The machine disperses, de-agglomerates and homogenizes powdered

material to liquid or highly viscous suspensions. At the same time the

product is degassed.

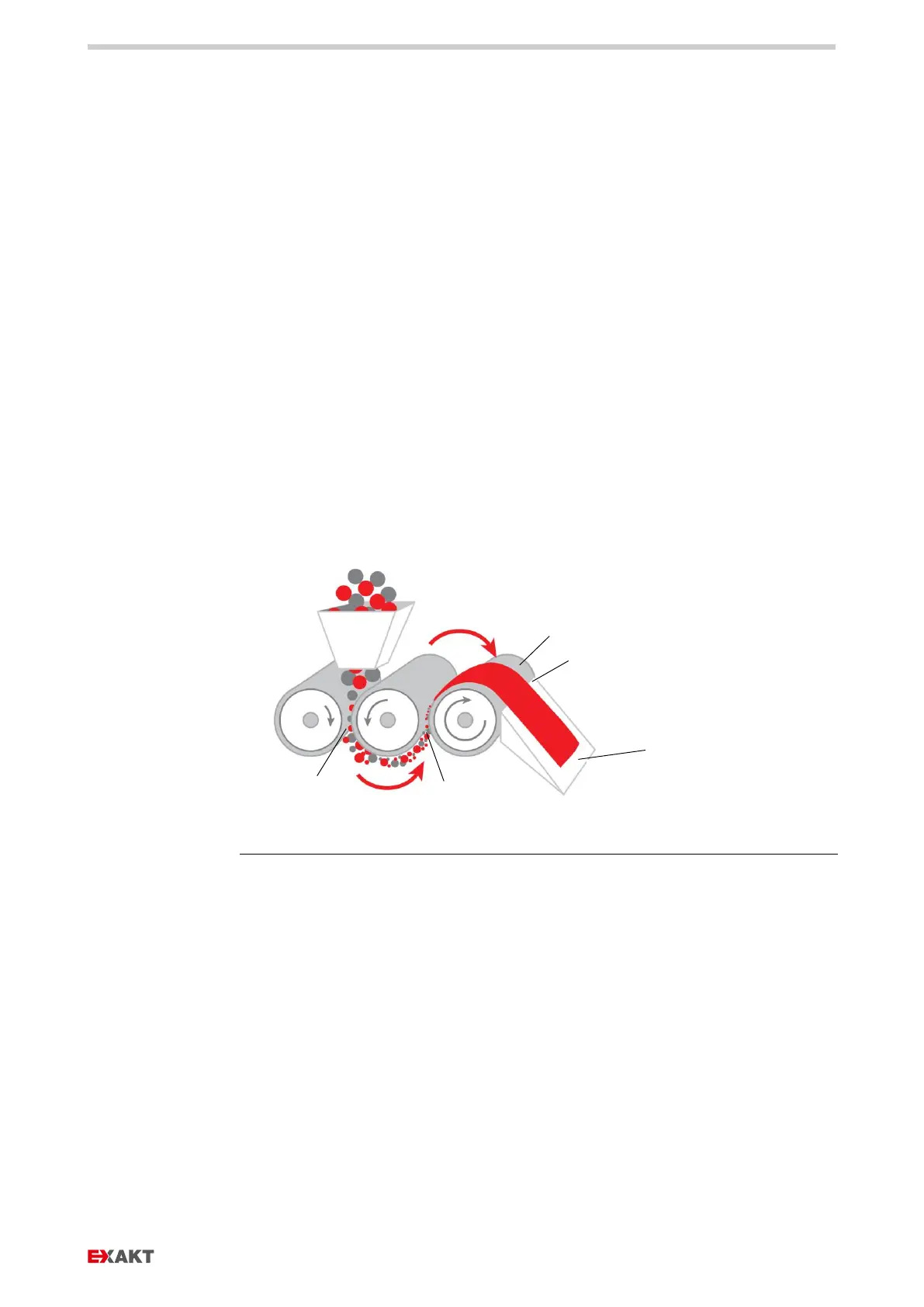

The three rollers rotate reversely with various speeds in a speed ratio of

approx. 1:3:9.

Roller 3 (c) has the highest speed.

The product is supplied into gap 1 (a) where it is pre-dispersed.

Then the product is supplied to gap 2 (b), where the final dispersion takes

place.

The scraper knife (d) scrapes the product from roller 3 (c), and the product

flows off via the scraper socket (e).

The fineness of the final product can be influenced by various gap settings,

speed settings and the number of passes.

Loading...

Loading...