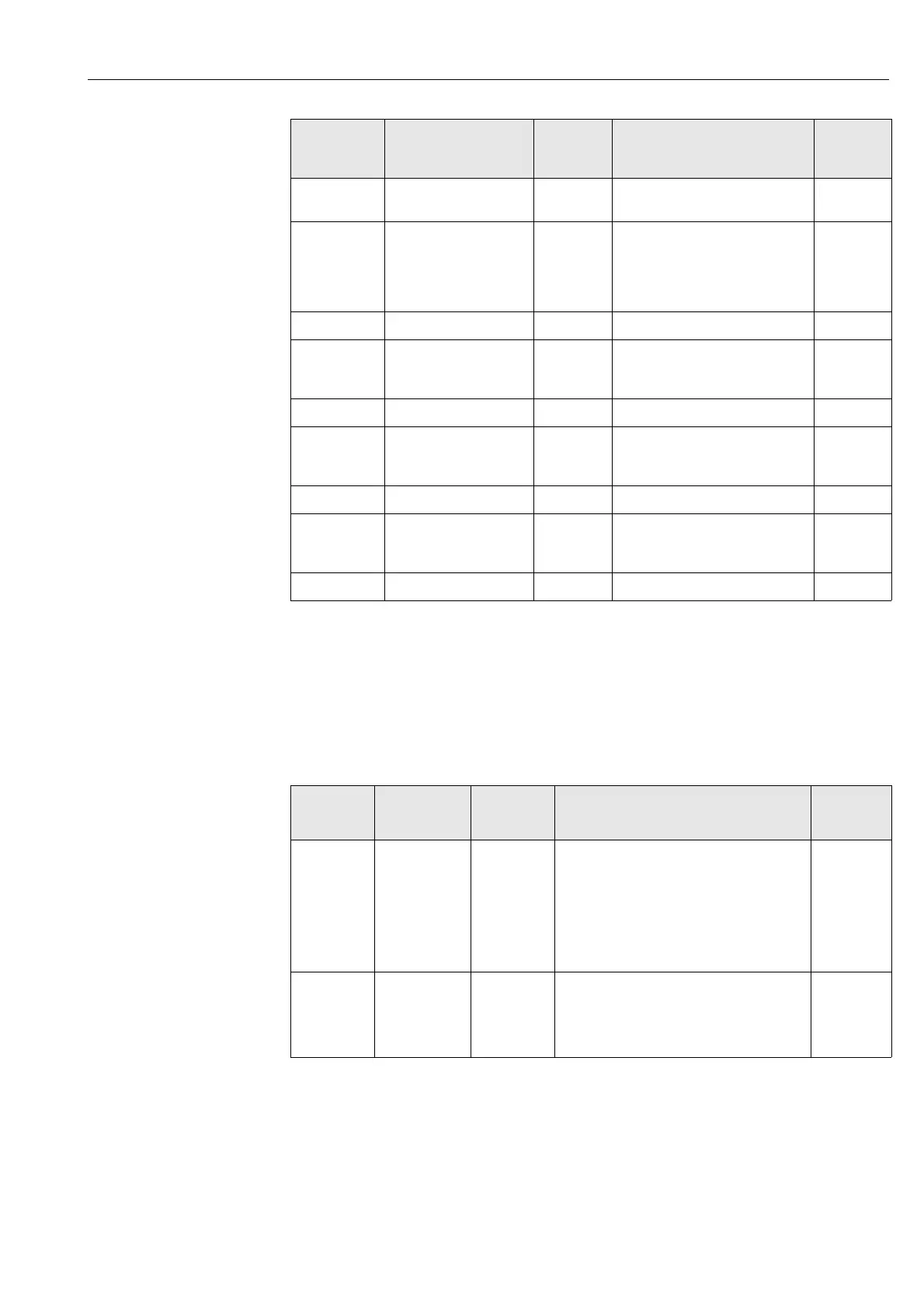

–

Status

volume flow difference

read Status codePage 112 –

–

Average flow velocity

(Channel: 571)

read

32-bit floating point number

(IEEE-754)

Illustrated

Page 99

can be assigned as required!

m/s

– Status flow velocity read Status code

Page 112 –

40, 41, 42, 43 Totalizer 1 read

32-bit floating point number

(IEEE-754)

Illustrated

Page 99

m

3

44 Totalizer 1 status read Status codePage 112 –

45, 46, 47, 48 Totalizer 2 read

32-bit floating point number

(IEEE-754)

Illustrated

Page 99

m

3

49 Totalizer 2 status read Status codePage 112 –

50, 51, 52, 53 Totalizer 3 read

32-bit floating point number

(IEEE-754)

Illustrated

Page 99

m

3

54 Totalizer 3 status read Status codePage 112 –

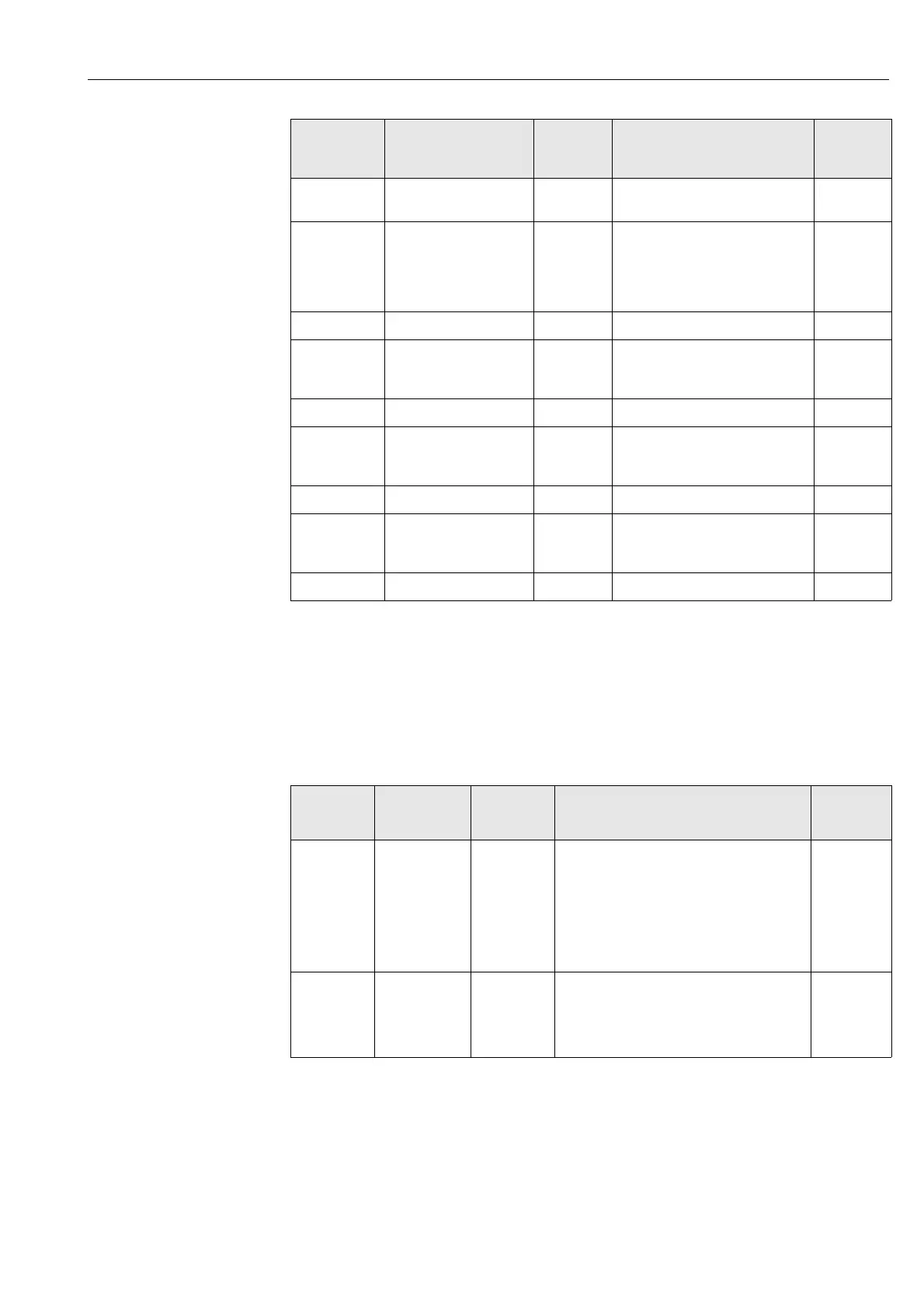

Output

byte

Process

parameter

Access

type

Comment/Control variable Factory

setting

unit

0

2

4

SET_TOT 1

SET_TOT 2

SET_TOT 3

write

write

write

The following control variables can be

entered for totalizers 1–3 using these

parameters.

Control variable for SET_TOT:

0: Totalizing

1: Reset totalizer

2: Preset totalizer

–

1

3

5

MODE_TOT 1

MODE_TOT 2

MODE_TOT 3

write

write

write

Control variable for MODE_TOT:

0: Balancing

1: Only positive flow detection

2: Only negative flow detection

3: Stop totalizing

–

Input

byte

Process parameter Access

type

Comment/Data format Factory

setting

unit

Loading...

Loading...