SS500e/SS2000e/SS3000e Gas Analyzers

B–18 4900002230 rev. D 2-6-20

3. Restart the system following the procedure in “Starting up the

SCS” on page 4-6.

Instrument Problems

If the instrument does not appear to be hampered by gas leaks, contamination,

excessive sampling gas temperatures and pressures, or electrical noise, refer

to Table B–1 before contacting your sales representative for service

.

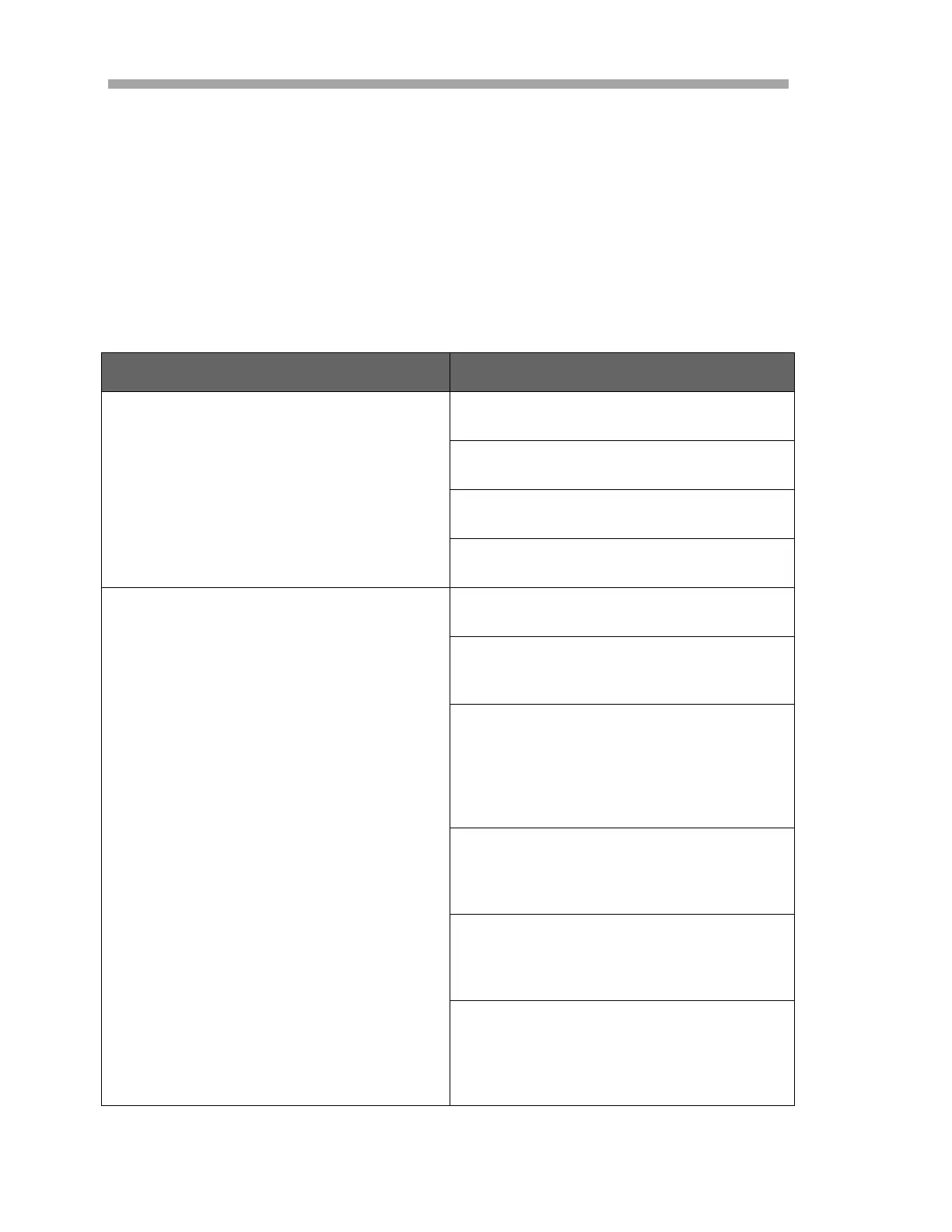

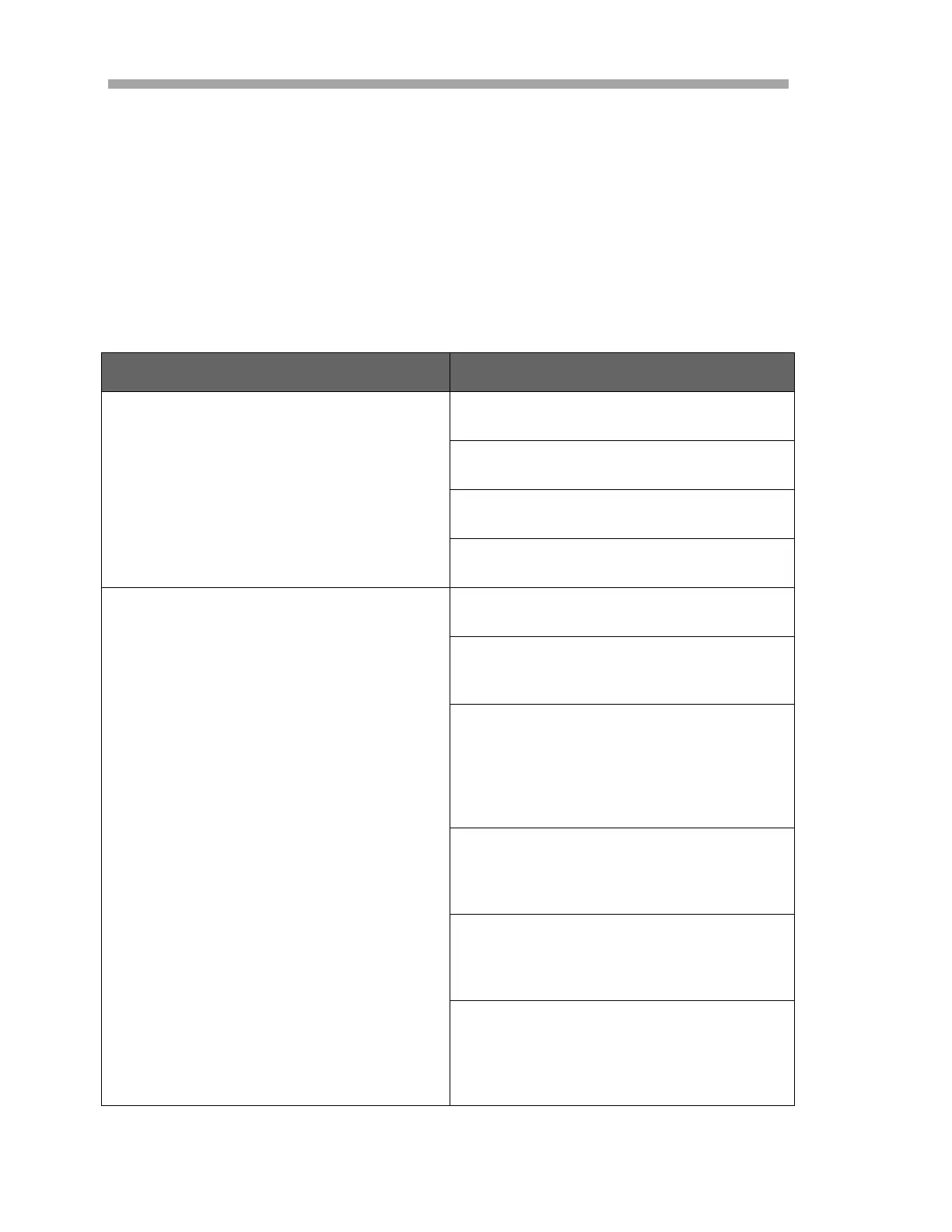

Table B–1 Potential instrument problems and solutions

Symptom Response

Non-Operation (at start up) Is the power connected to both the ana-

lyzer and power source? Is the switch on?

Is the power source good? (100-250 VAC

@ 50-60 Hz, 18-32 VDC).

Check fuse(s). If bad, replace with equiv-

alent amperage, slow-blow fuse.

Refer to“Service Contact” on page

B-23.

Power Fail Error Make sure that the analyzer is protected

from extreme ambient temperature

Possible alignment problem. Contact a

factory sales representative for service

information.

Check the inlet and outlet tubes to see if

they are under any stress. Remove the

connections to the inlet and outlet tubes

and see if the power goes up. Perhaps

the existing tubing needs to be replaced

with stainless steel flexible tubing.

Turn analyzer off and check the hytek

board for loose cables. Do not discon-

nect or reconnect any optical head

cables with the power connected.

Capture diagnostic data and send the

file to SpectraSensors (refer to “To read

diagnostic data with Hyper-Termi-

nal” in the Firmware Operator’s Manual).

Possible mirror contamination issue.

Refer to“Service Contact” on page

B-23. If advised to do so, clean the mir-

rors by following the instructions under

“To clean the mirror” on page B-5.

Loading...

Loading...