TROUBLESHOOTING

9-3

Overheating protection trips

frequently.

• Make sure that you are not exceeding the recommended

duty cycle for the weld current you are using.

See section "Duty cycle" in the OPERATION chapter.

• Make sure the air inlets or outlets are not clogged.

• Make sure fans are operating when welding.

9.2 USER INTERFACE (UI) SOFTWARE-DISPLAYED ERROR CODES

The following table exhibits fault codes that may appear to assist in troubleshooting.

Severity Level Meaning (see Severity Level Column in table):

• (C) Critical Service Required - Unit not functional or locked, not recoverable

• (NC) Non-Critical - Service may be desired - unit functional with limited performance

• (W) Warning - Unit functional and will recover on its own

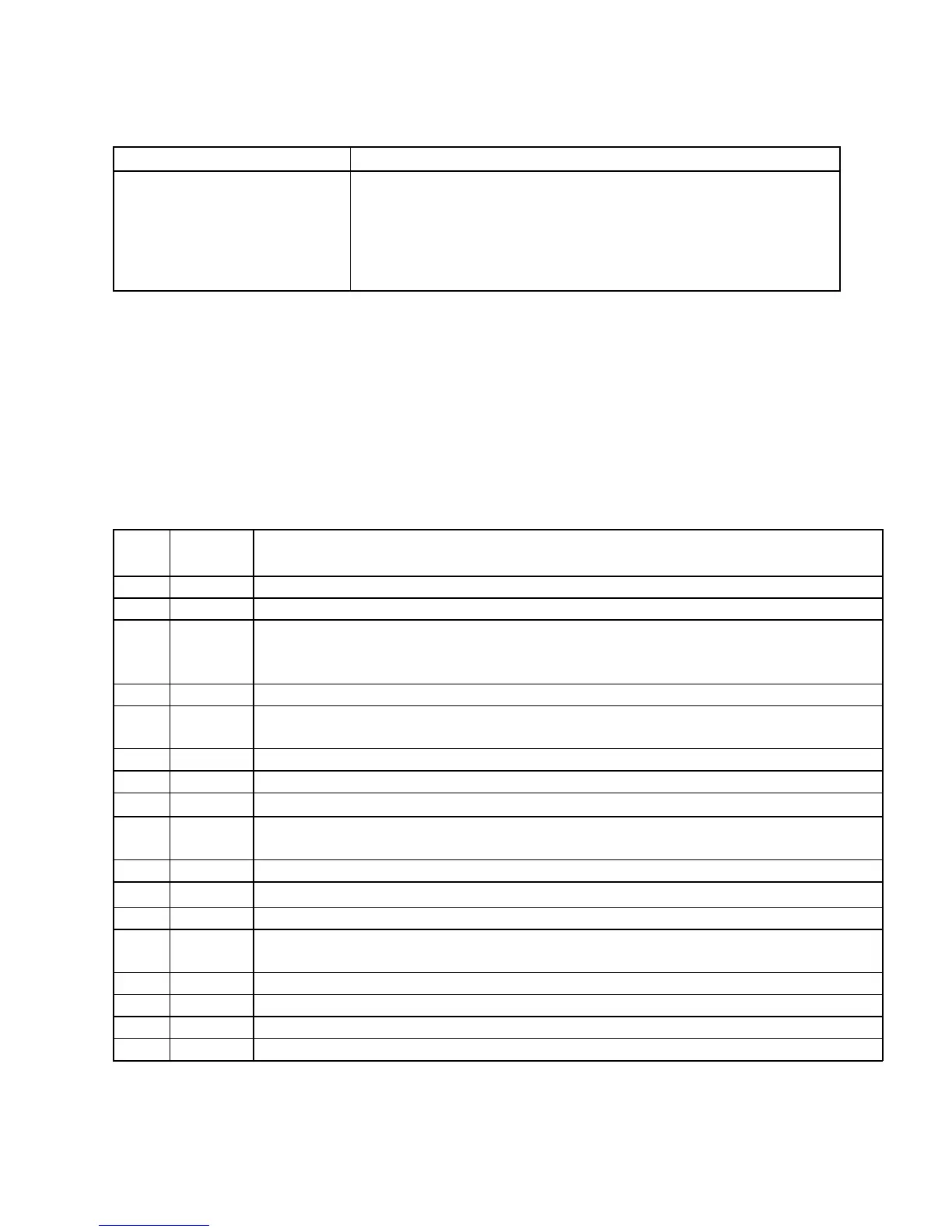

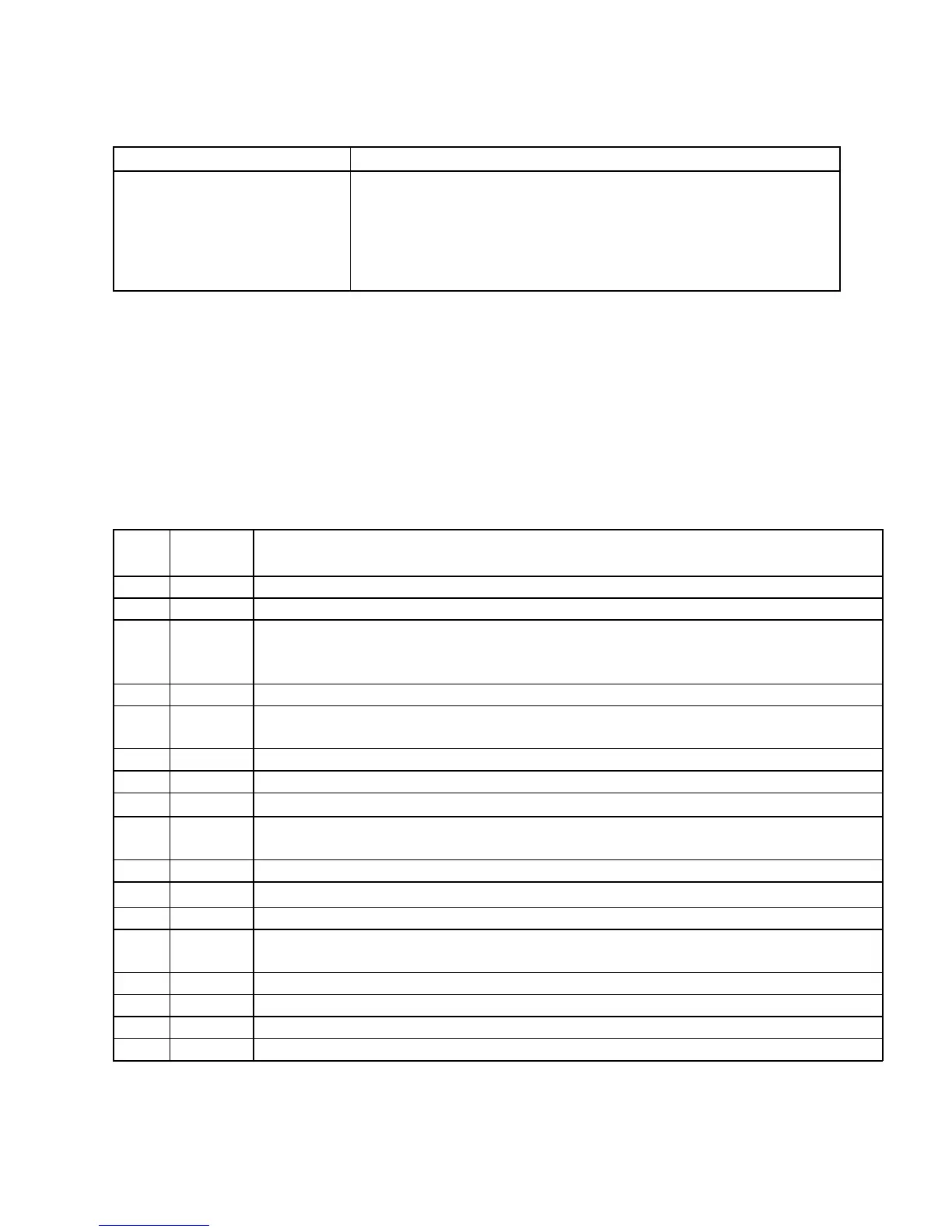

Table 9-2. UI Error Codes

Functional Circuit Failure Explanation

PFC Heatsink, IGBT Heatsink or Main transformer has overheated > 85 C

Output diode Temperature fault, Analog temperature sensor.

Warning - If occurred during load/arc-start, cause is due to low input AC volts - Err009

Critical - If occurred at power-up under no-load condition.

DC Bus (400V) fault droop under load, PFC not supplying 400 to inverter.

Output voltage is above VRD levels when VRD switch is active

OCV error, Output voltage not sensed at Control Board CN1 as expected

Low Voltage Error, AC Mains voltage is less than 108 VAC, this could trip Err 003

User has attempted a parameter or factory reset, and this was not confirmed by the

system.

Communication Link Down, no communication between UI and Ctrl PCB at CN6

Low Internal Power Supply (IPS) Voltage Error, +24V IPS is less than 22VDC

Secondary Current Sensor output not detected at Control PCB CN18

The image read from the flash is corrupted

Failed two attempts of saving user memory to permanent memory in SPI Flash.

Failed two attempts of recovering user memory permanent memory from SPI Flash.

Loading...

Loading...