Maintenance

CAUBRATiON

NOTE

6-27.

DISASSEMBLY PROCEDURE

When erasing calibration memory, it is good

practice to send the communds

C3

and

CO

in

WARNING

the same command string. Sending

C3

by itself

TD

AVOID ELECTRIC SHOCK, REMOVE

could lead to accidentally erasing calibration

VE POWER CORD AND TEST LEADS

memory, since the

C3

command does not time

&FORE DISASSEMBLING THE IN$TRU-

out

as does the

ERASE

button.

MEW.

OPENING COVERS

MAY

EXPOSE

LIVE PARTS.

CAUTION

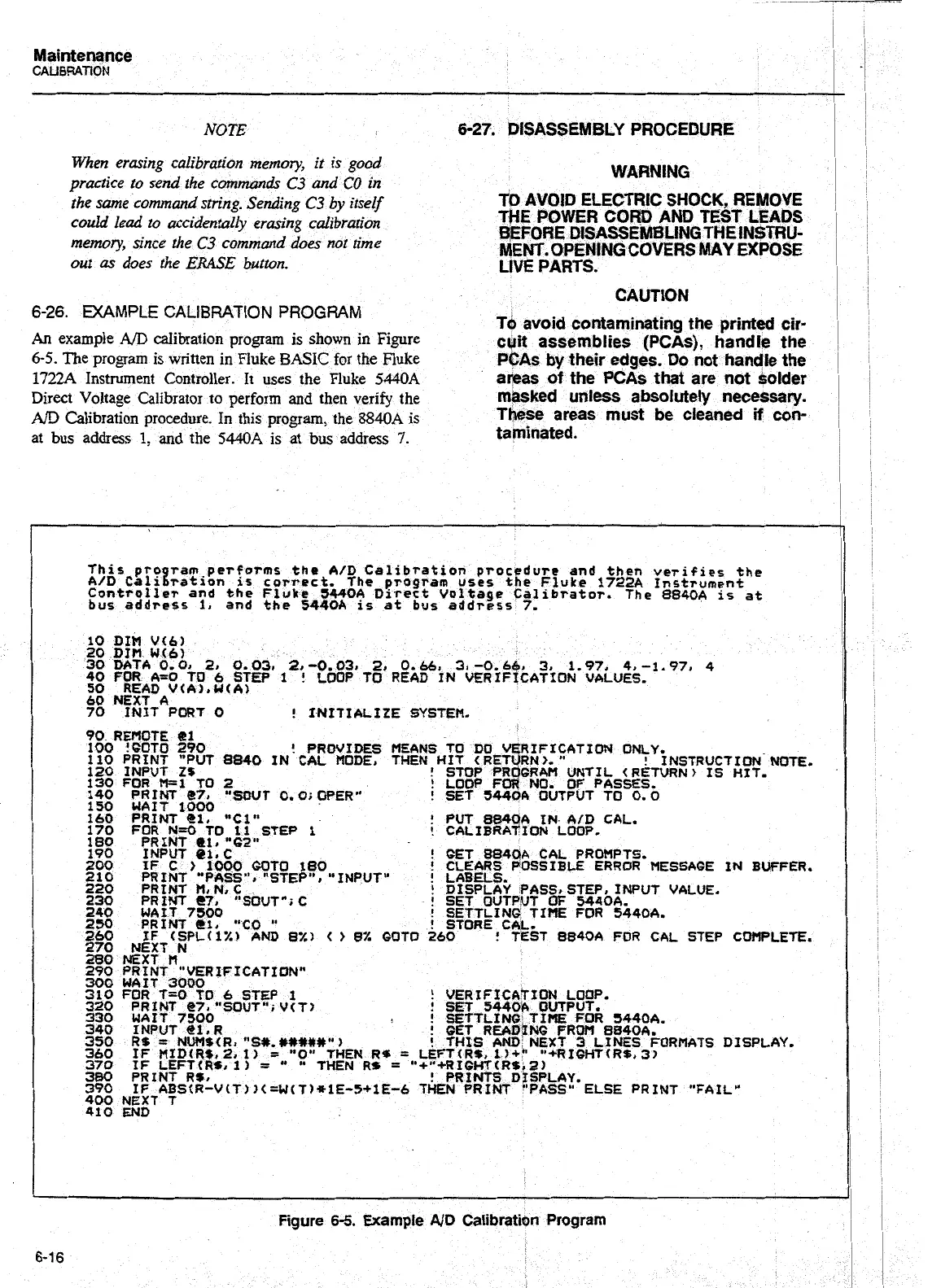

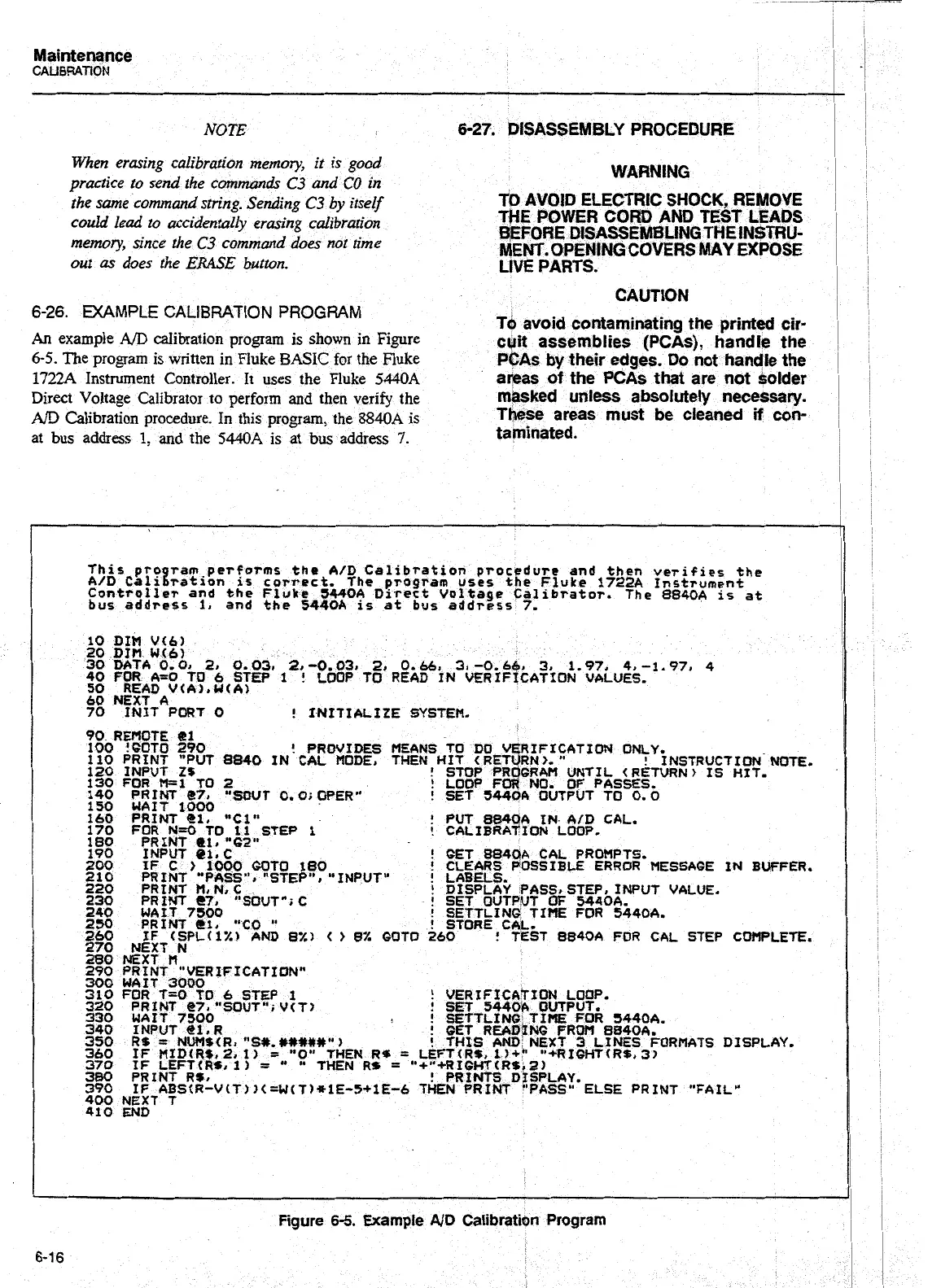

6-26.

EXAMPLE CALIBRATION PROGRAM

Tcb avoid contaminating the printed cir-

An

example

A/D

calibration program is shown in Figure

cyit assemblies (PCAs), handle the

6-5.

The program is written in Fluke

BASIC

for the Fluke

PCAs by their edges. Do not handle the

1722A

Instrument Controller.

It

uses the Fluke

5440A

areas

of

the PCAs that are not solder

Direct Voltage Calibrator to perform and then verify the

m&ked unless absoIutely necessary.

A/D

Calibration procedure. In this program, the

8840A

is

These areas must be cleaned

if

con-

at bus address

1,

and

the

544.014

is

at

bus

address

7.

taminated.

This

pro

ram performs the

A/D

Calibration procedure and then verifies

the

AD

~liraton

1s

correct.

The

program

uses

the Fluke

172

Instrument

Controller and the Fluke

5440A

Direct Voltage Calibrator. The 8840A

is

at

bus address

1,

and the

5440A

is at bus address

7.

10

DIM

V(6)

20

DJH

Wt6)

30

DATA

0-

01

21

0.031

2r

-0.03,

2,

0.661

3.

-0.6

3,

1-97,

4,

-1.97,

4

40

FOR As0

TO

6

STEP

1

!

LOOP

TO

READ

IN VERIF~~ATION VALUES.

50

READ V(A).U(A)

60

NEXT

A

70

INIT

PORT

0

!

INITIALIZE

SYSTEM.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...