4 Electrical installation

34 Festo – GDCP-CMMP-M0-HW-EN – 1511c – English

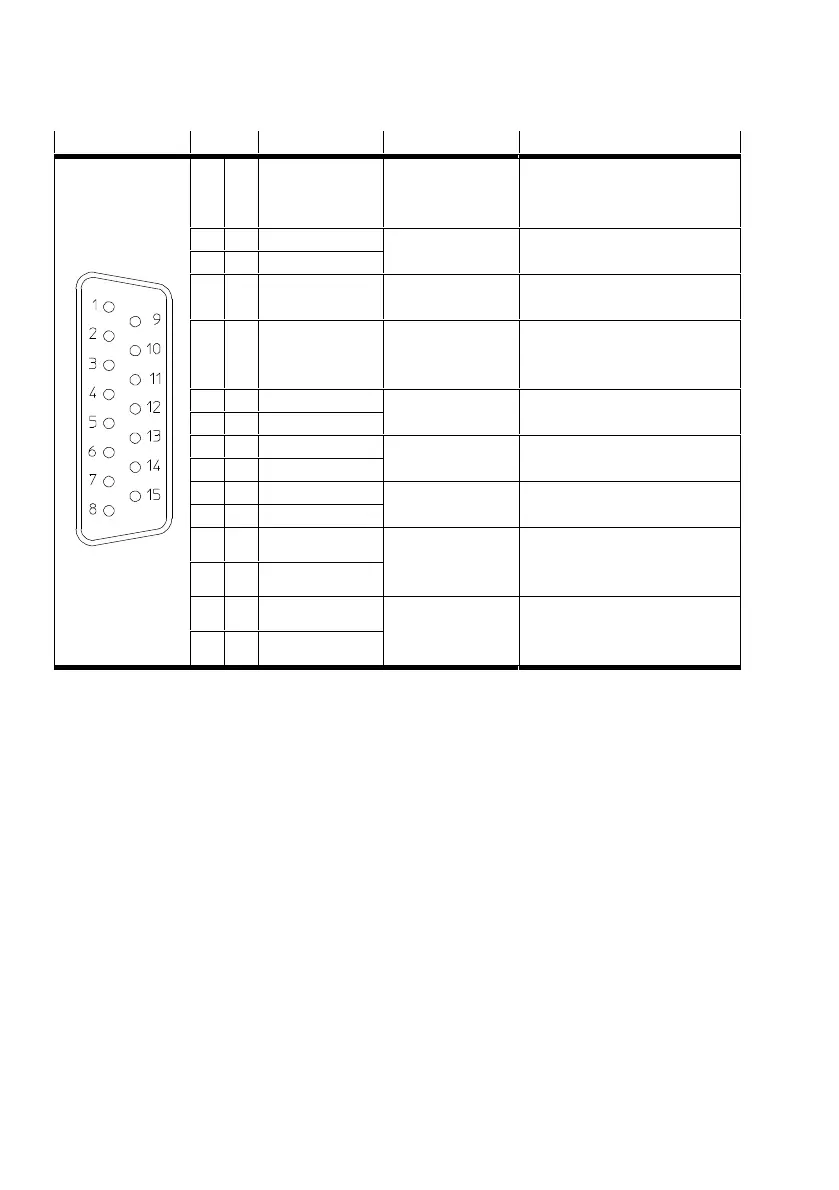

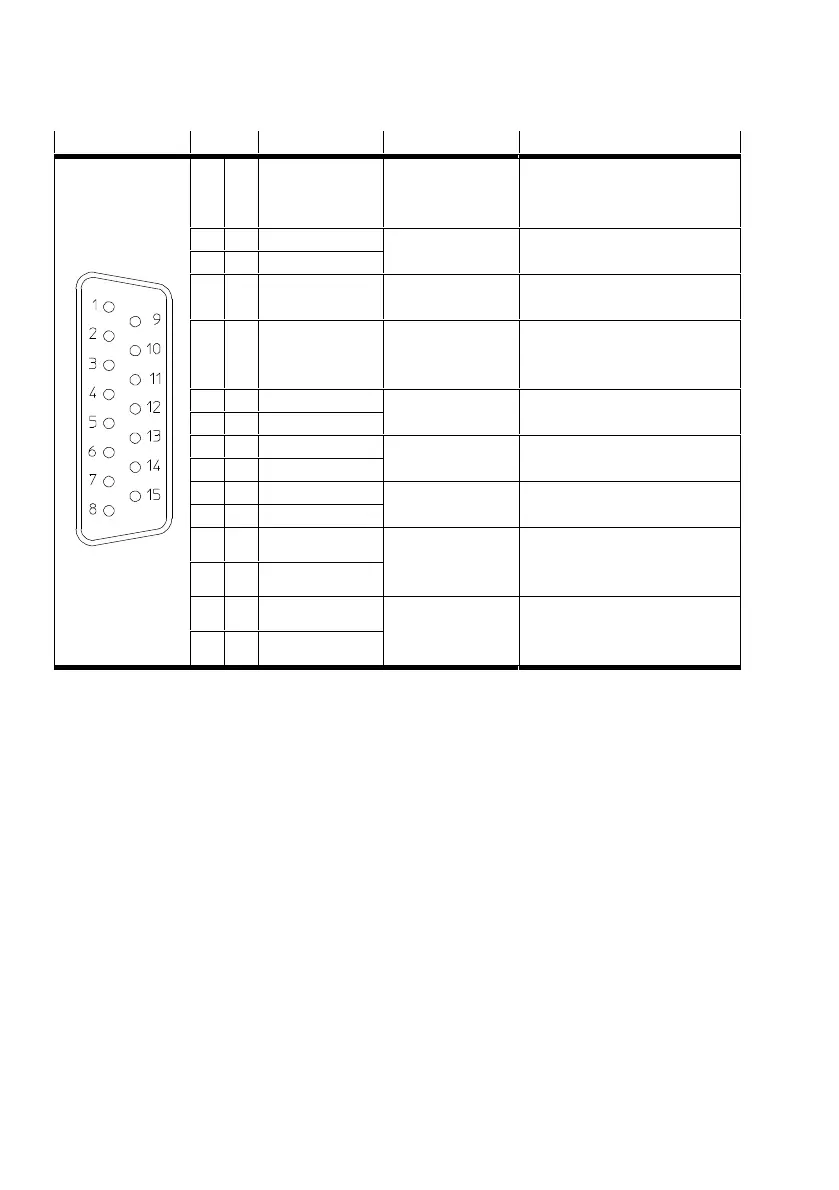

[X2B] Pin no. Designation Value Specification

1 MT+ +3.3 V R

i

= 2 kΩ Temperature sensor, motor

temperature, N/C contact, PTC,

KTY ...

9 U_SENS+ 5 V … 12 V

R

I

L 1 kΩ

Sensor cable for the encoder

supply

2 U_SENS-

10 US 5 V/12 V ±10%

I

max

= 300 mA

Operating voltage for high-res

olution incremental encoder

3 GND 0V Reference potential for en

coder supply and motor tem

perature sensor

11 –

4 –

12 DATA 5 V

SS

R

I

L 120 Ω

Bidirectional RS485 data cable

(differential)

5 DATA#

13 SCLK 5 V

SS

R

I

L 120 Ω

RS485 clock output

(differential)

6 SCLK#

14 COS_Z0 1) 1 V

SS

±10%

R

I

L 120 Ω

COSINE tracking signal

(differential) from high-resolu

tion incremental encoder

7 COS_Z0 1)#

15 SIN_Z0

1)

1 V

SS

±10%

R

I

L 120 Ω

SINE tracking signal

(differential) from high-resolu

tion incremental encoder

8 SIN_Z0 1)#

1) Heidenhain encoder: A=SIN_Z0; B=COS_Z0

Tab. 4.10 Pin assignment: Incremental encoder with serial interface, e.g. EnDat – optional

The outer screening must always be connected to the PE (plug housing) of the motor controller.

Loading...

Loading...