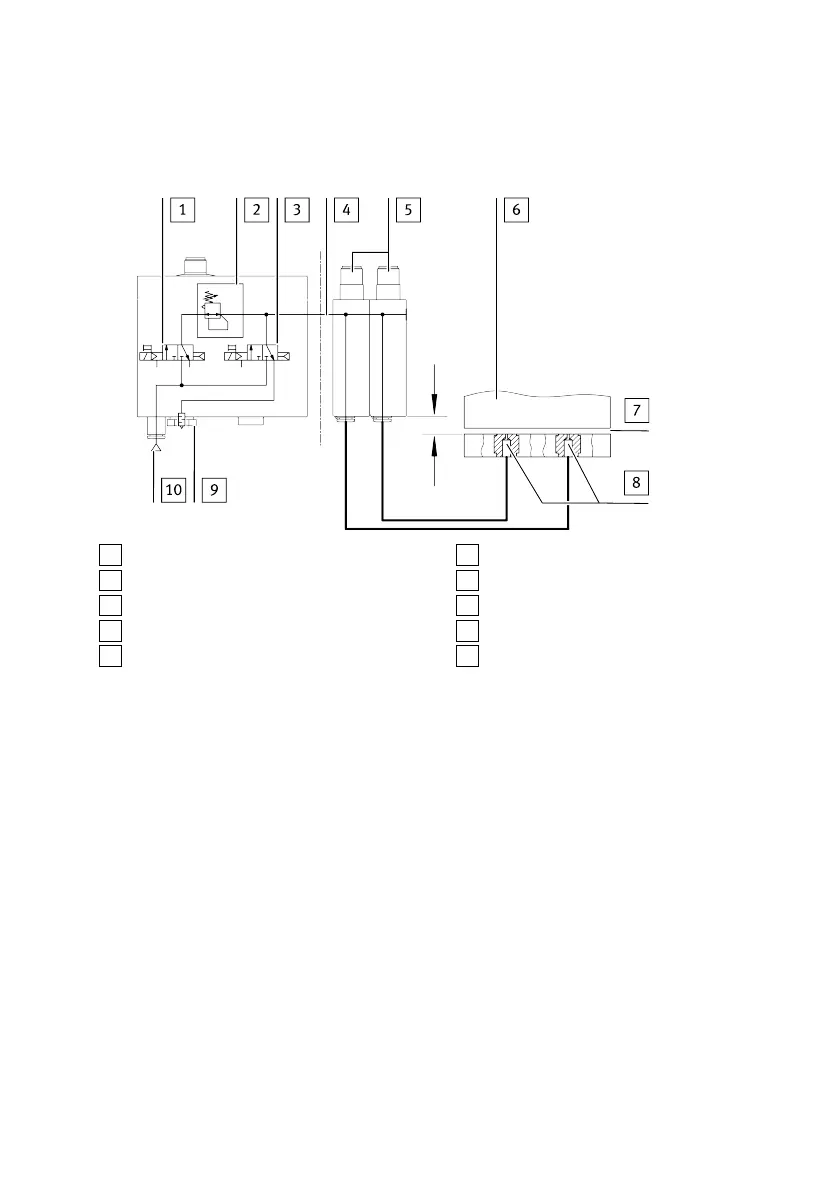

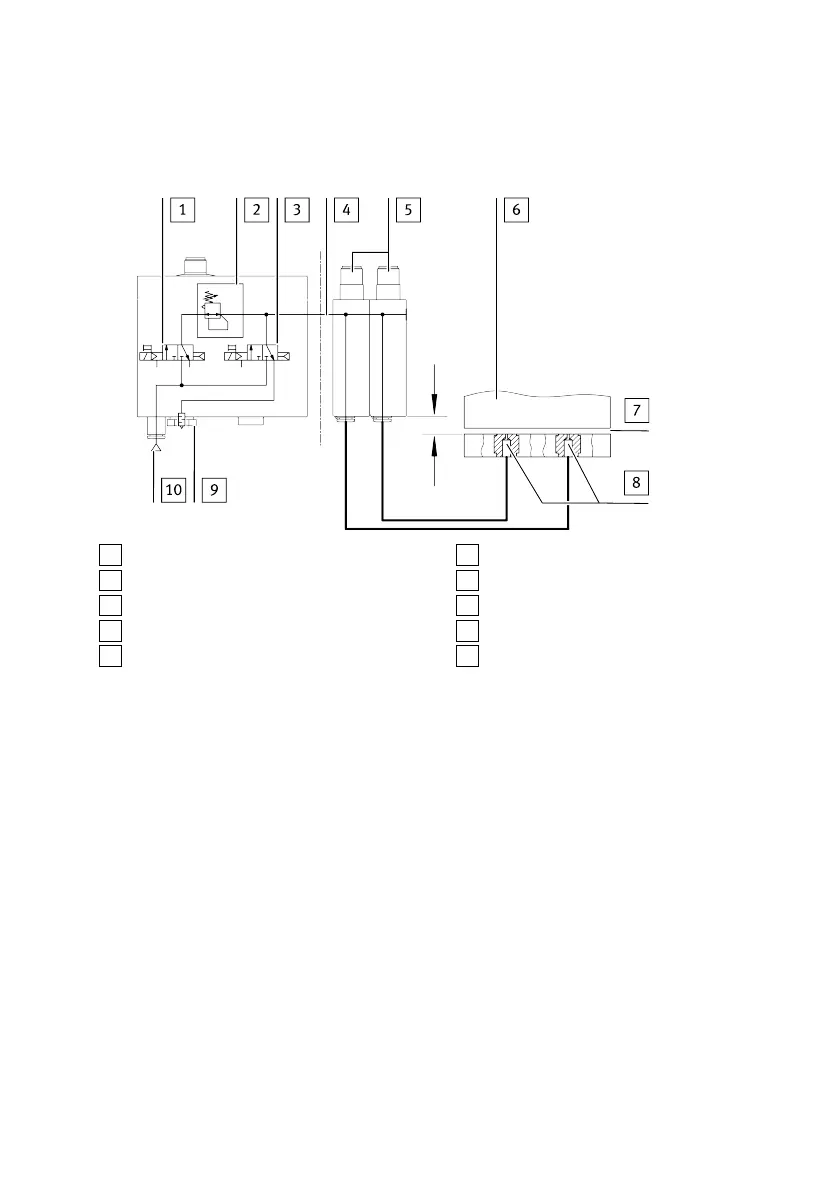

switching measuring and exhaust air. Up to 4sensor modules contain the sensory functions. The

sensor modules can be operated both individually and in combination with the control module.

1

3/2-way valve (instrument air)

2

Pressure regulator

3

3/2-way valve (exhaust air)

4

Supply pressure

5

Sensor modules (pneumatically linked)

6

Object (example)

7

Air gap

8

Measuring nozzles (1 per sensor module)

9

Vent screw

10

Supply port for operating pressure

Fig. 6 Configuration with a control module and two sensor modules

The compressed air flows from the sensor modules to the measuring nozzles. If the object is very close

to a measuring nozzle, the air gap is very small and only a small amount of air flows through. As the

object gets further away, the air gap becomes larger and more air flows through. The change in flow

rate is detected by the sensor modules, converted into a distance-correlated value and displayed

(speed measuring method with ejector).

5.2.4 Analogue output

Analogue output

The analogue output (distance monitoring) is available as voltage output 0…10V or 1…5V or as

current output 4…20mA.

Scaling of the analogue output

The analogue output at pin 2 of the electrical connection can be scaled. In the delivery status the out-

put characteristic curve at its end points (0…10V or 1…5V or 4…20mA) is allocated to the value

0…300 displayed correlated to the distance.

To scale the output characteristic curve, the effective range can be adapted for the distance input vari-

able è Tab. 7. The scaling of the analogue signal means that only a limited sensing range affects the

entire stroke of the analogue output (zoom function). This zoom function can be used to improve the

resolution of the analogue output.

Product overview

15Festo — SOPA — 2020-04

Loading...

Loading...