OPERATION

6-3

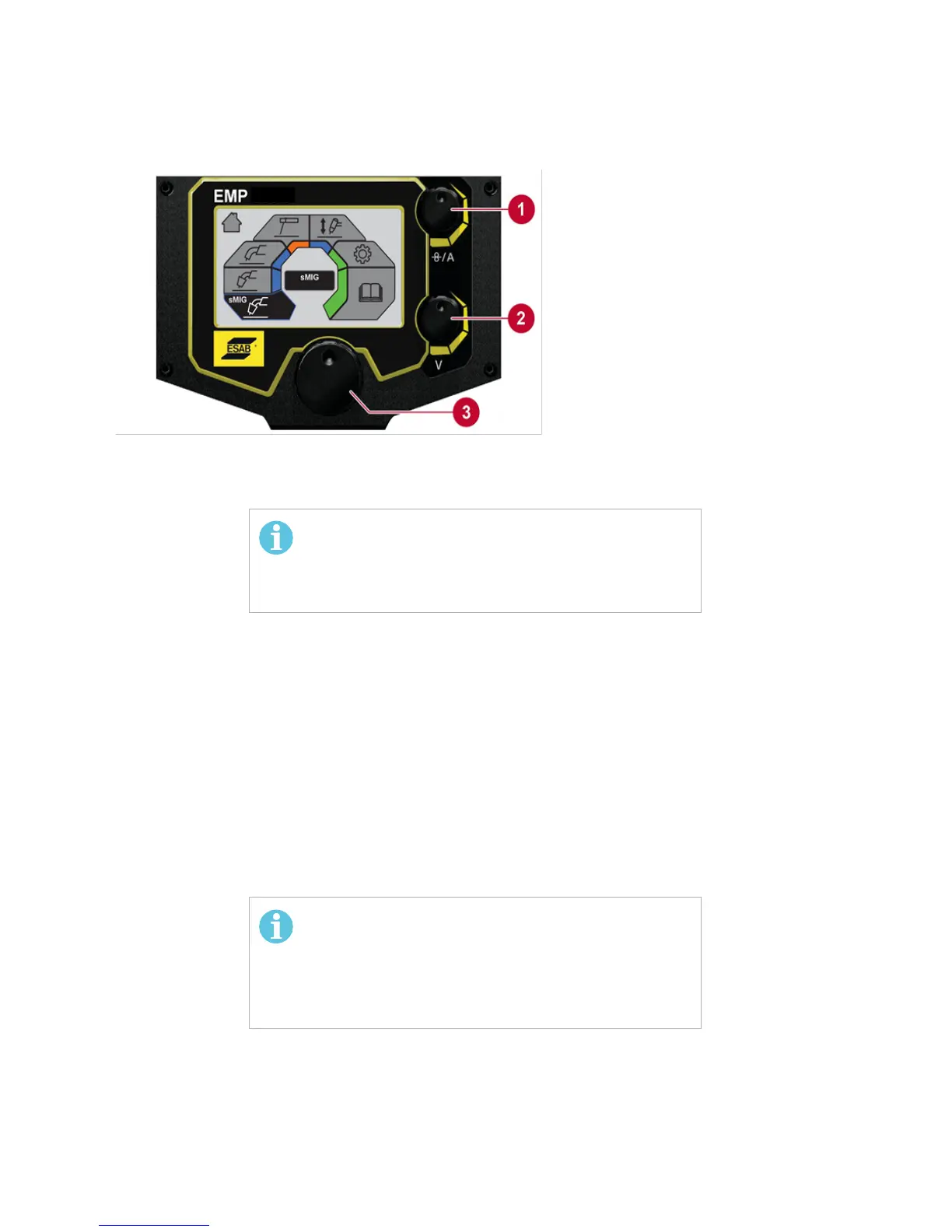

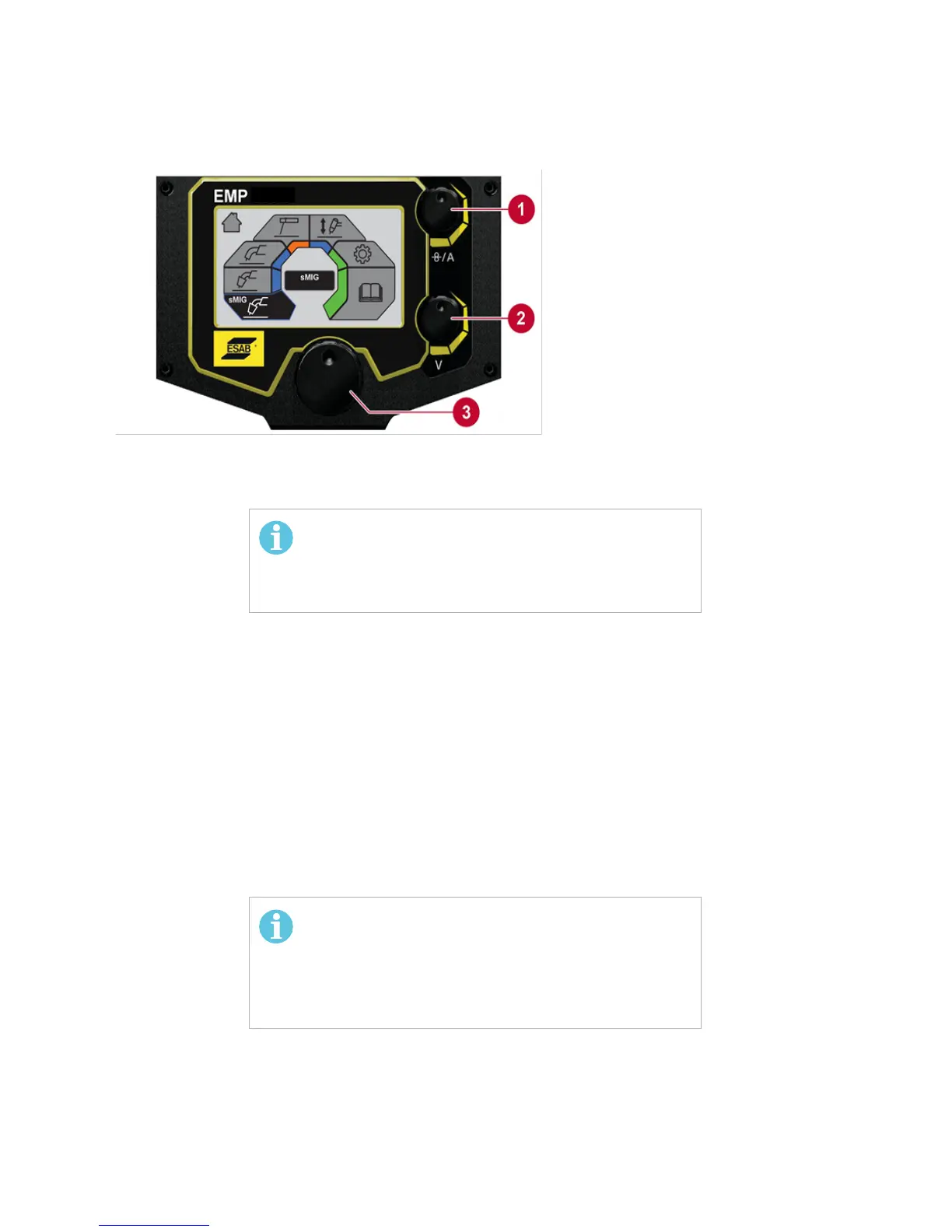

Figure 6-2. Function of User Interface Control Dials

6.2 CONNECTION OF WELDING AND RETURN CABLES

The power source has two outputs for connecting welding and return cables: a negative [-]

terminal (7) and a positive [+] terminal (8) (see Figure 6-1).

6.2.1 FOR MIG/MMA PROCESS

For MIG/MMA process, the output to which the welding cable is connected depends on the

type of electrode. Refer to electrode packaging for information relating to the correct electrode

polarity. Connect the return cable to the remaining welding terminal (9) on the power source.

Secure the return cable's contact clamp to the work piece and ensure that there is good

electrical contact. Connect the torch connector to the Torch connection (6).

1. (U) UPPER CONTROL KNOB:

a. SET CURRENT OUTPUT VALUE

b. SET WIRE FEED SPEED

2. (L) LOWER CONTROL KNOB:

a. MIG VOLTAGE SELECTION

b. SMIG VOLTAGE TRIM

c. MMA MODE: ARC ON/OFF

3. (M) MENU NAVIGATION:

(PUSH TO SELECT)

Lower Control Knob (2), in MMA Mode, Turns Output

Power ON/OFF. When Output Power is ON, background

of display turns Orange. See SECTION 7, CONTROL

MIG Welding Guidance Chart:

The backside of the door on the Bobbin side displays a

MIG welding guidance chart for initial selection of

welding controls. This is intended as a guide for setting

parameters on this machine.

Loading...

Loading...