SS500e/SS2000e/SS3000e Gas Analyzer

1–8 4900002230 rev. D 2-6-20

With the resulting low-noise signal and use of fast post-processing algorithms,

reliable parts per million (ppm) or parts per billion (ppb) detection levels are

possible (depending on target and background species) at real-time response

rates (on the order of 1 second).

All SpectraSensors TDL gas analyzers employ a similar design and hardware

platform. Measuring different trace gases in various mixed hydrocarbon

background streams is accomplished by selecting a different optimum diode

laser wavelength between 700-3000 nm, which provides the least amount of

sensitivity to background stream variations.

Getting Familiar with the Analyzer

SpectraSensors’ SS500e/SS2000e/SS3000e analyzers are typically comprised

of two main enclosures; the analyzer electronics and the sample conditioning

system (SCS), as shown in Figure 1–5. Refer to Appendix A for system

drawings.

On the front panel of the analyzer, the keypad and LCD display serve as the

user interface to the analyzer. Internally, the control electronics drive the laser,

collect the signal, analyze the spectra and provide measurement output

signals.

Housed inside the SCS are the measurement cell and heater along with flow

devices to control flow and pressure for the measurement cell and the bypass

loop.

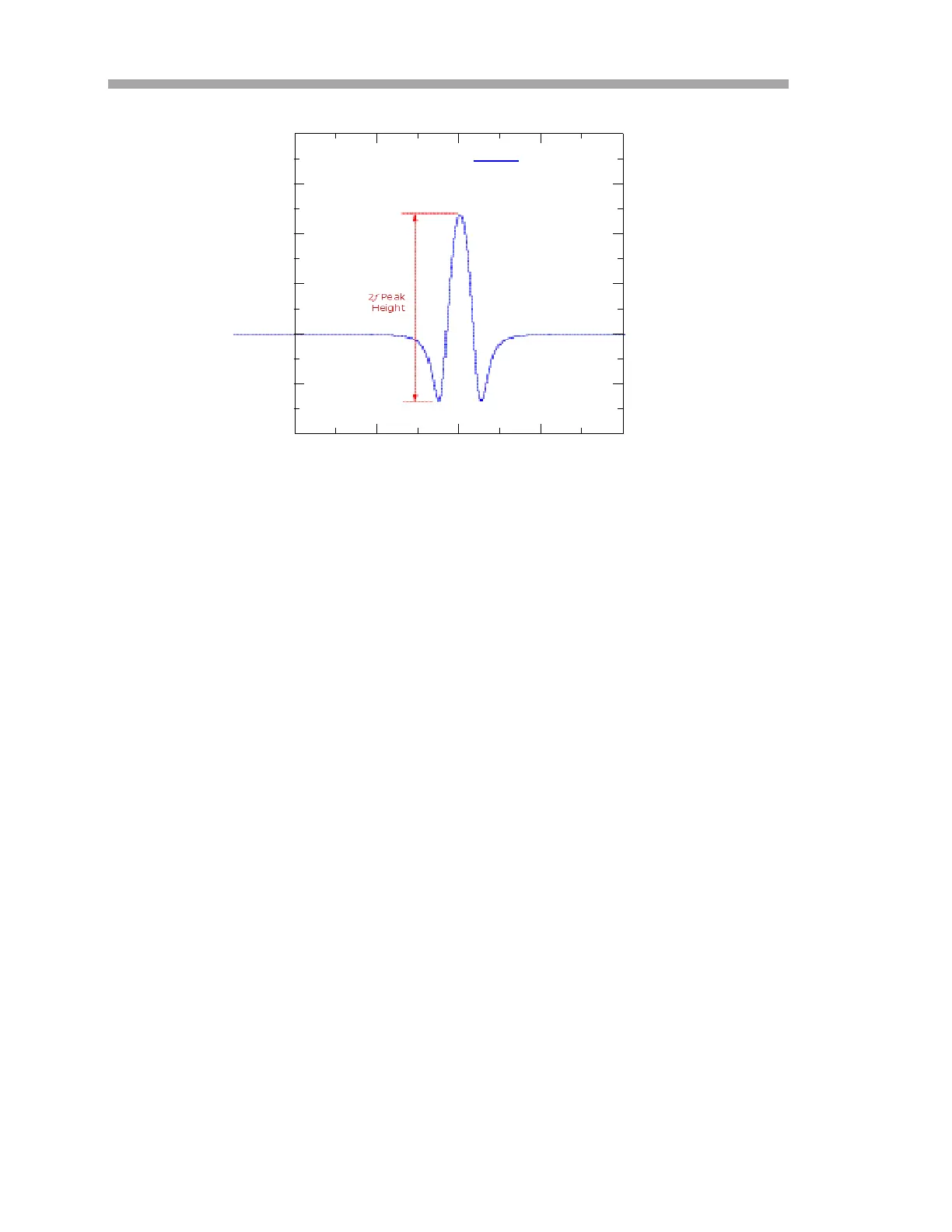

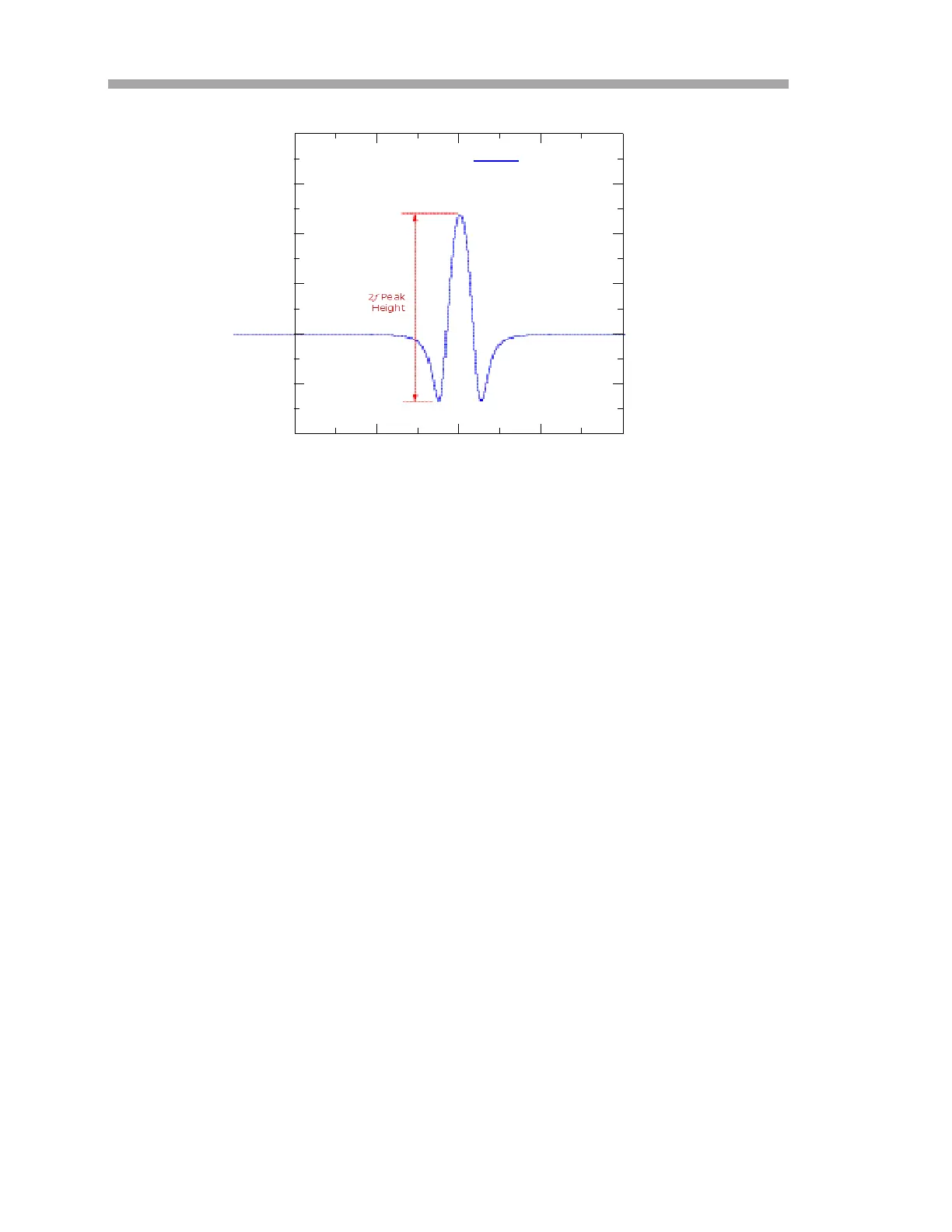

Normalized

2f Signal

Wavelength [a.u.]

Signal [a.u.]

Figure 1–4 Typical normalized 2f signal; species

concentration is proportional to the peak height

Loading...

Loading...