Maintenance

PERFORMANCE

TEST

5.

Set the Current Source for zero

mA

and disconnect it

from the 8840A.

6-8.

AC Current Test (Option

-09

Only)

The following procedure may

be

used to test the mA AC

function:

Ensure the

8840A is on and warmed up for at least

1

hour.

Select the mA AC function.

Connect the AC Current Source to provide a current

input

to

the 2A and

LO

INPUT terminals.

If

an ac

current source is not available, the functionality of the

8840A

can

be

checked at 10

rnA

by using

a

Fluke

5200A

set

at lOOV and

COMX~~

to the 884OA 2A

terminal through a 10

kS2,

2W,

1% resistor.

For each step in Table

6-7,

set the AC Current Source

for the indicated input and verify that the displayed

reading is within the limits shown for each reading

rate.

Set the AC Current Source to Standby and disconnect

it from the

8840A.

CAUTION

To avoid uncalibrating the

8840A,

never

cycle power on

or

off while the

CAL

ENABLE

switch

is

on.

NOTE

If

U220

is

replace4 perform the Erase Cali-

bration Memory procedure (located later in

this section) before attempting calibration.

Failure

to

do

so

may

result in an ERROR

29

on the 8840A front panel display.

The 8840A features closed-case calibration using known

reference sources. The 8840A automatically prompts you

for the required reference sources, measures them, calcu-

lates correction factors, and stores the correction factors in

the nonvolatile calibration memory.

Closed-case calibration has many advantages. There are no

parts to disassemble, no mechanical adjustments to make,

and if the IEEE-488 Interface is installed, the

8840A can

be

calibrated by an automated instrumentation system.

The 8840A should normally

be

calibrated on a regular

cycle, typically every 90 days or

1

year. The frequency of

the calibration cycle depends on the accuracy specification

you wish to maintain. The

8840A should also be calibrated

if it fails the performance test or has undergone repair.

To

meet the specifications in Section

1,

the 8840A should be

calibrated with equipment meeting the minimum

specifications given in Table

6-1.

The following paragraphs first present a basic calibration

procedure. This is followed by

a

description of advanced

features and special considerations, and by a description of

remote calibration using the

IEEE-488

Interface.

6-10.

Basic Calibration Procedure

The lbasic calibration procedure consists of the following

four parts. These parts must

be

performed in the order

shown.

1.

Initial Procedure.

2.

AID

Calibration.

3.

Offset and

Gain

Calibration for each function and

range.

4. High-Frequency AC Calibration (True RMS AC

option only).

Normally, it is recommended that the entire calibration

procedure

be

performed. However, under some circum-

stances the earlier parts may

be

omitted. For example,

if

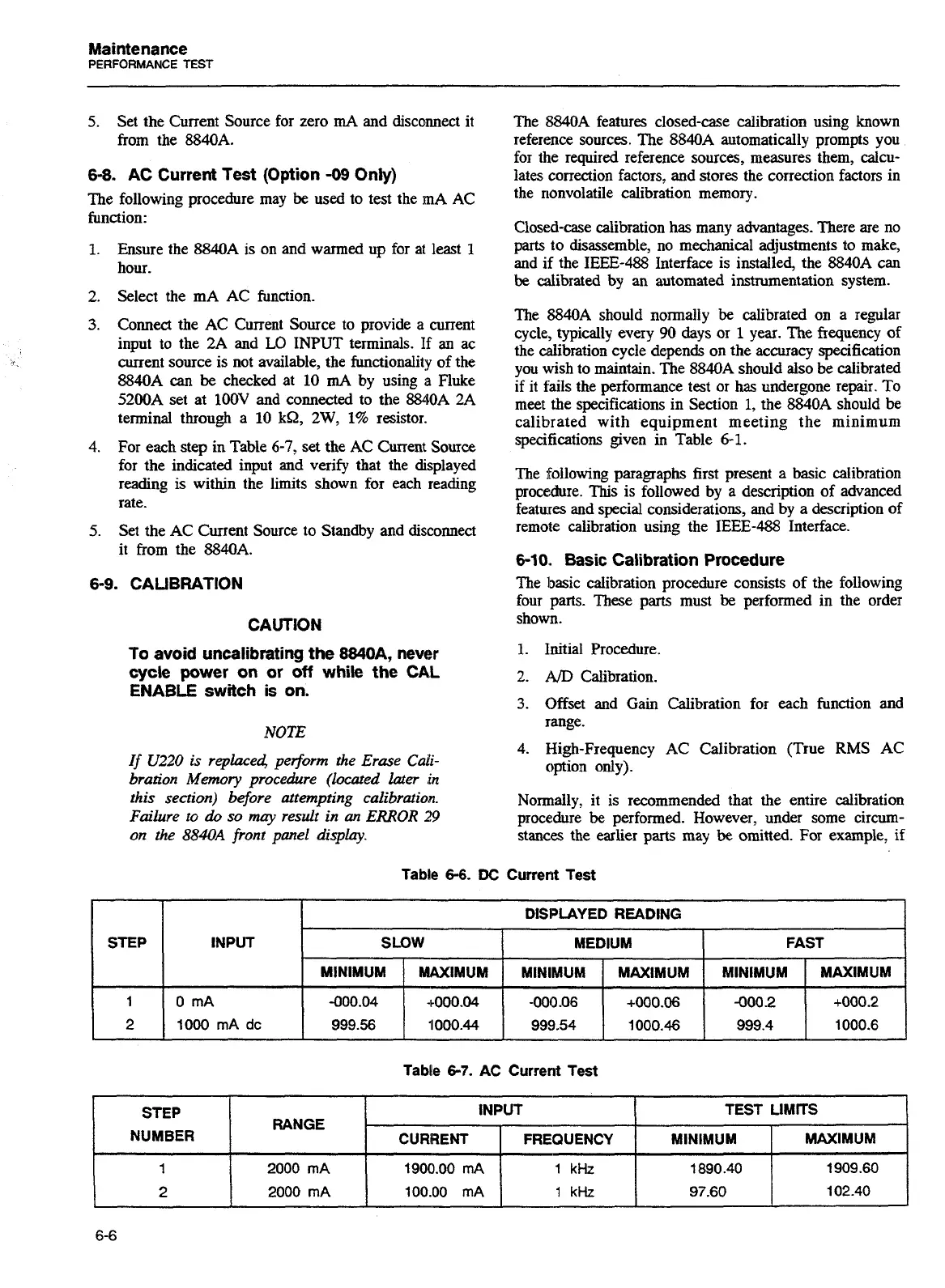

Table

6-6.

DC

Current Test

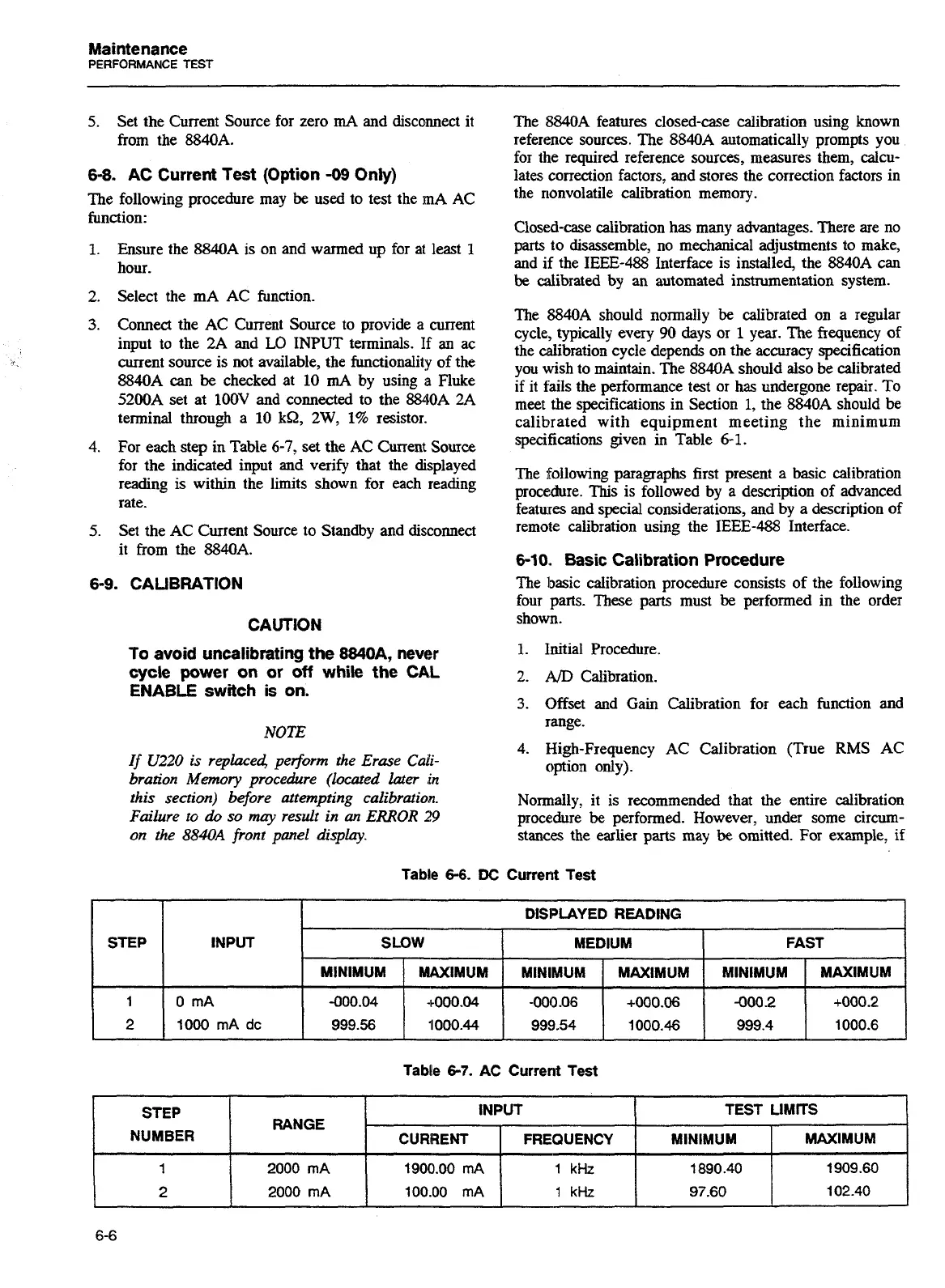

Tabie

6-7.

AC Current Test

STEP

1

2

INPUT

0 mA

1000 mA

dc

STEP

NUMBER

1

2

DISPLAYED READING

RANGE

2000 mA

2000 mA

SLOW

MINIMUM

-000.04

999.56

INPUT

MAXIMUM

+000.04

1000.44

MEDIUM

TEST

LIMITS

CURRENT

1900.00 mA

100.00 mA

FAST

MINIMUM

-000.06

999.54

MINIMUM

1

890.40

97.60

FREQUENCY

1

kHz

1

kHz

MINIMUM

-000 2

999.4

MAXIMUM

+000.06

1000.46

MAXIMUM

1 909.60

102.40

MAXIMUM

+000.2

1000.6

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...