4 Wiring PROline Prosonic Flow 93 PROFIBUS-DP/-PA

54 Endress+Hauser

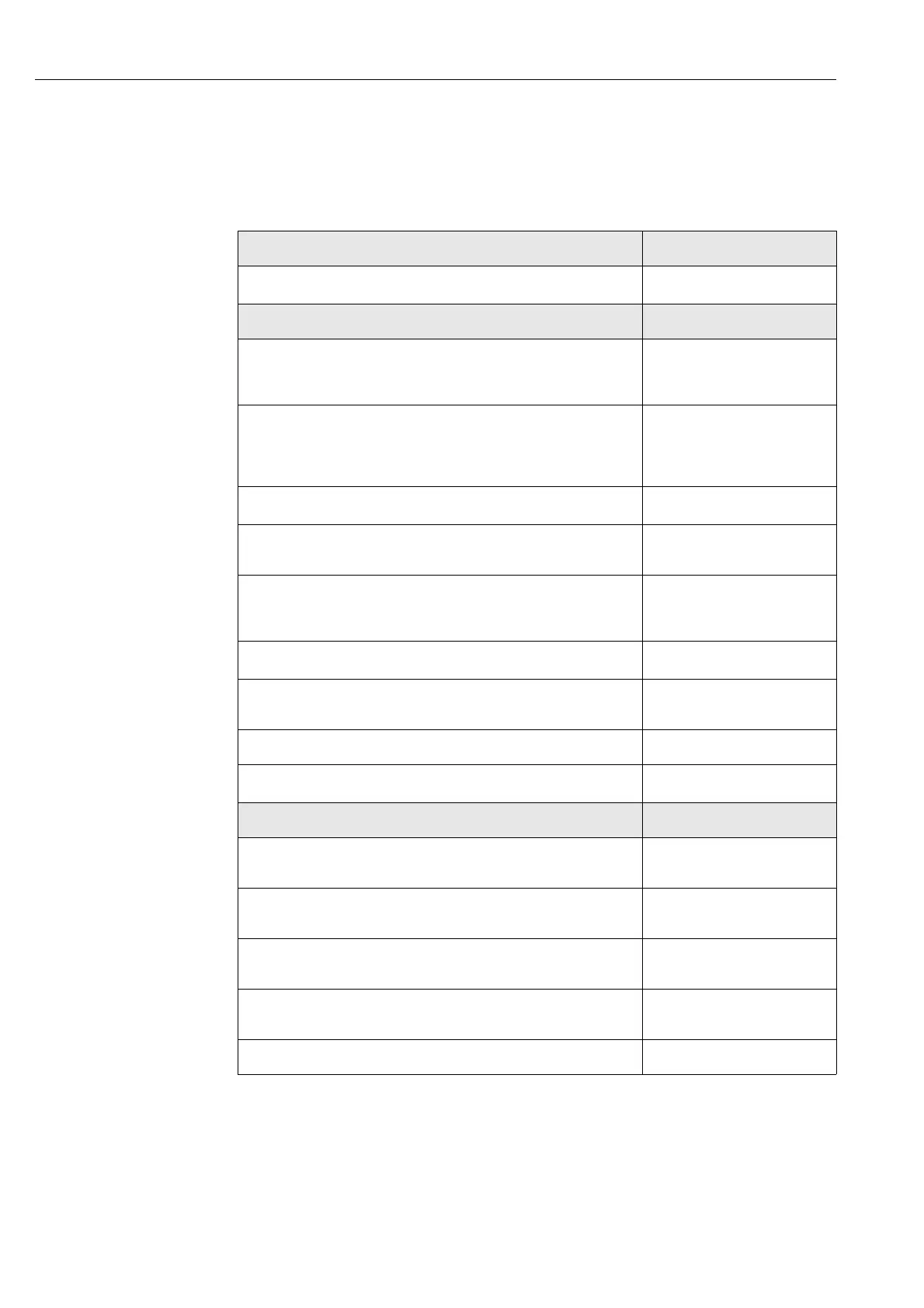

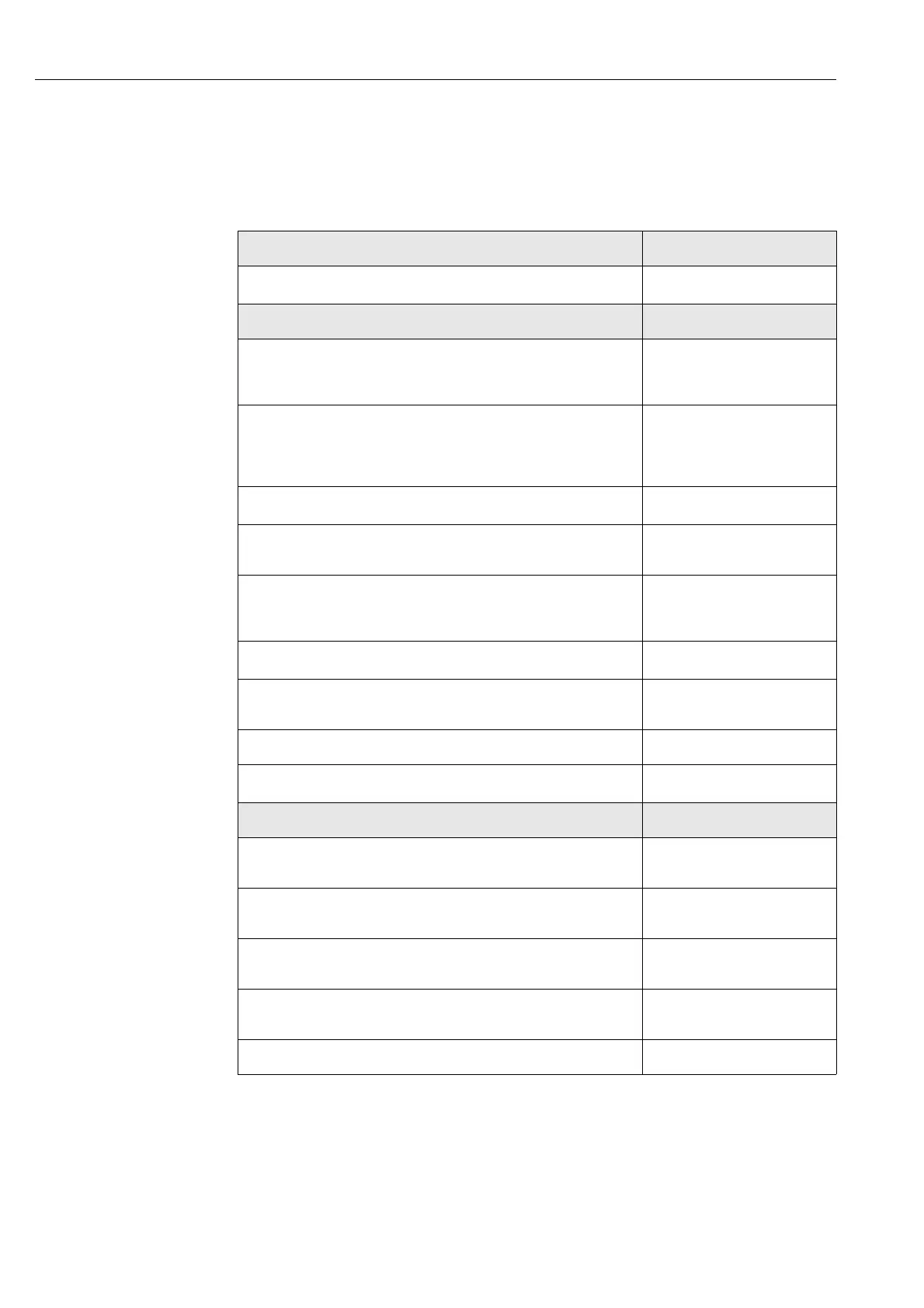

4.6 Post-connection check

Perform the following checks after completing electrical installation of the measuring

device:

Device condition and specifications Notes

Are cables or the device damaged (visual inspection)?

Electrical connection Notes

Does the supply voltage match the specifications on the nameplate? 85...260 V AC (45...65 Hz)

20...55 V AC (45...65 Hz)

16...62 V DC

Do the cables comply with the specifications? PROFIBUS-DP

Page 41

PROFIBUS-PA

Page 44

Sensor cables

Page 47

145

Do the cables have adequate strain relief?

Are the cables correctly segregated by type?

Without loops and crossovers?

Are the power supply and sensor cables correctly connected? See the wiring diagram inside

the cover of the terminal

compartment

Are all screw terminals firmly tightened?

Have the measures for grounding/potential equalisation been

correctly implemented?

see Page 51 ff.

Are all cable entries installed, firmly tightened and correctly sealed? see Page 52

Are all the housing covers installed and tightened?

Electrical connection PROFIBUS-DP/-PA Notes

Are all the connecting components (T-boxes, junction boxes,

connectors, etc.) connected with each other correctly?

–

Has each fieldbus segment been terminated at both ends with a bus

terminator?

–

Has the max. length of the fieldbus cable been observed in

accordance with the PROFIBUS specifications?

PROFIBUS-DP

Page 41 ff.

PROFIBUS-PA

Page 45

Has the max. length of the spurs been observed in accordance with

the PROFIBUS specifications?

PROFIBUS-DP

Page 42

PROFIBUS-PA

Page 45

Is the fieldbus cable fully shielded and correctly grounded? see Page 42

Loading...

Loading...