2-10 Mechanism Configuration and Operating Principles Rev. A

Confidential

Paper detection mechanism

The paper detection mechanism is located in the paper path. The mechanism provides paper

end detection for the paper roll and semi-automatic loading by detecting presence or absence of

the paper roll when it is inserted. Since the paper detector switch sub assembly is a micro switch,

it is always ON when the paper roll is loaded.

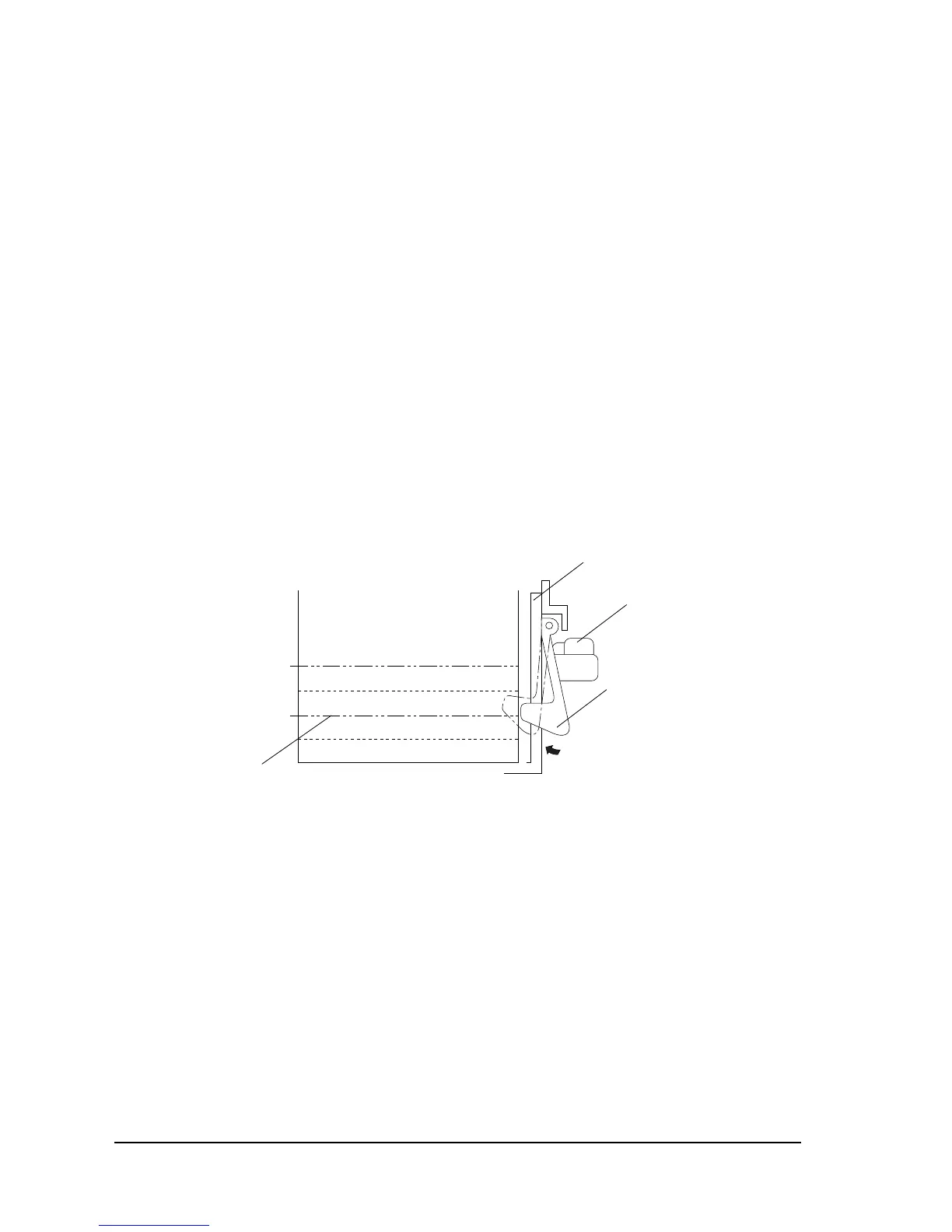

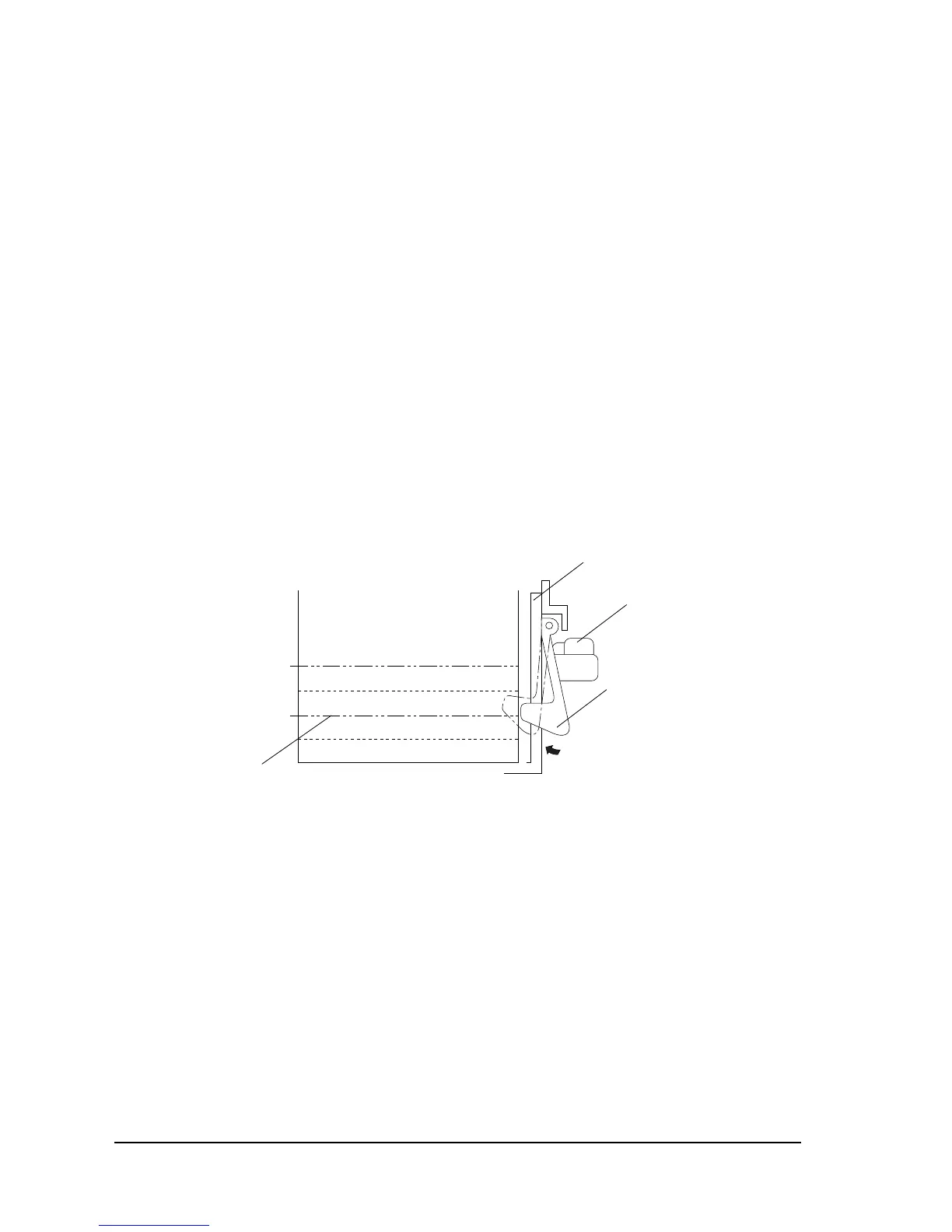

Paper roll near-end detection mechanism (optional)

The near-end detector assembly consists of the near-end detector lever and a microswitch sensor

and is located on the right side of the lower case. This detector senses the amount of paper left

on the paper roll.

The tip of the near-end detection lever is always pressed against the edge of the paper roll by a

spring inside the microswitch. Therefore, when there is a large amount of paper remaining on

the roll, the near-end detection lever is pressed against the side of the paper roll as depicted by

the solid lines in the figure below. This keeps the microswitch turned on. When the amount of

paper left on the roll decreases below a predetermined amount, the tip of the near-end detection

lever no longer presses against the side of the roll and moves in the direction indicated by the

arrow into the hole in the center of the roll core. This turns the microswitch off and generates a

signal indicating that the paper roll is near its end.

Figure 2-13 Paper roll near-end detection mechanism

Auto-cutter mechanism

The printer executes a partial cut (one point left uncut) by driving the cutter motor.

When the motor is energized from the standby state, the wormwheel rotates in the direction

indicated by arrow A through the gears from the motor. The resulting motion of the wheel pin

through arm slot C causes the arm to move in direction B. This, in turn, causes slot D to move the

Paper roll center

Lower case

Microswitch

Near-end

detection lever

Paper roll

Loading...

Loading...