FLAMIC S.R.L. 5 Via dell’Artigianato, 36035 Marano Vicentino (Vicenza) - Italy

55

Dough sheeter SF450 - SF500 - SF600 Operation and maintenance manual (translation of original instructions) – Ed. 10/2016

Rev.02 10/2017

All rights reserved. Reproduction in whole or in part of this manual is prohibited.

The following hazards and relative risks are also associated with the machine:

hazards of an electrical nature:

E. electrocution: by contact with live parts (for example, inside the electrical enclosure)

hazards associated with instability

F. tipping hazard (e.g. if moved with the tables fully raised)

associated with the machine being started accidentally

G. loss of balance and falling in the event that, with the machine already enabled for operation, a person were

to lean on a conveyor belt and another person were to inadvertently press a start or reverse control (lever,

joystick, pedal)

associated with hygiene

H. damage to people's health by contact with mould, perishable substances etc. due to the presence of

insects rodents etc.

I. unacceptable alterations to the food product (for example contamination by micro-organisms or from

foreign substances/matter)

associated with the failure to comply with ergonomic principles

J. bodily injury / harm as a result of incorrect posture and/or movement(s).

K. lifting and handling of heavy loads (manual handling of large quantities of dough,

installation/removal/handling of tables and cutting unit etc.)

associated with inhaling dust

L. possible damage to the respiratory tract (rhinitis, lachrymation, asthma etc.), if the operator, when

sprinkling the dough with flour fails to take the precautions outlined in this manual and causes large amounts

of dust to be dispersed into the air.

The related risks have been eliminated or minimized as much as possible by adopting the safety measures and

devices described in section 5.2.2, 5.2.3 and 5.3 and/or can be further reduced if the user takes the precautions

indicated in section 5.2.3, 5.2.4 and 5.3.

5.2.2 MACHINE SAFETY DEVICES

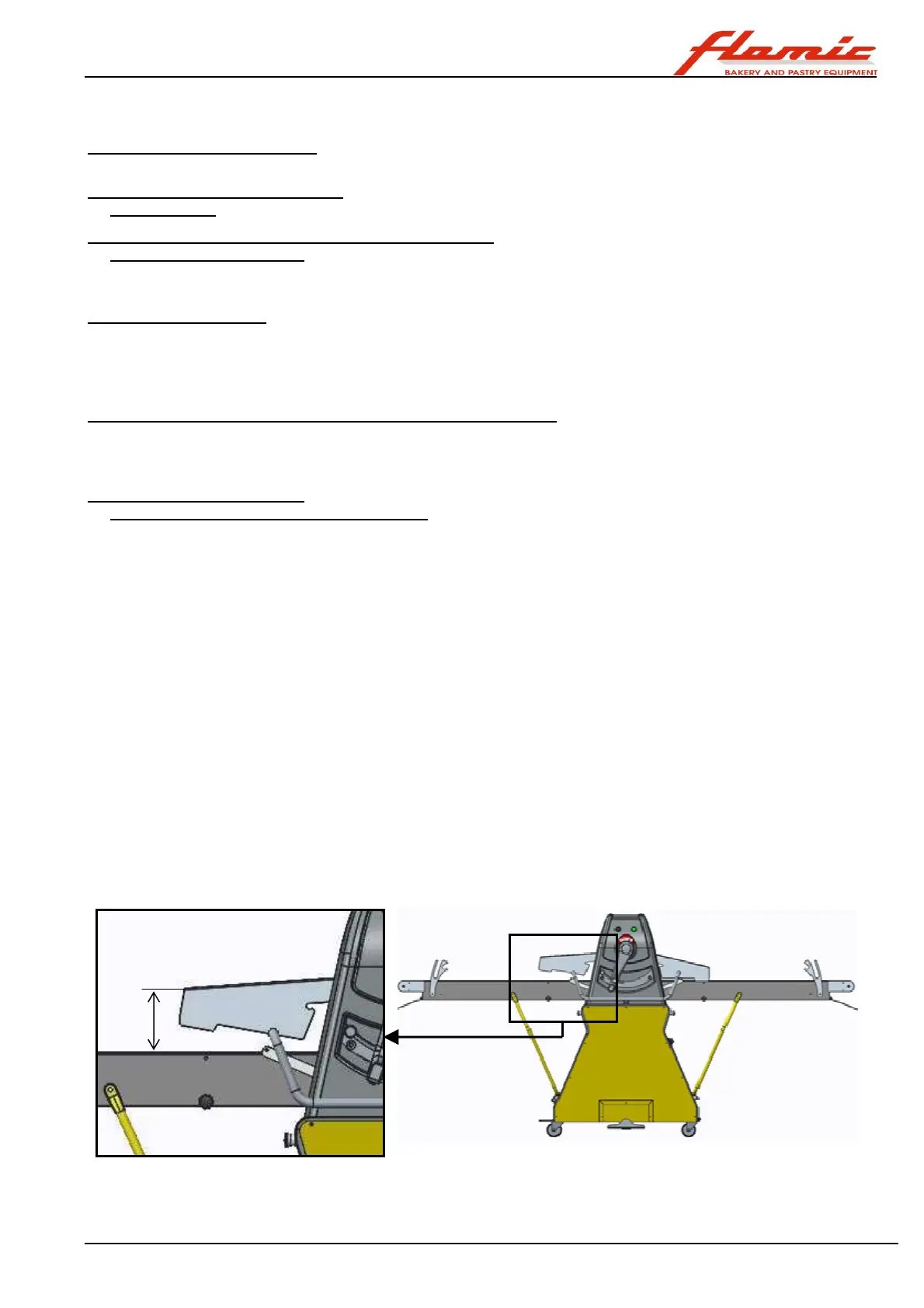

1. Interlocked mobile guards, each associated with a safety micro switch, positioned in order to protect

the rolling zones and, in general, the zones subject to the hazards indicated with the letter A in section 5.2.1.

They can be lifted from one end as they are able to rotate about a horizontal pin. They consist of a steel

plate in which slits have been made in to order to make the rolling area visible.

If a guard is raised, the associated micro switch, which has normally closed contacts, if forced open (positive)

causes all parts of the machine to stop.

The micro-switch trips when a guard is lifted and the distance D between the edge of the guard and the

conveyor belt (see Figure 46) exceeds a limit value Dmax, which must not, under any circumstances be

greater than:

- 70 mm for models SF500 and SF600

- 40 mm for model SF450

The machine must stop within a second of the micro switch tripping. This requirement is verified by Flamic on

the new machine before it is shipped.

In order to restart the moving parts after the machine was stopped, first lower the guard and then press the

enable button ref. 2 Figure 4.

Figure 46 - Interlocked guards in front and behind the rolling zone

D

Loading...

Loading...