REV.-A

A

. . .

-.

—/e

<

Countersink

>

I

Large

Small

I I

\

Carriage

Guide

Shaft B

‘~

Step

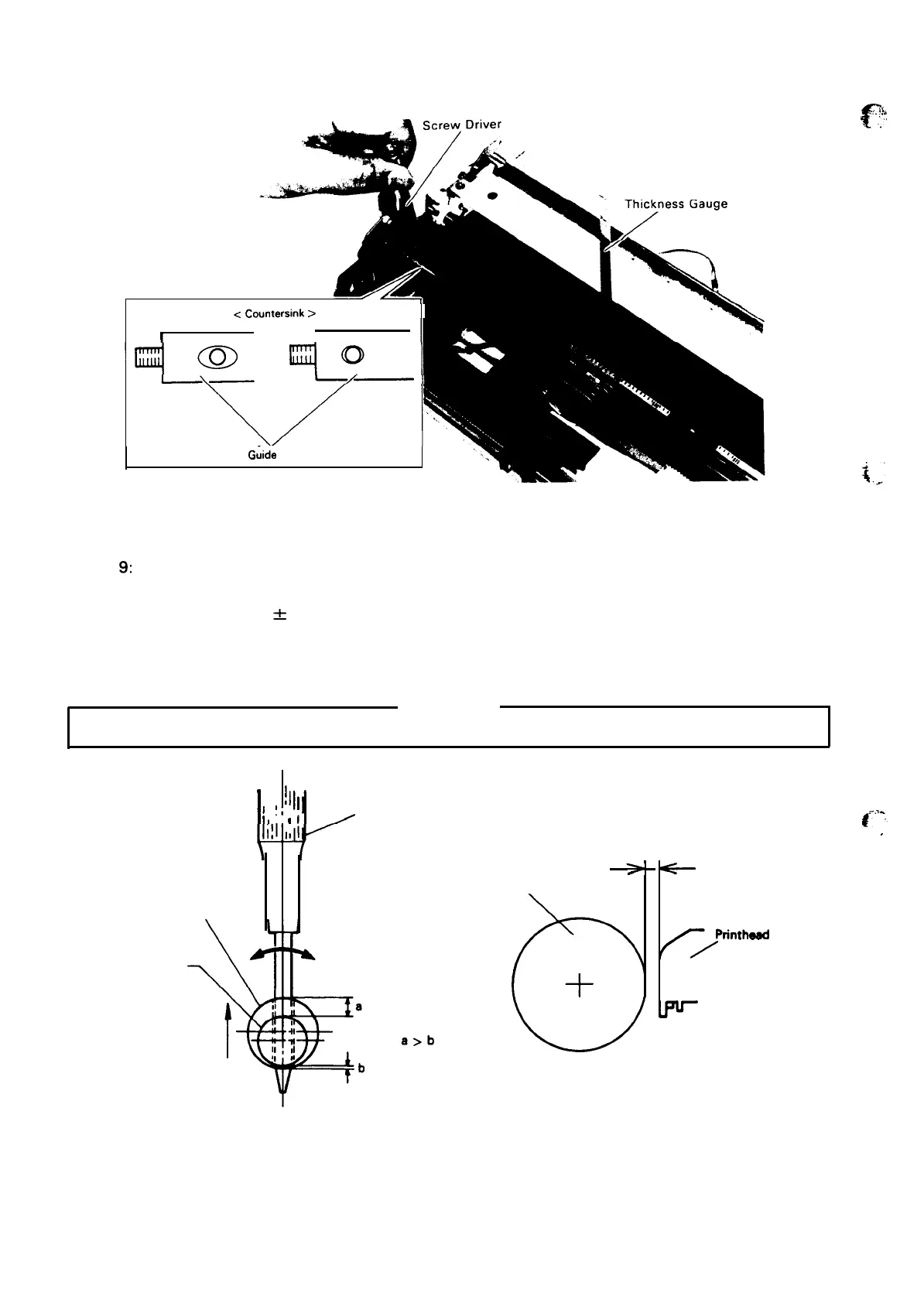

9:

Step 10:

Step 1 1:

Figure 4-54. Platen Gap Adjustment

Set the head adjustment lever at the 2nd position.

Push the paper release lever all the way back.

Gap value: 0.51

f

0.05 mm

Adjust the platen gap using a thickness gauge while rotating carriage guide shaft B in the

direction of the arrow in Figure 4-55.

WARNING

At this time, the paper release lever must be in the friction feed position. (Do not turn it forward.)

carriage

I

l!

I

!1

I

I

1,

1,

I

I

I

~

Screwdriver

Guide Shaft B

‘

screw

up

a>b

Figure 4-55. Eccentric of Carriage Guide Shaft B

4-38

c

.,

.:?!

#-..S,,

..-

. .

.

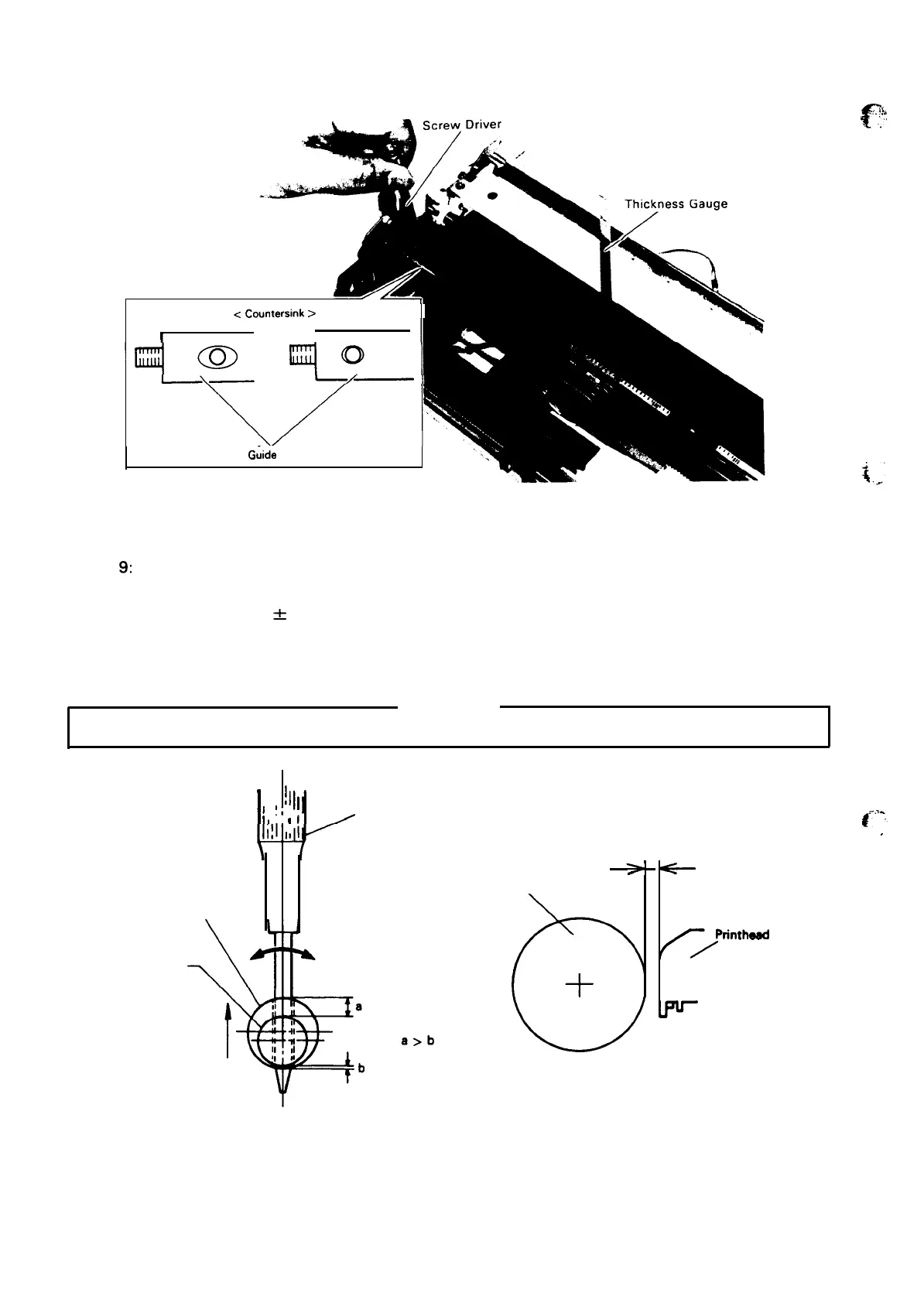

0.51 * 0.05 mm

-

-

Platen

Printhead

</

Figure 4-56. Platen Gap

Loading...

Loading...